Thermal Design Guide for High Power PCB Board

If you are using power electronic equipment PCB, embedded system, industrial equipment, or designing a new motherboard, you must deal with the rising temperature in the system Continuous high temperature operation will shorten the life of the circuit board, and may even lead to the failure of some key points in the system Early consideration of heat dissipation in the design process will help extend the life of circuit boards and components Thermal design starts from estimating the operating temperature, considering the operating temperature of the circuit board, the operating environment of the board, and the power consumption of the components These factors together determine the operating temperature of the circuit board and components This will also help customize the cooling strategy Placing the circuit board in an environment with higher ambient temperature can keep more heat, so it will operate at higher temperature

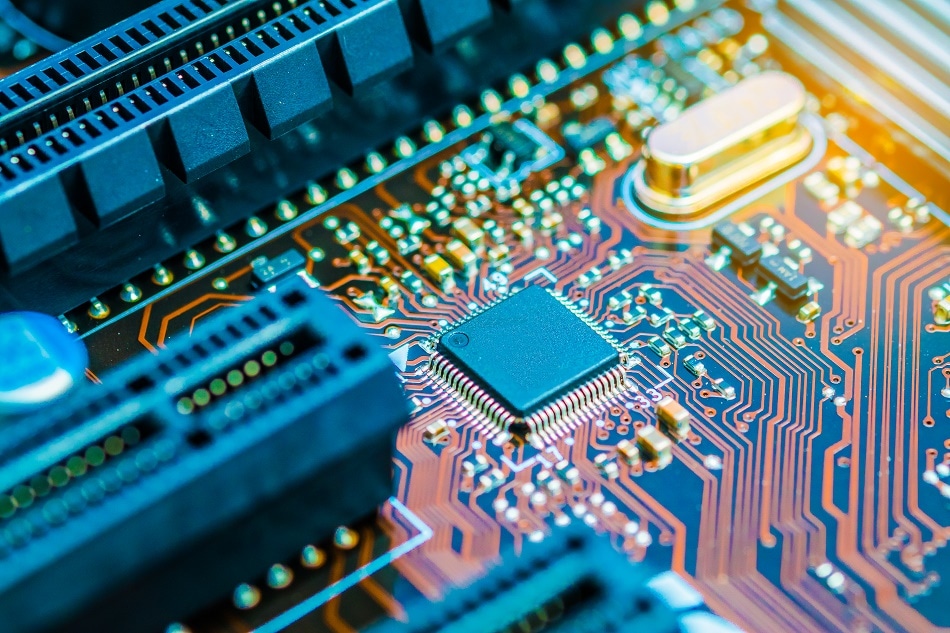

PCB board

Components with high power consumption will require more efficient cooling methods to maintain the temperature at the set level. Important industry standards may specify the temperature of components and substrates during operation. Before designing the thermal management strategy, make sure to check the allowable operating temperature of the components in the data sheet and the temperature specified in the important industry standards. Active and passive cooling needs to be combined with an appropriate board layout to prevent damage to the board.

However, the evaporative cooling module is very bulky, which is not suitable for many systems. If the system leaks or breaks, the entire circuit board will leak liquid. In this case, active cooling can be used to provide the same or better cooling.

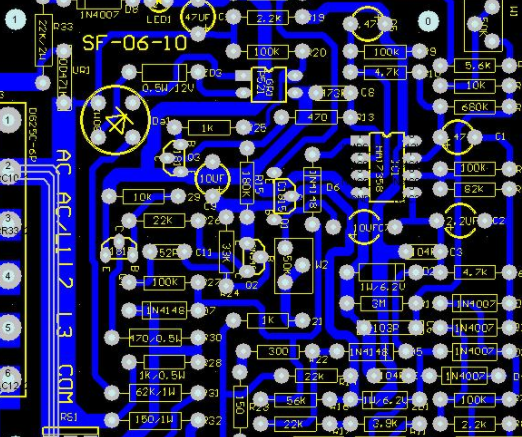

Then, the heat generated in the surface trace is easily dissipated to the ground level Carrying traces of high current, especially in DC circuits, requires more copper weight to dissipate heat on the circuit board This may require a wider trajectory than that commonly used in high-speed or high-frequency equipment The geometry affects the tracking impedance of the AC signal, which means you may need to change the stack to match the impedance to the value defined in the signal standard or source/load the component Pay attention to the thermal cycling in the circuit board, because repeated temperature cycling between high and low values will lead to stress accumulation in vias and traces This may cause tube breakage in high aspect ratio vias Long time loop back will also lead to trace delamination on the surface layer, which may damage the PCB

The above is the explanation given by the editor of pcb circuit board company. If you want to know more about PCBA, you can go to our company's home page to learn about it. In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.