PCB double-sided copy method and drawing effect review

p> In the process of scientific and technological realization, PCB copying is only to scan the PCB to be copied and record the detailed component positions. This n remove the components to make a bill of materials (BOM) and arrange material proposal, blank board: the scanning image is processed by the copy board software and restored to the PCB drawing folder, and then the PCB file is sent to the plate making factory to make the PCB Board testing and debugging can be carried out

The specific steps are as follows: PCB copying:

The first step is to get a PCB First, record the model, parameters, and positions of all important components on the paper, especially the direction of the diode, the triode, and the IC notch It is best to use a digital camera to take two pictures of the original element position Now PCB boards are getting better and better. Some diodes and triodes are invisible

The second step is to remove all laminates and remove tin from the liner holes Clean PCB alcohol and put it into the scanner When the scanner scans, it needs to add slightly more scanning points to obtain clearer images Then, gently polish the top and bottom layers with water gauze until the copper film is bright, put it into the scanner, start PHOTOSHOP, and scan the color of the two layers Please note that the PCB must be placed horizontally and vertically in the scanner, otherwise the scanned image will not be available

The third step is to adjust the contrast and brightness of the canvas to make the part with copper film and the part without copper film have strong contrast, and then turn the second image into black and white to check whether the lines are clear. Otherwise, repeat this step If clear, save the picture as a black and white bone morphogenetic protein file. BMP and robot. BMP If there is any problem with the picture, you can also use PHOTOSHOP to fix and correct it

The fourth step is to convert the two BMP files into PROTEL files and transfer them to two layers in PROTEL For example, the positions of pads and vias after two layers are basically the same, indicating that the previous steps have been completed If there is any deviation, repeat the third step Therefore, copying PCB is a work that requires patience, because a small problem will affect the quality and matching degree of copied PCB

The fifth step is to convert the top BMP to the top PCB board, pay attention to converting it to a silk layer, which layer is yellow, then you can trace the line on the top layer, and place the equipment according to the drawing in the second step After painting, delete the silk layer Continue to repeat until all layers are drawn

The sixth step is to transfer the top PCB board and robot PCB boards can be combined into a picture in PROTEL

Step 7: use a laser printer to print the TOP LAYER and BOTTOM LAYER transparencies (1:1 ratio), place the film on the PCB, and compare whether there are any errors If it's right, you're done A copy of the original board was born, but it was only half done It is also necessary to test whether the electronic technical efficiency of the duplicate board is the same as that of the original board If so, then it is really finished If it is a multilayer board, it shall be carefully polished to the inner layer, and the copying steps from step 3 to step 5 shall be repeated at the same time Of course, the names of figures are different and should be determined according to the number of layers Generally, there are more double-sided boards than copy boards So the multi layer board copy board should be very careful and careful (the internal vias and non conductive holes are cause to problems)

Double-sided copying method:

1) Scan the upper and lower layers of the circuit board and save two BMP pictures.

2) Open the copy board software QuickPCB 2005, click "File" and "Open Underlay" to Open the scan image Use PAGEUP to enlarge the screen. See? Press PP to place a cushion, draw it with this software, and click "Save" to generate a B2P file

3) Click "File" and "Open Basemap" to open the scanned color map of another layer;

4) Click "File" and "Open" again to open the B2P file saved earlier. We can see the just copied PCB stacked on the same PCB in this photo The holes are in the same position, but the circuit connections are different So we press "Options" and "Layer Settings". Here, we turn off the display of lines and screen on the top layer, leaving only multi-layer through holes

5) The vias on the top layer are in the same position as the vias on the bottom image. Now, we can trace the bottom line like childhood Click Save again, and then the B2P file will have the top and bottom data

6) Click "File" and "Export as PCB Board File", you can get a file of a PCB with two layers of data. You can change the circuit board or reprint the schematic diagram, or directly send it to the PCB factory to produce a multi layer board copy board method:

In fact, the four layer board is to duplicate two double-sided boards, and the sixth layer board is to duplicate three double-sided boards Multilayer is daunting because we can't see internal cabling How do we view the inner layer of precision multilayer board- Layering Now there are many layering methods, such as chemical corrosion, knife cutting, etc, However, it is easy to divide too many layers and lose data Experience tells us that sanding is accurate When we finish copying PCB, we usually use sandpaper to polish the surface layer to expose the inner layer; Sandpaper is ordinary sandpaper sold in hardware stores. Generally, PCB boards are laid, and then sandpaper is pressed on the PCB boards Rub even on the board (if the board is small, you can also lay the sandpaper flat and press the PCB with one finger and rub it on the sandpaper) The key is to flatten and grind it evenly The silk screen and green oil are usually wiped off, and the copper wire and copper sheet should be wiped several times Generally speaking, the Bluetooth board can be erased in a few minutes, and the memory stick takes about 10 minutes; Of course, if you have great power, it will take less time; If your strength is not enough, it will take a little time Grinding is the most commonly used delamination solution and is economical We can use discarded PCB boards In fact, polishing the circuit board is not difficult in science and technology, but it is a bit boring It takes a little effort, and you don't have to worry about rubbing the board to your fingers

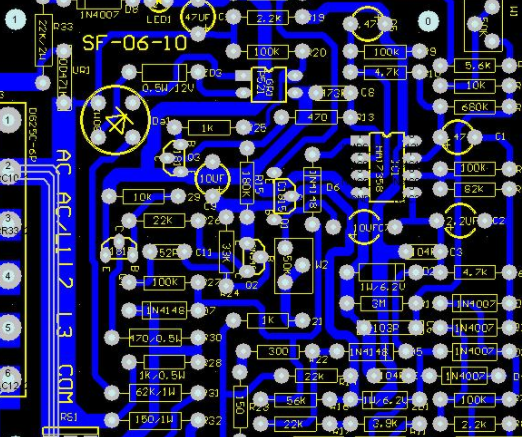

PCB drawing effect review

In the process of PCB board layout, after the system layout is completed, the PCB board should review the chart to see whether the system layout is reasonable and whether excellent results can be obtained It can usually be investigated from the following aspects:

1) Whether the system layout guarantees the rationality or superiority of the wiring During layout, it is necessary to fully understand and plan the direction of signal and power supply and grounding network

2) Whether the size of the printed board is consistent with the size of the processing drawing, and whether there are behavior marks This requires special attention Many circuit layout and wiring PCB board designs are beautiful and reasonable, but the positioning of the positioning connector is ignored, which makes the design circuit unable to connect with other circuits

3) Whether there is conflict between components in two-dimensional and three-dimensional space. Pay attention to the actual dimensions of the equipment, especially the height of the device When welding free components, the height shall not exceed 3mm

4) When the component layout is dense and orderly When arranging components, not only the signal direction, signal type, and places needing attention or protection, but also the overall density of device layout should be considered to make the density uniform

5) Which the components that need to be replaced frequently can be easily replaced, and whether the PCB is easy to insert into the device The convenience and reliability of replacing and connecting frequently replaced parts shall be ensured