PCBA processing: detailed explanation of the operation method of lead-free soldering station

The lead-free soldering station is widely used as a soldering tool, from the maintenance of common electronic appliances to electronic integrated circuits and chips, but it is most commonly used for soldering PCB circuit boards in electronic factories. Especially suitable for lead-free precision electronic welding operation. 1. Before using the welding table, check whether the cleaning sponge is soaked with water. First, clean the sponge with wet water, and then squeeze out the excess water. In this way, the lead-free soldering head can get a good cleaning effect. If a non wet cleaning sponge is used, the welding tip will be damaged and tin will not be coated. 2. Protective welding station for welding work Use cleaning sponge before welding

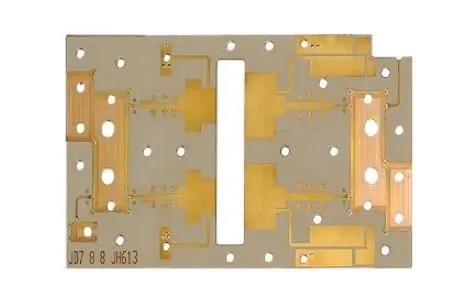

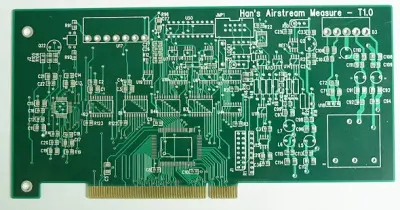

The lead-free soldering station is widely used as a soldering tool, from the maintenance of common electronic appliances to electronic integrated circuits and chips, but it is most commonly used for soldering PCB circuit boards in electronic factories. Especially suitable for lead-free precision electronic welding operation.

1. Preparation before using the welding table

You must first check whether the cleaning sponge is soaked with water, first clean the sponge with wet water, and then squeeze out the excess water. In this way, the lead-free soldering head can get a good cleaning effect. If a non wet cleaning sponge is used, the welding tip will be damaged and tin will not be coated.

2. Protection during welding

Before welding the welding station, clean the impurities on the welding tip with a cleaning sponge, so as to ensure that the quality of the welding spot will not show false welding and false welding, which can slow down the oxidation rate of the welding tip. Therefore, ensuring the cleanliness of the welding tip can prolong the service life of the welding tip.

Lead free soldering station

3. Protection of welding station after welding

First adjust the temperature to 300 ℃, then clean the welding tip, and add a layer of new solder for protection, so that the welding tip can be isolated from the air by relay protection, and the welding tip will not react with oxygen in the air.

4. Protection when the welding station is not used

When the welding station is not used, the welding tip shall not be kept at high temperature for a long time, which will convert the flux on the soldering tip into oxide, thus greatly reducing the thermal conductivity of the soldering tip. Turn off the power when the welding station is not in use (for the welding station without temperature control and automatic sleep function).

Functions of lead-free soldering station

1. The temperature locking function of the welding station shall not have large deviation.

2. The password lock function prevents workers from changing the welding temperature at will due to misoperation.

3. Antistatic function, precision chip welding process requires strict anti-static requirements.

4. Automatic sleep function, in order to extend the life of the soldering head.

5. Temperature compensation function, fast temperature rise and return.

6. Digital display temperature, easy to adjust.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the operation methods of lead-free soldering stations.