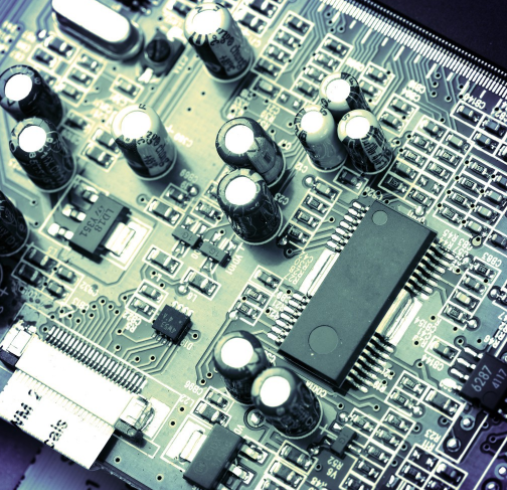

About PCBA welding type and method

In PCBA manufacturing, two common welding methods are reflow and wave soldering

What are the functions of reflow soldering, wave soldering and their differences in PCBA manufacturing?

1. Reflow soldering: refers to the process of soldering electronic components on a PCB by heating and melting the solder paste pre coated on the pad to electrically interconnect the pins or solder ends of electronic components pre installed on the pad with the pad on the PCB Reflow soldering is usually divided into preheating zones Heating area and cooling area

Reflow soldering process: printing paste>installing components>reflow soldering>cleaning

2. Peak welding: use a pump to spray molten solder into solder peaks, and then the pins of electronic components to be welded pass through the solder peaks to realize the power interconnection between electronic components and PCB boards. Peak welding includes spraying, preheating, tin furnace and cooling.

Peak welding process: 挿 parts>solder coating>preheating>peak welding>shortcut>inspection.

3. Difference between peak weld and reflow weld:

1) Peak welding is a welding peak formed by melting tin to weld parts; Reflow soldering is to use high-temperature hot air to form reflow molten tin to solder components.

2) During reflow soldering, there is solder in front of PCB. After welding, only the coated solder paste is melted for welding. During peak soldering, there is no solder in front of the PCB. The solder peaks generated by the welding machine cover the solder on the required pads to complete the welding.

3) Reflow soldering is applicable to chip electronic components, and wave soldering is applicable to pin electronic components.

PCBA welding

Peak soldering and reflow soldering are two important processes in PCBA manufacturing. The result of welding determines the quality of PCBA products.

Welding is a main connection method in PCBA manufacturing. Welding related issues should be considered at each stage of the PCBA manufacturing process, which is related to the quality level of PCBA.

1. Meaning of welding

Welding is a process in which two or more separate workpieces are connected into a whole in a certain form and position. You can use the heat. Pressure or other methods, with or without filler, rely on atomic diffusion and bonding to achieve permanent strong bonding between two metals.

2. Classification of welds

Welding can generally be divided into three categories: fusion welding. Pressure and soldering.

1) Melting: In the welding process, the welded joint is heated to the melting state, and the welding method can be completed without pressure. For example, arc welding. Gas and plasma welding, etc.

2) Pressure welding: During welding, pressure must be applied to the welding parts to complete the welding method. Pressure welding can be heated or not. For example, ultrasonic welding. Pulse and forging.

3) 釺 welding: use metal materials with lower melting point as 釺 welding data, heat 釺 welding materials and 釺 welding pieces to a temperature higher than 釺 welding point but lower than the melting point of the base metal, wet the base metal with liquid 釺 welding data, fill the gap between joints, and diffuse with the base material to realize the connection of 釺 welding pieces. Such as flame welding. Resistance welding and vacuum welding. According to the melting point of welding data, they are also divided into soft welding melting point (lower than 450 ℃) and hard welding melting point (higher than 450 ℃).

PCBA

In PCBA manufacturing, after checking the welding quality of electronic components, disassemble and weld the electronic components that are not welded correctly However, in order to remove the electronic components with incorrect soldering without damaging other components and PCB, it is necessary to master the manufacturing and disassembly skills of PCBA

1. Basic principles of disassembly:

Before disassembly, it is very important to understand the characteristics of the original welding points and do not start easily.

1) Do not damage the components to be removed. Wires and surrounding parts;

2) During welding and disassembly, the bonding pad and the printing guide rail on the PCB shall not be damaged;

3) For electronic components judged as damaged, the pins can be cut before disassembly to reduce damage;

4) Try to avoid moving other original equipment, and if necessary, do a good job of recovery.

2. Key points of disassembly and welding:

1) The heating temperature and time shall be strictly controlled to avoid damaging other parts under high temperature. Generally speaking, the time and temperature of disassembly is longer than that of welding.

2) Do not use excessive force during welding and disassembly. The packaging strength of the components decreases at high temperatures, resulting in excessive stretching. Shake it. Twisting can damage components and gaskets.

3) Remove the solder at the disassembly site. The tin absorbing tool can be used to absorb tin and directly pull out components, reducing disassembly time and the possibility of damaging PCB.

3. Disassembly method:

1) Splitting spot welding

For the resistance elements installed horizontally, the two welding points are far apart, which can be heated respectively through the electric cautery and pulled out point by point. If the pin is bent, use an iron to straighten it before removal.

During disassembly, stand the PCB upright, heat the pin solder joints of the components to be disassembled with an electric soldering iron, and gently pull out the pins of the components with tweezers or pointed clamps.

2) Centralized demolition

Because the pins of drain resistor are welded separately, it is difficult to heat them with a soldering iron at the same time. You can use a hot air welder to quickly heat several solder joints and pull them out once after the tin has melted.

3) Retention separation method

PCBA

First, use the tin absorbing tool to absorb tin from the separated solder joints. In general, components can be removed.

If multi pin electronic components are encountered, electronic thermal fans can be used for heating.

If it is a lapped component or pin, you can weld on the solder joint, open the solder joint with an electric burner, and then remove the pin or lead of the component.

If it is a hook welding component or pin, first remove the solder on the solder joint with an electric soldering iron, then heat it with an electric soldering iron to melt the residual solder under the hook, and at the same time lift the pin towards the hook line with a spatula. Do not pry hard to prevent molten solder from splashing eyes or clothes.

4) PCBA cutting and PCBA welding methods

If there is any remaining pin and wire of the removed component, or if it is determined that the component is damaged, the component or wire can be cut off before removing the wire head on the pad.

4. Precautions for re welding after disassembly

1) The pins and wires of the re welded parts shall be consistent with the original pins and wires as far as possible;

2) Passing through the blocked pad hole;

3) Restores the moved component to its original state.