Circuit board factory: what is the basic composition of the mounting machine

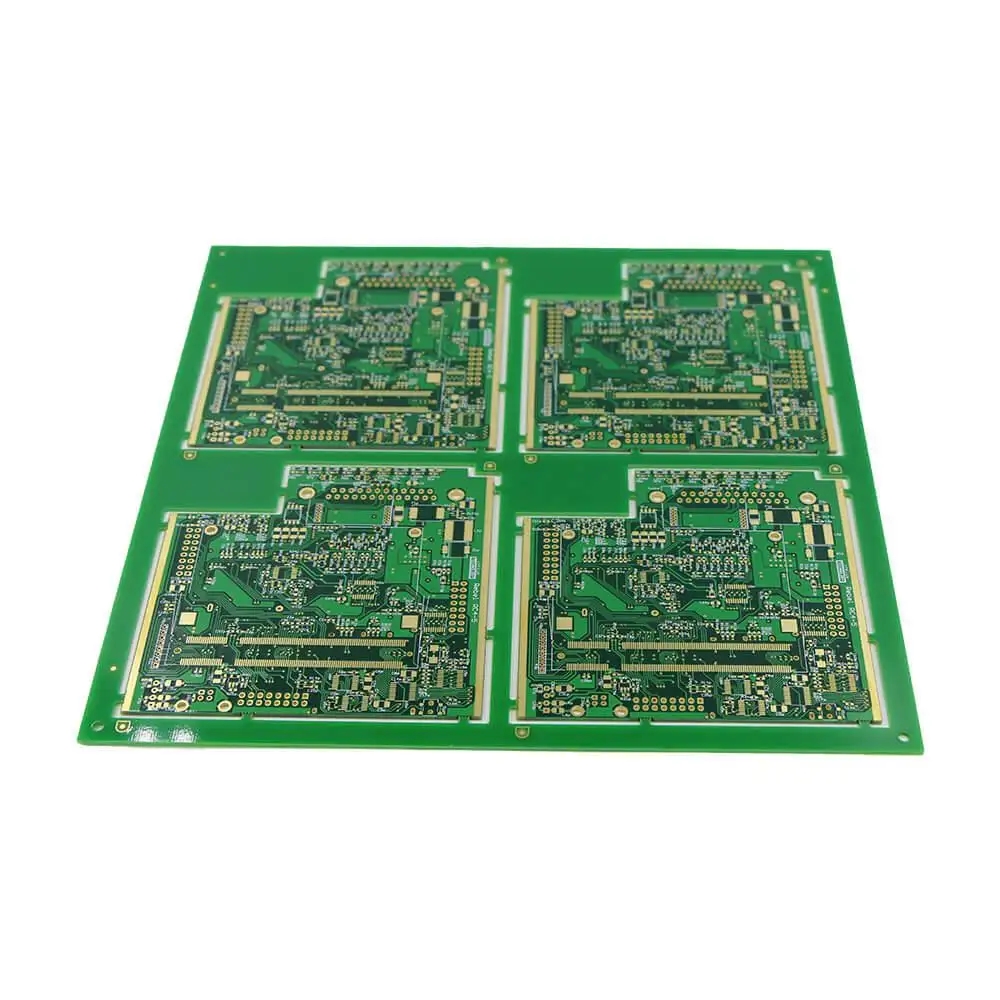

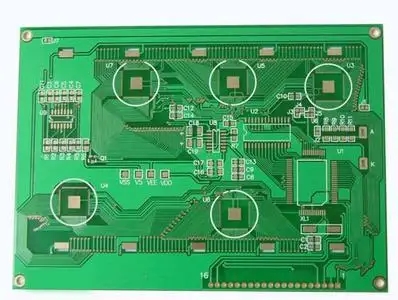

Circuit board manufacturing, circuit board design and PCBA processing manufacturers will explain to you what is the mounter and its basic components

The SMT machine is also called "mounting machine" or "surface mount system". In the SMT production line, it is configured behind the solder paste printer or dispensing machine. The SMT mounting machine is a kind of equipment that can accurately attach various kinds of chip type SMC/SMDs to the corresponding positions on the PCD surface printed with solder paste or patch adhesive. It is the core and key equipment that constitutes the SMT assembly system or SMT production line and determines the system assembly efficiency and assembly function. The placement machine can be divided into semi-automatic and full-automatic according to the degree of automation; According to speed, it can be divided into medium speed, high speed and super high speed; According to the patch structure, it can be divided into Gantry type, Turret type and composite type; According to functions, it can be divided into high-speed machine, universal machine and other different types. There are some differences in the performance and functions of various types of mounters, but the basic functions are the same.

Learn the basic components of the mounter in detail

The automatic placement machine is used to realize high-speed, high-precision automatic placement of components. It is the most critical and complex equipment in the entire SMT production.

The main functional components of the full-automatic placement machine include the equipment body, the chip element device supply system, the placement head and its drive positioning device, the PCB transmission and positioning device, the Feeder, the electrical control system, the computer control system, the optical detection system, etc.

SMT is the main key technology and work focus in the whole SMT manufacturing process, which uses high-precision automatic placement equipment to accurately place the surface adhesive components on the solder pad of PCB printed with solder paste through computer programming. Therefore, the quality and accuracy of SMT production placement machine are crucial.

PCB manufacturers, PCB designers and PCBA processors will explain to you what the SMT machine and its basic components are.