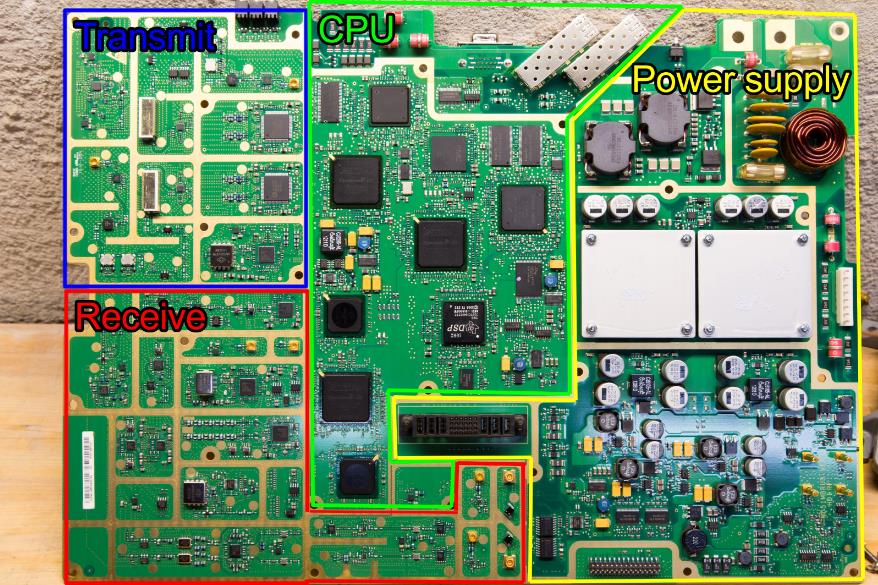

Huawei RRU3908 base station PCB Assembly

Name: Huawei RRU3908 base station PCB Assembly

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI AutomatIC Optical Tester, ICT Tester, BGA Rework Station

Placement speed: chip component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products

The Huawei RRU3908 is an outdoor Radio Base Station with one to four carriers and one to six sectors at 20/40 Watt RF output power per carrier.

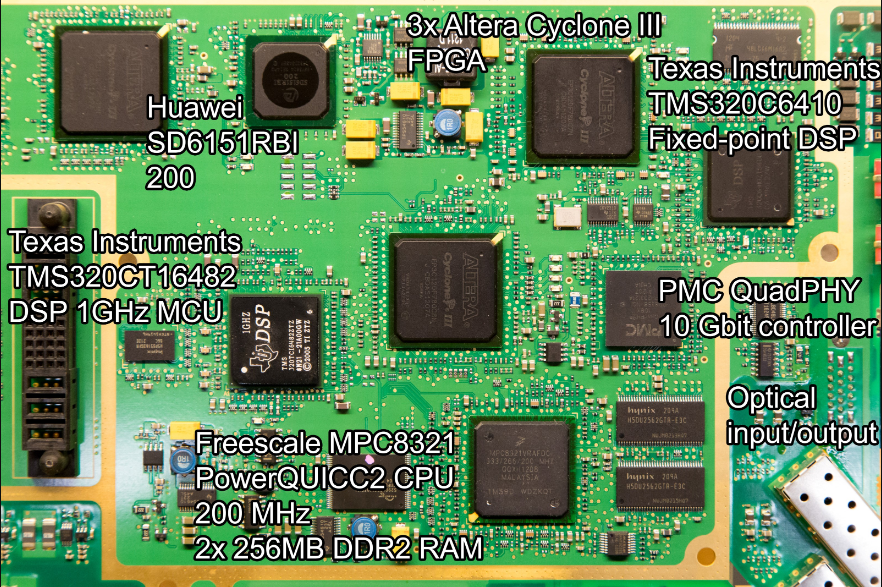

Central Processing Units

Network communication is handled by a Freescale MPC8321 PowerQUICC2 CPU which runs at 200 MHz and has 2x 256 MB Hynix DDR2 RAM. It utilises a PMC QuadPHY 10 GB controller for the two optical input / output.

Decoding and encoding of the single bit streams for ADC and DAC are handled by the 3 Altera Cyclone III FPGA and the custom Huawei SD6151RBI controllers.

The single bit streams are treated by the Texas Instrument TMS320 series DSP CPUs. TMS320C6410 which is a fixed-point DSP that only calculates with integer numbers and the TMS320CT16482 1 GHz DSP CPU calculates floating point numbers.

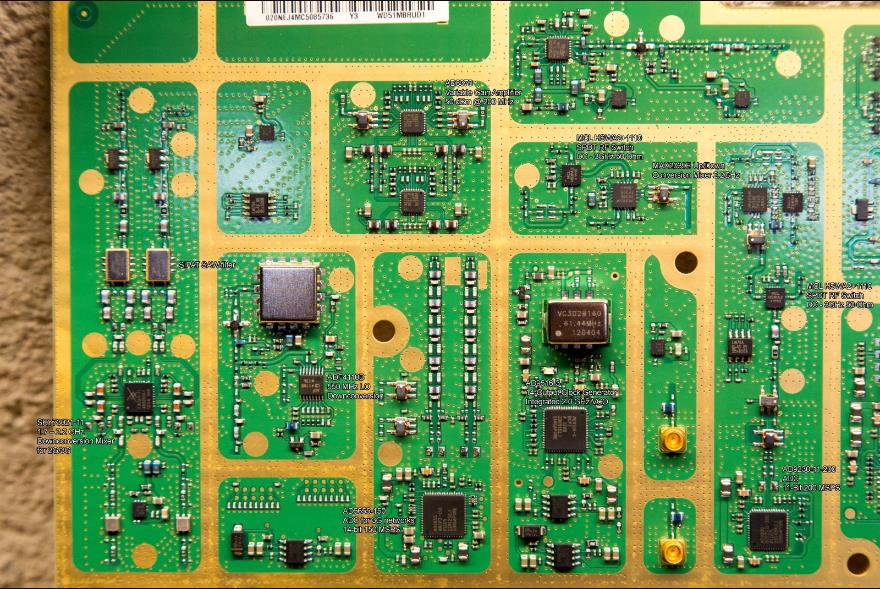

Receive part

The input signal comes in two out of phase lines and are first treated by a Skyworks SKY73021-11 1.7 to 2.2 GHz downconversion mixer to get the frequency from 2.2 GHz to 550 MHz.

The local oscillator for the downconversion mixer is a Analog Devices ADF4110B.

A SIPAT SAW filter is used for isolation.

Depending on signal origin or type, I assume that the Analog Devices AD8376 Variable Gain Amplifiers are used before the signal lines split out into either a 3G ADC line or 4G ADC line.

The 3G line analog to digital conversion is handled by the Analog Devices AD6655-10 which is a 14-bit 150 MSPS chip that is specifically targeted for the 3G base stations.

The 4G line has a few more components as there is 2 MCL HSWA+1110 SPDT RF switch that feeds into 2 Maxim MAX2039E up/dowoconversion mixer and through a additional MCL HSWA+1110 SPDT RF switch it is handled by the Analog Devices AD9230-11-200 ADC which is a 11-bit 200 MSPS chip.

All timing is handled by the Analog devices AD9516-3 which is a 14-output clock generator with a built in 2 GHz local oscillator.

Transmit part

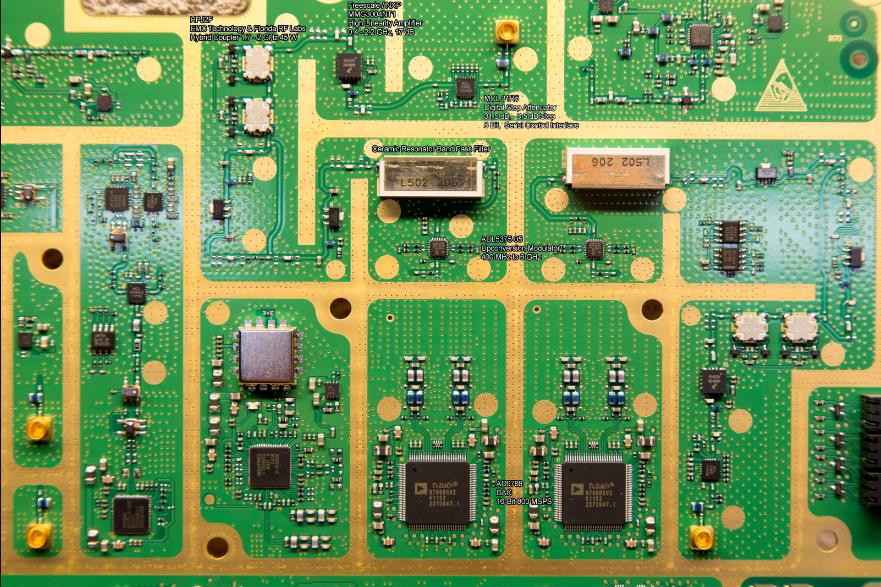

The single bit datastream from the Altera Cyclone III FPGA is handled by 2 Analog Devices TxDAC AD9788 which are specified for 16-bit 800 MSPS.

To get the signal up in frequency to the broadcast carrier frequency 2 Analog Devices ADL5375-05 upconversion modulators are used. These has a range from 400 MHz to 6 GHz.

The signal is then sent through a 5 staged ceramic resonator band pass filter.

Signal phase can be switched from the setup of transistors and EMC Technology & Florida RF Labs HPJ2F hybrid couplers.

The pre-amplifier before the signal is sent to the power amplifier is a Freescale MMG3004NT1 high linearity amplifier capable of 17 dB amplification in the range of 400 MHz to 2.2 GHz.

To control the signal strength a MCL 31R5 digital step attenuator sits before the output connector. This is a 31.5 dB attenuator that can work in 0.5 dB steps from a 6-bit serial control interface.

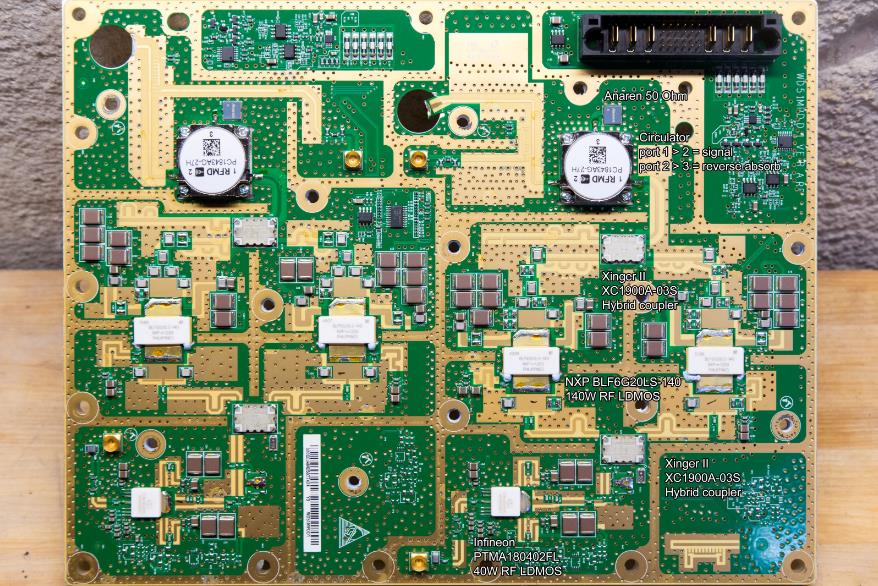

Power Amplifier

The power amplifier uses two stages where the first is a Infineon PTMA180402FL 40 Watt RF LDMOS that through a Xinger II XC1900A-03S hybrid coupler feeds two 90 degree out of phase signals to the output stage transistors which are NXP BLF6G20LS-140 140 Watt RF LDMOS.

The output is recombined in a Xinger II XC1900A-03S hybrid coupler before leaving to the diplexer through a circulator.

Kingford supports Huawei RRU3908 base station PCB Assembly business, we are a professional PCBA one-stop assembly factory, welcome to place an order.

Name: Huawei RRU3908 base station PCB Assembly

Number of SMT lines: 7 high-speed SMT patch supporting production lines

SMT daily production capacity: more than 30 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI AutomatIC Optical Tester, ICT Tester, BGA Rework Station

Placement speed: chip component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, and the pin spacing can reach ±0.04mm

IC type patch accuracy: it has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. Can be mounted/inserted/mixed TFT display driver board, mobile phone motherboard, battery protection circuit and other difficult products