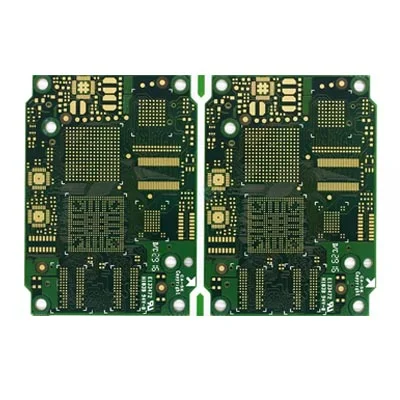

Ten-layer HDI Impedance Control Automotive Digital PCB

Name: Ten-layer HDI Impedance Control Automotive Digital PCB

Substrate: FR-4

Copper Thickness: 1 oz

Plate thickness: 1.6MM

Surface Treatment: Immersion Gold 45%

Board size: 90.10*102.11MM/2PCS

Material: FR-4

Plate thickness: 1.6MM

Number of floors: 10L1/H/H/H/H/H/H/H/H/1OZ

Single chip size: 49.93*70.07MM

Connection size: 90.10*102.11MM/2PCS

Surface Technology: Immersion Gold 45%

Pore Density: 360,000

Line width and distance: 0.075/0.075MM

Solder Mask: Green

Why do PCB do impedance

1. Check the table line to consider the installation of electronic components, and consider conductive performance and other issues after insertion. Therefore, the lower the impedance, the better the resistance.

2. PCB line boards must go through process production links such as copper, electroplating tin, and connecting welding. The materials used in these links must ensure that the resistivity is low to ensure that the overall impedance of the line board can reach the product quality requirements. , Can run normally

3. The tin plating of the PCB circuit board is the most prone problem in the production of the entire line board, and it is a key link that affects impedance. The biggest defect of the chemical tin plating layer is that it is easy to change and poor tin properties, which will cause the lineboard to be difficult to weld, excessive impedance causes poor conductive performance or unstable rectification performance.

4. There will be various signals transmission in the conductor in the PCB line board. When the transmission rate is increased, the frequency must be increased. If the line itself is different due to erosion, stacking thickness, and wire width, it will cause changes in impedance value changes. In distortion of its signal, resulting in decline in the performance of the line board, so the control value is needed to be within a certain range

Name: Ten-layer HDI Impedance Control Automotive Digital PCB

Substrate: FR-4

Copper Thickness: 1 oz

Plate thickness: 1.6MM

Surface Treatment: Immersion Gold 45%

Board size: 90.10*102.11MM/2PCS

Material: FR-4

Plate thickness: 1.6MM

Number of floors: 10L1/H/H/H/H/H/H/H/H/1OZ

Single chip size: 49.93*70.07MM

Connection size: 90.10*102.11MM/2PCS

Surface Technology: Immersion Gold 45%

Pore Density: 360,000

Line width and distance: 0.075/0.075MM

Solder Mask: Green