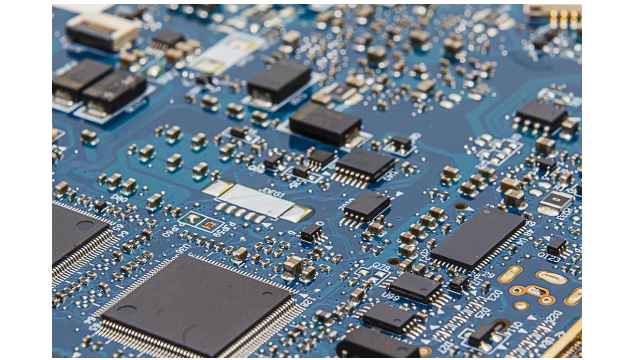

Generally, there are still a lot of needs to pay attention to in the production and processing of smt fast proofing factory. Whether smt fast proofing is also a fine occupation, especially smt fast proofing processing, in the process of production and processing needs to operate in strict accordance with the production specifications, to ensure the quality and reliability of products. SMT (short for Surface Mounted Technology) is one of the most popular skills and techniques in the electronics assembly profession. Surface Mount Technology (SMT) is called surface mount or surface mounting skills. It is a kind of pin-free or short lead appearance assembly components (SMC/SMD, Chinese known as chip components) installed in the Printed Circuit Board(PCB) appearance or other substrate appearance, after reflow welding or immersion welding and other methods to weld assembly of the circuit installation skills. Under normal circumstances, the electronic products we use are all made of pcb plus various capacitors, resistors and other electronic components according to the planned circuit diagram planning, so all kinds of electrical appliances need a variety of smt rapid proofing processing technology to process.

smt quick proofing factory smt quick proofing notice

First, it is necessary to use professional equipment cleaning agent for cleaning the welding appearance.

Two, after smt rapid proofing of the circuit board can not be stacked, otherwise it will cause physical harm to the board.

3. For EOS/ESD sensitive components and PCbas, appropriate EOS/ESD marking is required.

Four, maintain the operation table cleaning and clean and tidy. There should not be all kinds of food and drinks in the work area. Smoking, cigarette rolls and ashtrays are strictly prohibited.

5. Reduce the operation process of components to the minimum limit to prevent danger.

Six, the welding surface of the circuit board can not directly contact the human skin, otherwise the grease will affect the reliability of welding.

SMT patch,SMT patch processing,SMT patch processing factory, electronic smt patch processing, patch processing factory,PCB patch processing factory,SMT patch factory,PCB patch processing,pcba proofing,pcba urgent proofing,smt rapid proofing, Shenzhen patch processing,pcba small batch proofing,SMT patch proofing,sm t Patch factory, Shenzhen pcba,pcb proofing manufacturer, Shenzhen pcb proofing

100 thousand into one-stop PCBA intelligent manufacturing channels, research and development of template/small batch, SMT patches,PCB proofing, DIP welding processing,PCB board, electronic components full set of purchasing, partial purchasing one-stop PCBA manufacturing services.

After making samples in PCBA, we found that some pcb boards were small in size, so it is necessary to make splicing methods for production efficiency. When completing PCBA processing, PCBA splicing boards need to be spliced. Therefore, in the process of dividing the board, some precautions need to be paid attention to in order to avoid damaging the complete PCBA board.

When manually dividing plates, it is necessary to pay attention to that the lower edge of PCBA plate must be held by both hands when folding, 20mm above the V-shaped incision, to avoid bending and deformation and damage to PCBA electrical circuits, parts and tin slots.

Requirements of machine board:

1. Stable support point

Without support, the resulting stress may damage the substrate and weld points. Information hiding or obvious defects can develop as a result of twisting the plate or creating different stresses during the assembly process.

2. Wear protective tools

Before operation, prepare for protection and install a high frequency eye protection lighting device to protect the safety of operators. It's best to bring a pair of eyes to keep them safe.

3. Often wipe the spindle and tools of the machine tool with alcohol to remove PCB dust generated in the process of dividing the board and maintain the normal operation of the board.

4. When using a certain number of times, it is necessary to smooth the sliding block and bearing of the plate dividing machine, check whether the screws are loose, etc.

5, in the process of machine learning application and development, the workbench should adhere to a clean, it is best not to place other things, to avoid these things fall on the tool and form the damage of the tool and the damage of the item. Although there are electric eyes for management and maintenance, but in the actual use of the history of the process or we should pay attention to fingers and tools to maintain a certain safety protection interval.

In general, machine partitioning is more important than manual partitioning when using PCBA partitioning, and machine partitioning is more efficient and less corrupt. However, when the machine is divided, it is also done strictly according to the process to reduce human error. The above is a hundred thousand into the electronic small series to share, I hope that more people in the PCBA proofing has certain help.