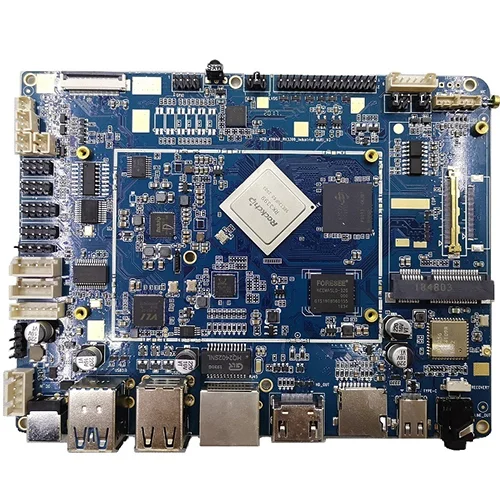

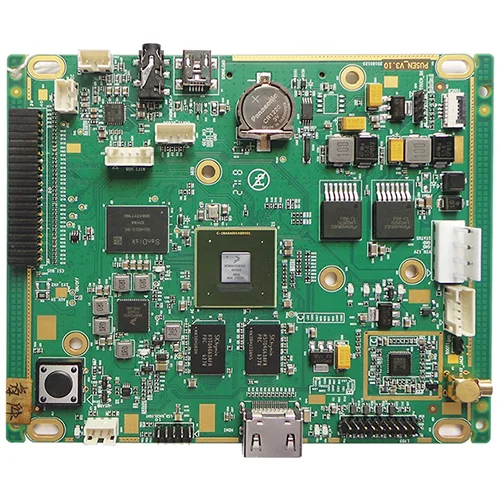

Mass touch screen motherboard assembly

Name: Mass touch screen motherboard assembly

Substrate: FR-4/High TG/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea

Touch screen, also known as "touch screen" or "touch panel", is an inductive liquid crystal display device that can receive input signals such as contacts. The tactile feedback system can drive various connecting devices according to the pre-programmed program, which can be used to replace the mechanical button panel, and create vivid audio-visual effects through the liquid crystal display screen. As the latest computer input device, the touch screen is currently the simplest, most convenient and natural way of human-computer interaction. It endows multimedia with a new look and is a very attractive new multimedia interactive device. No need to learn, everyone can use it, which is the biggest magic power of the touch screen, which cannot be compared with the keyboard or mouse. Touch-screen is mainly used in the inquiry of public information, leadership office, industrial control, military command, electronic game, ordering songs and dishes, multimedia teaching, real estate pre-sale and so on.

Basic concept

The so-called touch screen, from the market concept, is a computer input device that everyone can use, or a device that everyone can use to communicate with a computer. No need to learn, everyone can use it, which is the biggest magic power of the touch screen, which cannot be compared with the keyboard or mouse. Everyone can use it, which marks the real arrival of the era of popularization of computer applications. This is also the reason for developing touch screens, developing KIOSKs, developing KIOSK networks, and striving to form a Chinese touch industry.

From the perspective of technical principles, the touch screen is a set of transparent absolute positioning system. The main feature is that it must be transparent first, so it must solve the transparency problem through material technology, such as digitizers, writing boards, and elevator switches. It is not a touch screen; secondly, it is an absolute coordinate, where you touch with your finger, no second action is needed, unlike a mouse, which is a system of relative positioning, we can notice that the touch screen software does not need a cursor, and the cursor will affect it.

For relative positioning equipment, to move to a place, you must first know where you are now and which direction to go, and you need to keep giving the user feedback on the current position at all times so that there will be no deviation. These are not needed for the touch screen that adopts absolute coordinate positioning; the second is to be able to detect the touch action of the finger and judge the position of the finger.

The first feature of the touch screen:

Transparent, it directly affects the visual effect of the touch screen.

Transparency has a degree of transparency. Infrared technology touch screens and surface acoustic wave touch screens are only separated by a layer of pure glass. A general concept, many touch screens are multi-layer composite films, and it is not enough to summarize its visual effect with a little transparency. It should include at least four characteristics: transparency, color distortion, reflectivity and clarity, and can be reproduced. For example, the degree of reflection includes the degree of specular reflection and the degree of diffraction reflection, but the diffraction reflection on the surface of the touch screen has not yet reached the level of the CD disk. For users, these four metrics are basically enough.

Due to the existence of light transmittance and wavelength curves, the image seen through the touch screen will inevitably have color distortion with the original image. The static image is just a color distortion, and the dynamic multimedia image is not very good. Comfortable, the color distortion is the maximum color distortion in the picture, naturally the smaller the better. The usual transparency can only be the average transparency in the picture, of course, the higher the better.

Reflectiveness mainly refers to the light and shadow behind the overlapping images caused by specular reflection, such as human shadows, windows, lights, etc. Reflection is a negative effect brought by the touch screen. The smaller the better, it affects the user's browsing speed, and even the image characters cannot be recognized in serious cases. The use environment of the highly reflective touch screen is limited, and the lighting arrangement on site is also forced to be adjusted. Most touch screens with reflection problems provide another type of surface treatment: matte surface touch screen, also called anti-glare type, the price is slightly higher, anti-glare type has significantly reduced reflection, suitable for halls or exhibitions with sufficient lighting However, the light transmittance and clarity of the anti-glare type will also be greatly reduced. Clarity, after some touch screens are installed, the handwriting is blurred, the details of the image are blurred, the whole screen appears blurred, and it is difficult to see clearly, which means that the clarity is too poor. The problem of clarity is mainly caused by the touch screen with multi-layer film structure, which is caused by repeated reflection and refraction of light between the film layers. In addition, the anti-glare touch screen also reduces the clarity due to surface frosting. The clarity is not good, the eyes are prone to fatigue, and it will also cause some damage to the eyes. When purchasing a touch screen, pay attention to discrimination.

The second feature of the touch screen:

The touch screen is an absolute coordinate system, and you can directly click on it if you want to choose. The essential difference from relative positioning systems such as the mouse is the intuitiveness of one-time positioning. The characteristic of the absolute coordinate system is that each positioning coordinate has nothing to do with the previous positioning coordinates. The touch screen is physically an independent coordinate positioning system. The data of each touch is converted into coordinates on the screen through calibration data. In this way, it is required No matter what the coordinates of the touch screen are, the output data of the same point is stable. If it is unstable, then the touch screen cannot guarantee absolute coordinate positioning, and the point is inaccurate. This is the most feared problem of the touch screen: drift. In terms of technical principles, any touch screen that cannot guarantee the same sampling data for each touch at the same point will inevitably drift. At present, only capacitive touch screens have drift.

The third feature of the touch screen:

To detect touch and locate, various touch screen technologies rely on their own sensors to work, and some touch screens even have a set of sensors themselves. The respective positioning principles and the sensors used determine the response speed, reliability, stability and life of the touch screen.

Development application

With the increasing number of multimedia information query devices, people are talking about touch screens more and more, because touch screens are not only suitable for the national conditions of China's multimedia information query, but also have many advantages such as durability, fast response, space saving, and easy communication. With this technology, the user can operate the host computer by lightly touching the icons or text on the computer display screen with his fingers, thus making the human-computer interaction more straightforward. This technology greatly facilitates those who do not understand computer operation. user.

Touch-screen is boundless in the range of application of my country, mainly contains the inquiry of public information; As the service inquiry of departments such as telecommunication bureau, the tax bureau, bank, electric power; Electronic games, ordering songs and dishes, multimedia teaching, real estate pre-sales, etc. In the future, touch screens will also enter the family.

With the increasing use of computers as information sources, touch screens are easy to use, durable, fast in response, space-saving and other advantages, making system designers more and more feel that using touch screens does have considerable advantages. It has only been a few years since the touch screen appeared in the Chinese market. This new multimedia device has not been contacted and understood by many people, including some system designers who are planning to use the touch screen, and they all regard the touch screen as dispensable. From the perspective of the popularity of touch screens in developed countries and the stage that my country's multimedia information industry is in, this concept is still universal. In fact, the touch screen is a device that makes multimedia information or control a new look. It gives a new look to the multimedia system and is a very attractive new multimedia interactive device. The system designers in developed countries and the system designers in our country who took the lead in using touch screens already know clearly that touch screens are no longer dispensable for computers in various application fields, but indispensable equipment. It greatly simplifies the use of computers, even people who know nothing about computers can still use them at their fingertips, making computers more attractive. It solves the problems that cannot be solved by computers in the public information market.

Main type

To distinguish touch screens from the technical principles, they can be divided into five basic types: vector pressure sensing technology touch screens, resistive technology touch screens, capacitive technology touch screens, infrared technology touch screens, and surface acoustic wave technology touch screens. Among them, the vector pressure sensing technology touch screen has withdrawn from the stage of history; the infrared technology touch screen is cheap, but its outer frame is fragile, prone to light interference, and distortion in the case of a curved surface; the capacitive technology touch screen design concept is reasonable, but its image distortion problem is difficult to get Fundamentally solved; resistive technology touch screen positioning is accurate, but its price is high, and it is afraid of scratches and damage; surface acoustic wave touch screen solves various defects of previous touch screens, clear and not easy to be damaged, suitable for various occasions, the disadvantage is that the screen surface If there are water droplets and dust, the touch screen will become dull or even not work.

According to the working principle of the touch screen and the medium for transmitting information, the touch screen is divided into four types, which are resistive, capacitive, infrared, and surface acoustic wave. Each type of touch screen has its own advantages and disadvantages. To know which touch screen is suitable for which occasion, the key is to understand the working principle and characteristics of each type of touch screen technology. The following is a brief introduction to the various types of touch screens mentioned above:

Four-wire resistive screen

When the two transparent metal layers of the four-wire resistance analog technology work, each layer increases a constant voltage of 5V: one vertical direction,

a horizontal direction. A total of four cables are required. Features: High resolution, high-speed transmission response. Surface hardness treatment to reduce scratches, scratches and anti-chemical treatment. With smooth and matte treatment. One calibration, high stability, never drift.

Five-wire resistive screen

The base layer of the five-wire resistance technology touch screen adds voltage fields in two directions to the conductive working surface of the glass through a precision resistance network. We can simply understand that the voltage fields in two directions are applied to the same working surface in time-sharing. The outer nickel-gold conductive layer is only used as a pure conductor, and the position of the touch point can be measured by time-sharing detection of the X-axis and Y-axis voltage values of the inner ITO contact point after touching. The inner layer ITO of the five-wire resistive touch screen needs four leads, and the outer layer is only used as a conductor, and the touch screen has a total of 5 lead wires.

Features: High resolution, high-speed transmission response. High surface hardness to reduce scratches, scratches and anti-chemical treatment. It can still be used after 30 million contacts at the same point. Conductive glass is the medium of the substrate. One calibration, high stability, never drift. The five-wire resistive touch screen has the disadvantages of high price and high environmental requirements.

Resistive touch screen

This touchscreen uses pressure sensitivity for control. The main part of the resistive touch screen is a resistive film screen that fits well with the surface of the display. This is a multi-layer composite film. Resistor) Conductive layer, covered with an outer surface hardened, smooth and scratch-resistant plastic layer, its inner surface is also coated with a layer, and there are many small (less than 1/1000 inch) transparent gaps between them The isolation point separates and insulates the two conductive layers. When a finger touches the screen, the two conductive layers are in contact at the touch point, the resistance changes, and signals are generated in the X and Y directions, and then sent to the touch screen controller. The controller detects this contact and calculates the (X,Y) position, which then behaves like a simulated mouse. This is the most basic principle of resistive technology touch screen. So resistive touch screens can be operated with harder objects. The key to resistive touch screens lies in material technology. Commonly used transparent conductive coating materials are:

ITO, indium oxide, has a light transmittance of 80%, and the light transmittance decreases when it is thinner, and rises to 80% when it reaches a thickness of 300 angstroms. ITO is the main material used in all resistive technology touch screens and capacitive technology touch screens. In fact, the working surface of resistive and capacitive technology touch screens is ITO coating.

Nickel-gold coating, the outer conductive layer of the five-wire resistive touch screen is made of nickel-gold coating material with good ductility. Due to frequent touches on the outer conductive layer, the purpose of using nickel-gold material with good ductility is to prolong the service life. The cost is relatively high. Although the nickel-gold conductive layer has good ductility, it can only be used as a transparent conductor. It is not suitable as a working surface of a resistive touch screen because of its high conductivity, and the metal is not easy to achieve a very uniform thickness. It is not suitable for a voltage distribution layer and can only be used as a probe. Floor.

Limitations of resistive screens

Whether it is a four-wire resistive touch screen or a five-wire resistive touch screen, they are a completely isolated working environment from the outside world, not afraid of dust and water vapor, it can be touched by any object, can be used to write and draw, and is more suitable for the field of industrial control And the use of limited people in the office. The common disadvantage of resistive touch screens is that because the outer layer of the composite film is made of plastic material, people who don't know it may scratch the entire touch screen and cause it to be scrapped if they touch it too hard or use a sharp object. However, within the limit, the scratch will only hurt the outer conductive layer, and the scratch of the outer conductive layer has nothing to do with the five-wire resistive touch screen, but it is fatal to the four-wire resistive touch screen.

Features

1. They are all working environments that are completely isolated from the outside world, not afraid of dust, water vapor and oil pollution;

2. It can be touched with any object, and can be used to write and draw, which is their biggest advantage;

3. The accuracy of the resistive touch screen only depends on the accuracy of A/D conversion, so it can easily reach 4096*4096. In comparison, the five-wire resistance is superior to the four-wire resistance in terms of resolution accuracy, but the cost is high , so the price is very high.

Capacitive touch screen

1. Touch screen with capacitive technology

It works by using the current induction of the human body. The capacitive touch screen is a four-layer composite glass screen. The inner surface and the interlayer of the glass screen are coated with a layer of ITO, and the outermost layer is a thin layer of silica glass protective layer. The interlayer ITO coating is used as the working surface. Four electrodes, the inner ITO is the shielding layer to ensure a good working environment. When a finger touches the metal layer, due to the electric field of the human body, a coupling capacitance is formed between the user and the surface of the touch screen. For high-frequency currents, the capacitance is a direct conductor, so the finger absorbs a small current from the contact point. This current flows from the electrodes on the four corners of the touch screen, and the current flowing through these four electrodes is proportional to the distance from the finger to the four corners. The controller obtains the position of the touch point through accurate calculation of the four current ratios. .

2. Defects of capacitive touch screen

The light transmittance and clarity of the capacitive touch screen is better than that of the four-wire resistive screen, but of course it cannot be compared with the surface acoustic wave screen and the five-wire resistive screen. The capacitive screen is seriously reflective, and the four-layer composite touch screen with capacitive technology has uneven light transmittance for each wavelength of light, and there is a problem of color distortion. Due to the reflection of light between layers, image characters are also blurred. In principle, the capacitive screen uses the human body as an electrode of a capacitor element. When a conductor is close to the interlayer ITO working surface and couples a sufficient amount of capacitance, the current flowing away is enough to cause the malfunction of the capacitive screen. . We know that although the capacitance value is inversely proportional to the distance between electrodes, it is directly proportional to the relative area, and is also related to the dielectric coefficient of the medium. Therefore, when a large area of the palm or a hand-held conductor is close to the capacitive screen instead of touching it, it can cause the malfunction of the capacitive screen. Within 15 cm of the display or the body is close to the display, it can cause the malfunction of the capacitive screen. Another disadvantage of capacitive screens is that they do not respond when touched with gloved hands or holding non-conductive objects, because of the addition of a more insulating medium. The main disadvantage of the capacitive screen is drift: when the ambient temperature and humidity change, the environmental electric field changes, which will cause the capacitive screen to drift, resulting in inaccuracy. For example, when the temperature of the display rises after powering on, it will cause drift: when the user touches the screen while the other hand or the side of the body is close to the display, it will drift; if a large object near the capacitive touch screen is moved, it will drift back, and if someone looks around when touching the screen, it will also drift. Cause drift; the reason for the drift of the capacitive screen is the inherent technical deficiency. Although the environmental potential surface (including the user's body) is far away from the capacitive touch screen, it is much larger than the area of the finger, and they directly affect the determination of the touch position. In addition, many relationships that should be linear in theory are actually nonlinear. For example, people with different body weights or different degrees of finger wetness absorb different total currents, and the changes in the total current and the changes in the four partial currents It is a non-linear relationship. The custom polar coordinate system with four corners adopted by the capacitive touch screen has no origin on the coordinates, and the controller cannot detect and recover after the drift. Moreover, after the completion of the four A/Ds, the four points The calculation process from the flow value to the X and Y coordinate values of the touch point on the Cartesian coordinate system is complicated. Since there is no origin, the drift of the capacitive screen is cumulative, and calibration is often required on the job site. The outermost silica protective glass of the capacitive touch screen is very scratch-resistant, but it is afraid of being knocked by nails or hard objects. If a small hole is knocked out, the interlayer ITO will be damaged, whether it is the interlayer ITO or the damage during installation and transportation. The ITO layer on the inner surface, the capacitive screen will not work properly.

Piezo touch screen

Resistive touch is simple in design and low in cost, but resistive touch is limited by its physical limitations, such as low light transmittance, high line count and large detection area, which will cause a burden on the processor, and its application characteristics make it easy to age and affect service life. Capacitive touch supports multi-touch function, has higher light transmittance, lower overall power consumption, its contact surface has high hardness, no need to press, and has a long service life, but the accuracy is not enough, and it does not support stylus control . So the piezoelectric touch screen was derived.

Piezoelectric touch technology is between resistive and capacitive touch technology. The touch screen of the piezoelectric sensor supports multi-touch like the capacitive touch screen, and supports any object touch, unlike the capacitive touch screen which only supports skin-like material touch. In this way, the piezoelectric touch screen can simultaneously have the multi-touch touch of a capacitive screen and the precision of a resistive screen.

The piezoelectric touch is closer to the capacitive touch in terms of power consumption characteristics, that is, there is no power consumption when there is no touch action, while the resistive touch always consumes power. In terms of interface support, piezoelectric touch also supports serial ports, I2C and USB interfaces. From the perspective of process cost, the conversion of resistive touch control process to piezoelectric touch control process requires changing the production line equipment, and compared with the process of capacitive ITO and mask, the cost of piezoelectric touch control process is about 80%. Between -90%.

The working principle of the piezoelectric touch screen is equivalent to that of TFT. The manufacturing process part is like a capacitive touch screen, and the physical structure is like a resistive touch screen. It is a combination of three mature technologies. Therefore, the piezoelectric touch screen using new technology integrates and enhances the advantages of resistive and capacitive, and avoids the shortcomings of both. Piezoelectric touch screen is generally multi-layer composite film of hard plastic plate (or plexiglass) substrate, hard plastic plate (or plexiglass) as the base layer, the surface is coated with a transparent conductive layer, and then covered with a layer of hardened outer surface , Smooth scratch-resistant plastic layer, its surface is also coated with a transparent conductive layer, there are many small transparent isolation points between the two conductive layers. The transmittance of the screen is slightly lower than that of glass.

The representative of the piezoelectric touch screen is the smart device Ten (namely T10), the piezoelectric IPS hard screen, which almost reaches the same level of display effect and touch experience as the iPad, and at the same time, the cost is lower and the performance is very good.

Infrared touch screen

In the early conception, infrared touch screens had technical limitations such as low resolution, limited touch methods, and susceptibility to environmental interference and misoperation, so they once faded out of the market. Since then, the second-generation infrared screen has partially solved the problem of anti-light interference, and the third and fourth generations have also improved in terms of resolution and stability, but none of them has made a qualitative leap in key indicators or overall performance. However, anyone who understands touch screen technology knows that infrared touch screens are not affected by current, voltage and static electricity, and are suitable for harsh environmental conditions. Infrared technology is the ultimate development trend of touch screen products. Touch screens using acoustics and other material science technologies have their insurmountable barriers, such as damage and aging of a single sensor, fear of contamination of the touch interface, destructive use, and complicated maintenance. As long as the infrared touch screen truly achieves high stability and high resolution, it will replace other technical products and become the mainstream of the touch screen market.

In the past, the resolution of the infrared touch screen was determined by the number of infrared tubes in the frame, so the resolution was low. The main domestic products on the market were 32x32 and 40X32. In addition, it is said that the infrared screen is sensitive to the factors of the lighting environment. When it is large, it will misjudge or even crash. These are the weaknesses of the infrared screens promoted by domestic agents of foreign non-infrared touch screens. The resolution of the latest technology fifth-generation infrared screen depends on the number of infrared tubes, scanning frequency and difference algorithm. The resolution has reached 1000X720. At the beginning, the weakness of anti-light interference has been better overcome.

The fifth-generation infrared touch screen is a new generation of intelligent technology products. It realizes 1000*720 high resolution, multi-level self-adjustment and self-recovery hardware adaptability and highly intelligent discrimination and identification, and can be used in various harsh environments for a long time. Use it arbitrarily. And it can customize extended functions for users, such as network control, sound sensing, human body proximity sensing, user software encryption protection, infrared data transmission, etc. The other main disadvantage of the infrared touch screen advertised by the media is its poor anti-riot performance. In fact, the infrared screen can use any anti-riot glass that customers think is satisfactory without increasing too much cost and affecting performance. This is something that other touch screens cannot follow.

Surface Acoustic Wave Touch Screen

1. Surface acoustic waves

Surface acoustic wave, a type of ultrasonic wave, is a mechanical energy wave that propagates shallowly on the surface of a medium (such as rigid materials such as glass or metal). Through the wedge-shaped triangular base (strictly designed according to the wavelength of the surface wave), directional and small-angle surface acoustic wave energy emission can be achieved. The performance of surface acoustic wave is stable, easy to analyze, and has very sharp frequency characteristics in the process of shear wave transmission. Conductive materials, detection technology and other technologies are quite mature. The touch screen part of a surface acoustic wave touch screen can be a flat, spherical or cylindrical glass plate installed in front of a CRT, LED, LCD or plasma display screen. The upper left corner and the lower right corner of the glass screen are respectively fixed with vertical and horizontal ultrasonic transmitting transducers, and the upper right corner is fixed with two corresponding ultrasonic receiving transducers. The four perimeters of the glass screen are engraved with reflective stripes at a 45° angle from sparse to dense.

2. Working principle of surface acoustic wave touch screen

Take the X-axis transmitting transducer in the lower right corner as an example: the transmitting transducer converts the electrical signal sent by the controller through the touch screen cable into sound wave energy and transmits it to the left surface, and then a set of precise reflection stripes under the glass plate Reflect the sound wave energy into an upward uniform surface, the sound wave energy passes through the surface of the screen, and then gathers the reflection stripes on the upper side into a right line and propagates to the X-axis receiving transducer, and the receiving transducer will return the surface acoustic wave The energy becomes an electrical signal.

When the transmitting transducer emits a narrow pulse, the sound wave energy reaches the receiving transducer through different paths, the rightmost one arrives the earliest, the leftmost one arrives the latest, and the early and late arrivals are superimposed into one Wider waveform signal, it is not difficult to see that the received signal gathers all the sound wave energy returning through different paths in the X-axis direction, and they travel the same distance on the Y-axis, but on the X-axis, the farthest than The closest one has gone twice as far as the maximum distance on the X axis. Therefore, the time axis of this waveform signal reflects the position of each original waveform before being superimposed, that is, the X-axis coordinate.

When there is no touch between the transmitted signal and the received signal waveform, the received signal waveform is exactly the same as the reference waveform. When a finger or other object that can absorb or block sound wave energy touches the screen, the sound wave energy that goes upward on the X-axis through the finger is partially absorbed, reflecting an attenuation gap on the received waveform, that is, at a certain moment in the waveform. The received waveform corresponds to a gap in the signal attenuation of the part blocked by the finger, and the position of the gap is calculated to obtain the touch coordinates. The controller analyzes the attenuation of the received signal and determines the X coordinate from the position of the gap. After that, the same process of the Y axis determines the Y coordinate of the touch point. In addition to the X and Y coordinates that general touch screens can respond to, the surface acoustic wave touch screen also responds to the third axis Z-axis coordinates, that is, it can sense the value of the user's touch pressure. The principle is calculated by the attenuation at the attenuation of the received signal. Once the three axes are determined, the controller will pass them to the host.

3. Features of surface acoustic wave touch screen

High definition, good light transmittance. Highly durable, good scratch resistance (relative to resistors, capacitors, etc. have surface film). Responsive. Not affected by environmental factors such as temperature and humidity, high resolution, long life (50 million times under good maintenance); high light transmittance (92%), can maintain clear and bright image quality; no drift, only need to install One correction; there is a third axis (ie, pressure axis) response, which is currently used more in public places. The surface acoustic wave screen needs frequent maintenance, because dust, oil or even beverage liquid stains on the surface of the screen will block the waveguide groove on the surface of the touch screen, so that the wave cannot be launched normally, or the waveform will change and the controller cannot be recognized normally, thus affecting For the normal use of the touch screen, users must strictly pay attention to environmental hygiene. The surface of the screen must be wiped frequently to keep the screen clean, and it should be wiped off completely and thoroughly on a regular basis.

4. Surface Acoustic Wave Touch Screen FAQ

① The surface acoustic wave screen is not allowed to touch

Please run the touch screen calibration program. (Start--Settings--Control Panel--Sonic Screen Icon--Caliberate button).

If it is a newly purchased touch screen, please try to delete the driver, then power off the host for 5 seconds and turn it on to reinstall the driver.

If the above method does not work, it may be that the reflection stripes of the acoustic wave screen have been slightly damaged during transportation and cannot be completely repaired.

If the acoustic screen is inaccurate after using for a period of time, it may be the reflection stripes around the screen or the transducer is covered by dust. If you are using our company's LT series models, you need to open the door behind the monitor behind the cabinet. Loosen the left and right four nuts that fix the display and the bolts on the front top of the display, and check that the gap between the front display and the front panel of the cabinet is sufficient, or remove the display and place it on a foam or soft cushion, and then use a soft Spray the cloth with computer cleaner and wipe around the screen.

There are water droplets or other soft things sticking to the surface of the touch screen. The touch screen misjudged that there was a hand touch, which caused the surface acoustic wave screen to be inaccurate. Just wipe it off.

② The surface acoustic wave screen cannot be calibrated

If you are using a branded machine, the MOUSE driver can be pre-installed in some branded machines, which will conflict with the touch screen driver, just uninstall it.

It is possible that the touch screen control card receives an operation signal before the host starts to load the touch screen driver, please power off and restart the computer and recalibrate.

It may be that the touch screen driver is installed abnormally, please delete the driver and reinstall it (Control Panel/Add and Remove Programs).

It may be that after the acoustic wave screen has been used for a period of time, the reflective stripes around the screen are covered by a large amount of dust, which makes it impossible to calibrate or the position of the touch screen is inaccurate. You need to dismantle the display components and hand them over to the dealer under the guidance of our technical staff. The dealer cleans the screen.

③ The surface acoustic wave screen does not respond to touch

It may be that among the cables of the touch screen, one of the cables connected to the keyboard port of the host computer (5V touch screen operating voltage is taken from the keyboard port) is not connected, please check the connection.

It may be that the serial port number selected during the driver installation process of the touch screen does not correspond to the serial port number actually connected to the touch screen. Please uninstall the driver and reinstall it.

It may be that the host is a domestic original machine, and the installed operating system is an OEM version, which has been adjusted by the manufacturer, resulting in non-standard serial communication and incompatibility with the touch screen driver. If possible, please format the hard disk and drive the touch screen after installing the system.

It may be that the touch screen driver version is too low, please install the latest driver.

Check whether there is a device in the host that conflicts with serial port resources and adjust each hardware device. For example, the default IRQ of some network cards is 3 after installation, which conflicts with the IRQ of COM2.

④ The response time of the surface acoustic wave screen is very long

There may be moving water droplets on the touch screen, and the touch screen responds to the operation of water droplets. Please wipe it with a dry soft cloth.

It may be that the grade of the host is too low and the clock frequency is too low, please replace the host.

⑤ Partial touch of the surface acoustic wave screen does not respond

It is possible that the reflective stripes on the touch screen are partially covered, please wipe it with a dry soft cloth.

It is possible that the reflective stripes on the touch screen are partially scratched off by a hard object, which cannot be repaired.

Kingford provides Mass touch screen motherboard assembly services. This is a PCBA one-stop assembly factory with senior industry experience. Welcome to inquiry.

Name: Mass touch screen motherboard assembly

Substrate: FR-4/High TG/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea