Explanation of FR4 plate parameters and conventional thickness

Circuit board manufacturing, circuit board design, PCBA processing manufacturers explain FR4 plate parameters and conventional thickness

FR4 copper clad laminate is divided into the following levels:

First: FR-4 Grade A1 copper clad plate

This level is mainly used in military, communications, computers, digital circuits, industrial instruments, automotive circuits and other electronic products. The quality of this series of products has completely reached the world-class level, with the highest grade and the best performance.

Second: FR-4 Grade A2 copper clad plate

This level is mainly used for ordinary computers, instruments and meters, advanced household appliances and general electronic products. This series of copper clad laminate is widely used, and all performance indicators can meet the needs of general industrial electronic products. Very good price performance ratio. It can effectively improve the price competitiveness of customers.

Third: FR-4 A3 copper clad plate

This grade of copper clad laminate is the FR - 4 product developed and produced by our company for the home appliance industry, computer peripheral products and ordinary electronic products (such as toys, calculators, game consoles, etc.). It is characterized by its competitive price on the premise that the performance meets the requirements.

Fourth: FR-4 Grade A4 copper clad plate

This grade of plate belongs to the low end material of FR-4 copper clad plate. However, various performance indicators can still meet the needs of ordinary household appliances, computers and general electronic products. Their prices are the most competitive, and the performance price ratio is also quite excellent.

Fifth: FR-4 Grade B copper clad plate

The plates of this grade are relatively poor and have poor quality stability. They are not suitable for PCB products with large area, but generally suitable for products with a size of 100mm × 200mm. It is the cheapest and should be selected for use.

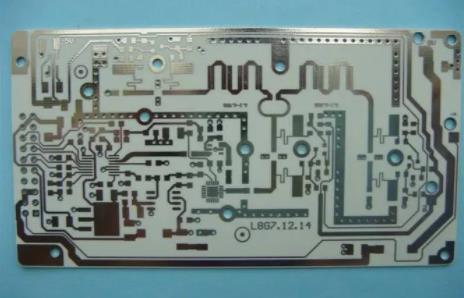

1. Parameter classification of FR-4 plate: dielectric constant parameter, dielectric loss parameter, TG value parameter

FR-4 board is a double-sided copper clad PCB board pressed by epoxy resin and glass cloth. The dielectric constant of FR4 copper clad board is 4.2-4.7 relative to air. This dielectric constant will change with temperature. In the temperature range of 0-70 degrees, the maximum change range can reach 20%. The change of the dielectric constant will cause a 10% change of the line delay. The higher the temperature, the greater the delay. The dielectric constant also changes with the signal frequency. The higher the frequency is, the smaller the dielectric constant is. Generally, the classical value of the dielectric constant is 4.4.

Dielectric constant (Dk, ε, Er) determines the speed of electrical signal propagation in the medium. The speed of electrical signal propagation is inversely proportional to the square root of the dielectric constant. The lower the dielectric constant, the faster the signal transmission. Let's make a visual analogy, just like you are running on the beach. The water depth submerges your ankles. The viscosity of water is the dielectric constant. The more viscous the water is, the higher the dielectric constant is, and the slower you run.

The dielectric constant is not very easy to measure or define. It is not only related to the characteristics of the medium itself, but also related to the test method, test frequency, and the state of the material before and during the test. The dielectric constant will also change with the change of temperature. Some special materials have been developed with consideration of temperature Humidity is also an important factor affecting the dielectric constant, because the dielectric constant of water is 70. A little water will cause significant changes

FR4 plate dielectric loss: the energy loss caused by dielectric conductivity and dielectric polarization hysteresis effect of insulating materials under the action of electric field. It is also called dielectric loss. Under the action of alternating electric field, the included angle between the current phasor and the voltage phasor flowing in the dielectric (power factor angle Φ) Residual angle of δ It is called dielectric loss angle. The dielectric loss of FR4 plate is generally 0.02, and the dielectric loss will increase with the increase of frequency.

TG value of FR4 plate: also known as glass transition temperature, generally 130 ℃, 140 ℃, 150 ℃, 170 ℃.

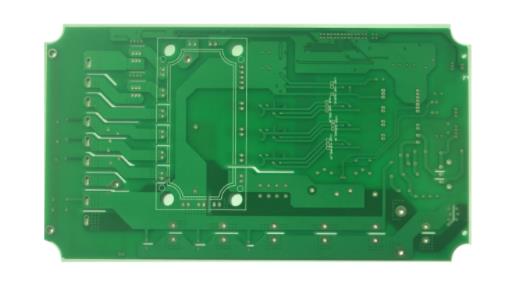

2. Conventional thickness of FR4 plate

Common thickness: 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 1.6mm, 1.8mm, 2.0mm. The thickness error of the plate depends on the production capacity of the plate factory.

Common copper thicknesses of FR4 copper clad laminate: 0.5 oz, 1 oz, 2 oz. Other copper thicknesses are also available. Please consult the PCB manufacturer for confirmation. PCB manufacturers, PCB designers and PCBA processors will explain FR4 sheet parameters and conventional thickness.