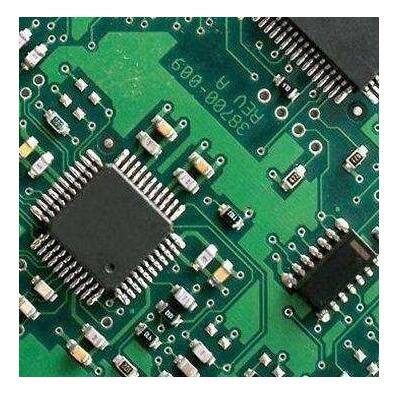

Electromagnetic compatibility (EMC) and associated electromagnetic interference (EMI) have historically been a major concern for system design engineers,These two issues are a particular headache for PCB layout and design engineers.

7 Tips to Avoid electromagnetic problems in PCB design

Tip 1: PCB grounding

An important way to reduce EMI is to design PCB connection stratum. The first step is to make the ground area within the total area of the PCB board as large as possible, which reduces emission, crosstalk and noise. Special care must be taken to connect each component to the ground site or ground formation. Failure to do so will not allow the neutralization effect of a reliable ground formation to be fully utilized.

A particularly complex PCB design has several stable voltages. Ideally, each reference voltage has its own grounding. However, too many layers will increase the manufacturing cost of PCB, so that the price is too high. A compromise is to use grounding strata at three to five different locations, each of which may contain multiple grounding sections. This not only controls the manufacturing cost of the circuit board, but also reduces EMI and EMC.

A low impedance grounding system is important if you want to minimize the EMC. In multilayer PCB, had better have a solid ground plane, rather than a copper balance block (copper thieving) or messy ground plane, because it has a low impedance, can provide current path, is the best reverse signal source.

The time it takes for the signal to return to earth is also important. The signal must travel to and from the source in the same amount of time, otherwise an antennae-like phenomenon would occur, making the radiated energy part of EMI. Similarly, the route of the current to/from the source should be as short as possible, and if the source path and the return path are not equal in length, there will be ground bounce, which will also produce EMI.

If the signal time in and out of the signal source is not synchronized, it will produce a phenomenon similar to the antenna, which radiates energy and causes EMI

Tip 2: Distinguish EMI

Since EMI is different, a good EMC design rule is to separate analog and digital circuits. Analog circuits with high amperage or high current should be kept away from high-speed wiring or switching signals. If possible, they should be protected by grounding signals. On multilayer printed circuit board, analog wiring should be on one grounding, and switch wiring or high-speed wiring should be on another grounding. As a result, signals with different characteristics are separated.

Sometimes a low pass filter can be used to eliminate the high frequency noise coupled to the surrounding lines. The filter can suppress the noise and return a steady current. It is important to separate the grounding of analog and digital signals. Because analog and digital circuits have unique characteristics, it is important to keep them separate. Digital signals shall have digital ground and analog signals shall terminate at analog ground.

In digital circuit design, experienced PCB layout and design engineers pay special attention to high speed signals and clocks. At high speeds, the signal and clock should be as short and close to the ground layer as possible because, as mentioned earlier, the ground layer keeps crosstalk, noise and radiation within a manageable range.

Digital signals should also be kept away from the power plane. If the distance is close, noise or induction can be generated, which can weaken the signal.

Tip 3: Crosstalk is the key

Wiring is especially important to ensure the proper flow of current. If the current is coming from an oscillator or other similar device, it is especially important to keep the current separate from the ground or not parallel to the other line. Two high-speed signals in parallel produce EMC and EMI, especially crosstalk. The resistance path must be shortest and the return current path as short as possible. The length of the return path should be the same as the length of the sending path.

For EMI, one is called "encroaching wire" and the other is "victimizing wire". The inductance and capacitance coupling will affect the "victimized" wire due to the presence of electromagnetic fields, thus generating forward and reverse currents on the "victimized" wire. In this way, a ripple can be generated in a stable environment where the length of the signal sent and received is almost equal.

In a well-balanced, stable wiring environment, induced currents should cancel each other out, thus eliminating crosstalk. But we live in an imperfect world, and that doesn't happen. Therefore, the goal must be to keep crosstalk at a minimum for all routes. The effect of crosstalk can be minimized if the width between parallel running lines is twice the width of the running lines. For example, if the line width is 5 mils, the minimum distance between two parallel lines should be 10 mils or greater.

PCB designers must also continue to contend with electromagnetic compatibility and interference issues as new materials and components become available.

Tip 4: Decoupling capacitor

Decoupling capacitors reduce the adverse effects of crosstalk. They should be located between the power and ground pins of the device. This ensures low AC impedance and reduces noise and crosstalk. To achieve low impedance over a wide frequency range, multiple decoupling capacitors should be used.

An important principle for placing decoupling capacitors is that the capacitors with the smallest capacitance are placed as close to the device as possible to minimize inductance effects on the wiring. This particular capacitor is as close as possible to the power pin or power line of the device and connects the capacitor pad directly to the through-hole or ground. If the cable is long, use multiple holes to minimize the grounding impedance.

Tip 5: Avoid 90° angles

To reduce EMI, avoid the 90° Angle formed by wiring, holes and other components, because the right Angle will produce radiation. At this Angle the capacitance increases and the characteristic impedance changes, resulting in reflection, which in turn causes EMI. To avoid 90° angles, route at least two 45° angles to the corner.

Tip 6: Use holes carefully

In almost all PCB layouts, holes must be used to provide conductive connections between the different layers. PCB layout engineers need to be especially careful because passing holes can create inductance and capacitance. In some cases, they also produce reflections because the characteristic impedance changes as holes are made in the wiring.

Also keep in mind that passing through the hole increases the length of the line and needs to be matched. If differential routing is used, holes should be avoided as far as possible. If this cannot be avoided, holes should be used in both routes to compensate for delays in the signal and return path.

Tip 7: Cable/physical shielding

Cables carrying digital circuits and analog currents can generate parasitic capacitors and inductors, causing many EMC related problems. If a twisted pair cable is used, the coupling level is kept low and the generated magnetic field is eliminated. For high frequency signals, a shielded cable must be used, with ground front and back to eliminate EMI interference.

Physical shielding is a metal package that covers all or part of the system to prevent EMI from entering the PCB circuit. This shield acts like a closed, grounded, conductive container, reducing the antenna loop size and absorbing EMI.