Effect of Flux in PCBA Production

PCBA flux is usually composed of rosin mixture, which is an auxiliary material to ensure the smooth welding process Welding is the main process of electronic assembly Whether PCBA flux auxiliary materials are used for welding The main function of the flux is to remove the oxides on the surface of the solder and welding substrate, so that the metal surface can reach the necessary cleanliness Prevent the surface from re oxidation during welding, reduce the surface tension of solder, and improve welding efficiency The efficiency of flux directly affects the quality of electronic products

In general, military and life support electronic products (such as satellites, aircraft instruments, submarine communications, life support medical equipment, weak signal testing instruments, etc.) must use detergents. Non clean or clean flux can be used for other types of electronic products (such as communication, industrial equipment, office equipment, computers, etc.); Generally speaking, household appliances and electronic products do not need to use cleaning flux or RMA (medium active) rosin type flux.

Flux is an important raw material for PCBA processing and an indispensable auxiliary material for PCBA welding. The quality of flux can even directly affect the welding quality. Here is a brief introduction to the role of Pat Technology as a flux in Guangzhou PCBA professional processing plant.

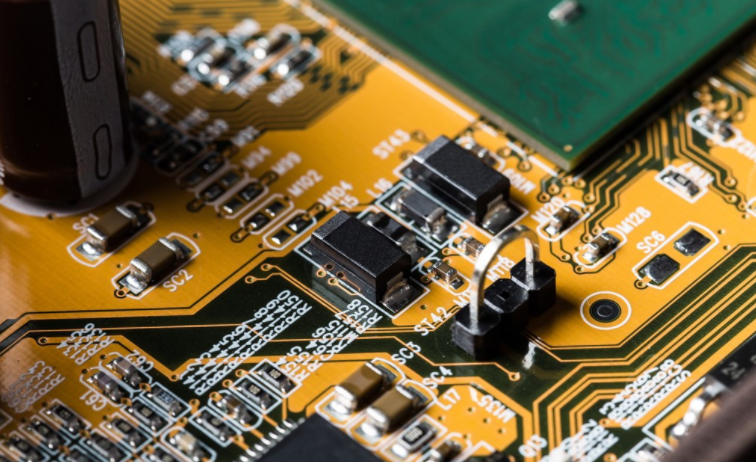

PCBA flux

1. Remove the oxide on the welding metal surface

In normal air environment, there are usually some oxides on the surface of welding metal. During the welding process, these oxides will affect the wettability of the solder, thus affecting the normal welding process. This, the flux needs to be oxidized to reduce, so that the welding of PCBA processing can be carried out normally.

2. Prevent secondary oxidation

PCBA needs to be heated during welding However, during the heating process, the metal surface will oxidize rapidly due to the temperature rise At this time, it is necessary to use flux to prevent secondary oxidation

3. Reduce the tension of molten solder

Due to the physical form, there will be some tension on the melted solder surface. The surface tension will cause the speed of solder flow to the welding surface, thus affecting the normal wetting process. At this time, the role of solder is to reduce the surface tension of liquid solder and significantly improve the wetting efficiency.

In PCBA processing, many engineers try to control the amount of flux used. However, in order to obtain good welding efficiency, more flux is sometimes required. In the selective welding process of PCBA processing, engineers often only pay attention to the welding results, not the flux residues.

Most flux systems use a glue drip device. To avoid reliability risk, the flux selected for selective welding should be inert when inactive, that is, inactive.

Adding more flux will create a potential risk of penetration into the SMD area and residues. In the welding process, there are some important parameters that will affect the reliability. The most critical is that the inactive part will be formed when the flux penetrates into SMD or other processes at a lower temperature. Although this may not have a negative impact on the final welding results in the process, when the product is in use, the combination of unstarted flux components and humidity will produce electromigration, making the ductility of the flux a key parameter.

PCBA

A new development trend of solder for selective welding is to increase the solid content of solder, so as to form higher solid content by using less solder Generally, the welding process requires 500-2000mg of solder solid/in2. In addition to the truth that the PCBA flux can be controlled by adjusting the parameters of the welding equipment, and the actual situation may be more complex The ductility of flux is very important to its reliability, because the total amount of dry solid of flux will affect the welding quality

he above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.