Electrostatic protection of circuit board and baking time and temperature

·In the process of PCBA processing, it is necessary to improve the anti-static ability of the product itself. Specific electrostatic protection measures include:

Electrostatic sensitive components, integrated circuits, electronic components and electronic equipment with anti-static protection design shall be selected.

·Adopt electrostatic shielding and grounding design. For sensitive parts and sensitive components, electrostatic shielding measures such as protective covers, covers and sheets shall be taken to reduce the mechanical, inductive and discharge hazards of static electricity. The existence of isolated conductors shall be avoided as far as possible.

·Ensure electrostatic safety of equipment, facilities and workplaces. Keep all facilities and systems in the workplace properly and effectively grounded; Control the static voltage of each point in the operation area within the allowable range of the standard.

·Formulate and implement strict electrostatic safety operation specifications and electrostatic safety management specifications.

What is the baking time and temperature of the circuit board

Before the SMT chip processing plant goes online, the circuit board needs to be baked. If the circuit board is vacuum packed correctly, it can be assembled without baking. If it has been placed for a period of time, it is recommended to bake at 120-130 ° C for about 40-60 minutes, which may be the appropriate temperature and time, but it also depends on the metal surface treatment. Some treatments are not suitable for baking at all.

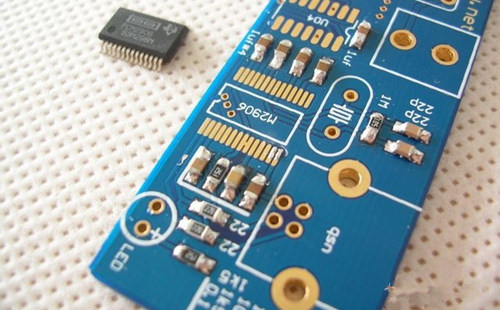

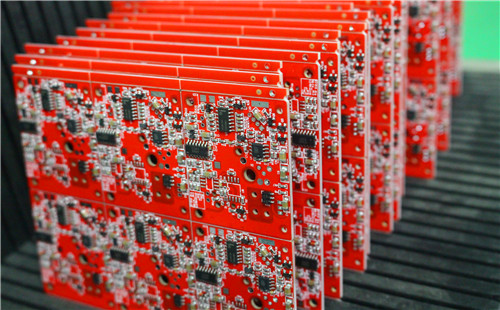

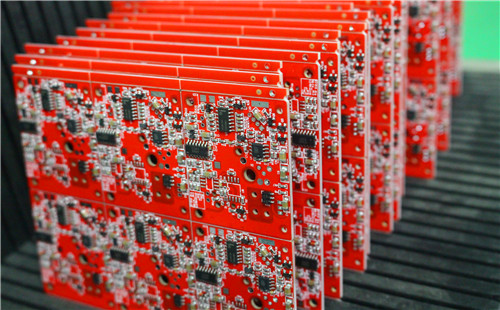

Circuit board

The IPC has no such regulations, because there are too many changes in products, materials, etc., to formulate rules at all. 120-130 ° C will be set because the water volatilization temperature is 100 ° C, and 40-60 minutes is due to the previous experience that the water content of FR4 material can be reduced to a very low stable value under this condition.

If baking can be added before general circuit board assembly, it should reduce the risk of moisture residue and board bursting. However, due to the diversity of current PCB metal treatment methods, some treatments are not suitable for baking, so no one will stipulate that baking is necessary. Besides, most circuit board manufacturers hope to assemble circuit boards without baking, which can save time. However, it must be noted that if the soft board material is easy to absorb water, it is better to bake it. In addition, even if the package is good, if it is left in a non dry environment for a long time, it is better to bake and then assemble it, otherwise it is easy to cause problems. However, the baking should be conducted as long as Kaifeng is kept, because the material characteristics and environmental factors have too much influence, so it is difficult to set a standard.

If silver oxide or organic solder mask is used for metal treatment, it is difficult to require baking before assembly, because baking does have the opportunity to damage the copper surface protection and affect the solderability of the circuit board. The above is for your reference. PCB manufacturers, PCB designers and PCBA processors will explain the static protection of PCB and the baking time and temperature.