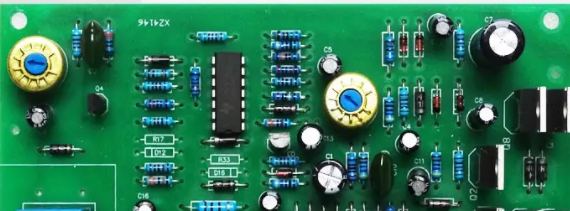

SMT (Surface Mount Technology) is a technology widely used in the manufacture of electronic products. Compared with the traditional TH (Through-Hole) plug-in processing technology, SMT SMT has the following advantages:

1. Miniaturization: SMT components are small in size and light in weight, enabling more miniaturized and lightweight product design. This is especially important for electronic devices that need to be portable and compact.

2. High integration: SMT components can be highly integrated through printed circuit boards (PCBS) to improve product functionality and performance.

3. High speed: SMT patch processing can be completed automatically, so the production speed is fast, greatly shortening the product manufacturing cycle, and improving the production efficiency.

4. Reliability: SMT patch processing is connected by welding, which is more reliable than plug-in connection. At the same time, more pin connections can be implemented on the PCB for SMT components, thus improving connection stability.

5. Low cost: SMT patch processing can realize large-scale automated production, which can effectively reduce the production cost.

Therefore, SMT patch processing plays a very important role in modern electronic product manufacturing, which can realize the advantages of miniaturization, high speed, high reliability, high integration and low cost.

2. Four methods to ensure the quality of PCBA processing

PCBA processing is a complex process that requires attention to many details to ensure processing quality. The following are four ways to ensure the quality of PCBA processing:

1. Quality Control: By implementing good quality control procedures, we can ensure that all PCBA boards can meet the expected quality standards. This can include inspection and testing at different stages, from PCB manufacturing to component procurement and assembly, where strict quality control is required.

2. Detection and testing: In the process of PCBA processing, detection and testing are essential steps. These tests can cover aspects such as component installation position and orientation, weld quality and circuit connectivity. Through these tests, potential problems can be discovered and solved in time to ensure the quality of PCBA board.

3. Use high-quality raw materials: Selecting high-quality raw materials can ensure the reliability and performance of the PCBA board. When selecting PCBS, components, welding materials and other accessories, pay attention to their quality and origin. Choosing certified suppliers can reduce potential risks and ensure the quality of PCBA boards.

4. Professional technical team: A professional technical team can ensure that every step of PCBA processing is strictly supervised and controlled. The technical team should have in-depth knowledge and experience of PCBA processing, and can provide guidance and support in the whole process to ensure the quality of PCBA board.

Shenzhen kingford own SMT processing plant, can provide minimum package 0201 components SMT processing services. The SMT plant is equipped with 3 Fuji high-speed SMT production lines, 2 DIP plug-in production lines, including AOI optical detector, automatic solder paste printing machine, semi-automatic solder paste printing machine, lead-free wave soldering, lead wave soldering, upper and lower 8 temperature zone reflow welding, PCBA functional testing frame, aging, plate loading machine, cleaning tools, etc., and a professional research and development laboratory is also set up. Five professional engineers cooperate with customers to conduct general function testing, test point testing, as well as channel, noise, waveform, drop and temperature testing.