I believe you are familiar with PCB, but you may hear less about PCBA, and PCBA and PCB can be confused easily. What is the difference between PCBA and PCB? Let's take a look.

PCBA is the finished plate; PCB is bare board. Excellent circuit design in PCBA board can save production cost and achieve good circuit performance and heat dissipation performance. The function of PCB is to make a program that cannot run independently in a multi-program environment become a basic unit that can run independently, and a process that can run concurrently with other processes. Is a piece of program code that can be executed on the CPU by the process scheduler.

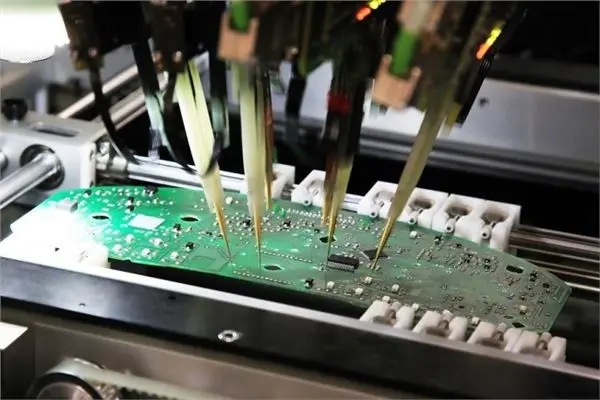

PCBA board essentially belongs to the production process. The PCB empty board goes through the SMT upper piece or through the whole manufacturing process of DIP plug-in. The PCB is the only indication that a process exists, and the PCB process control block is a static description of the process. PCB is the support body of electronic components, is the supplier of circuit connection of electronic components.

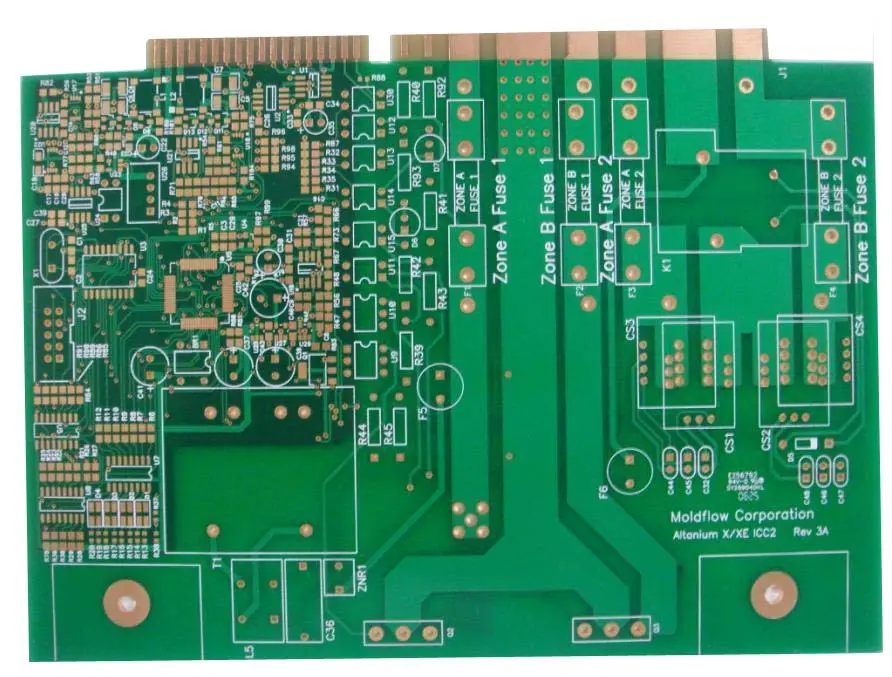

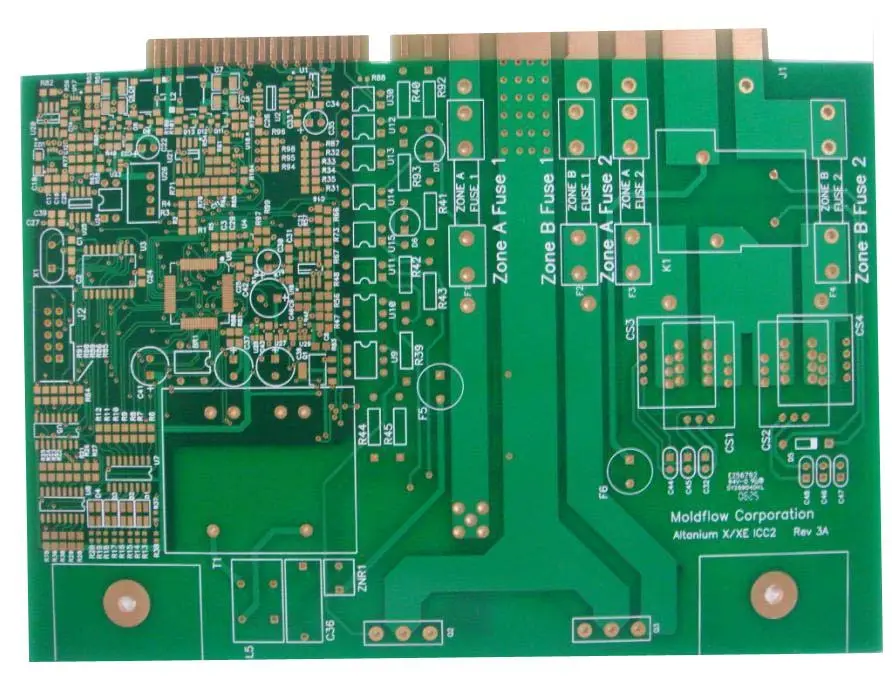

pcb

PCB is made by electronic printing, so the Chinese name is printed circuit board, is an important electronic part in the electronic industry, but also the support of electronic components.

PCBA

The full name of PCBA stands for Printed Circuit Board +Assembly, meaning the entire manufacturing process consisting of the PCB empty Board through the SMT upper component, and the DIP plug-in.

Pcba is the finished product of PCB board. After assembling some parts on PCB, PCBA is made. Pcba is a processing process, which can also be understood as the finished circuit board.

Pcba and PCB difference

1. Different functions PCB can make a program that cannot run independently become an independent unit. Excellent circuit design of PCBA can achieve good circuit performance and heat dissipation performance.

2. It's fundamentally different

PCBA generally refers to a processing process, which can also be said to be the finished circuit board, that is, the PCB is completed after processing. PCBA is an empty printed circuit board.

As basic components in optical communication networks, optical modules act as media between different types of devices to receive and send data. Today, although we can see a lot of information from the perspective of optical module construction and packaging, we believe that many people still have limited knowledge of the most common internal elements of information. In this article, we will provide you with some basic information about the various components inside an optical module.

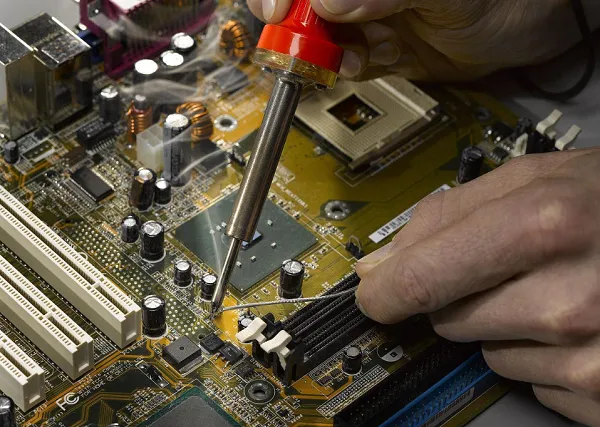

In the difference between PCB board and PCBA board, let's take a specific look. The first is the PCB board, which is usually called a printed circuit board because it is made by electronic printing. PCB board is a very important part in the electronic industry, is the pillar of electronic components, is the hub of electrical connection of electronic components. PCB has been widely used in the manufacture of electronic products, PCB board is widely used because PCB board has its own unique characteristics: high wiring density, small volume, light weight, conducive to the miniaturization of electronic equipment; Because of the repetitive and consistent characteristics of graphics, the difficulty of wiring and assembly is reduced, and the time of equipment maintenance, debugging and inspection is saved. At the same time, PCB board is also more conducive to quantitative production and use, which is also a major feature. PCBA board is the finished product of PCB board.

Generally speaking, PCBA is the whole manufacturing process of PCB empty board SMT and DIP plug-in. Like, some parts are assembled on the PCB board, and then like the PCBA board is formed through plug-ins on the PCB board. The process is more complex and requires more like. It pays attention to the precision of the product, and the manufacturing time is longer, so the quantified production like is less like the PCB board. This is also the reason why PCBA board is not as widely used as PCB board in the electronics industry. PCBA is a processing process, which can also be understood as the finished circuit board. PCBA can only be counted after all the processes on the PCB board are completed. A PCB is an empty piece of printed circuit board.

Compared with PCBA, PCB has the following advantages:

1. Maintainability. Because PCB products and components assembled parts are based on standardized design and large-scale production; Thus, these components have normative rationality. Once a fault occurs, it can be replaced efficiently, quickly, conveniently and flexibly, and quickly restore the service system.

2. Improve stability. Through a series of inspection, inspection and aging tests, PCB can be guaranteed to work reliably for a long time.

3, the ability to assemble. It is convenient for standardization and assembly, and can be automated and large-scale mass production. At the same time, PCB and components assembly parts can also be assembled into larger parts, systems, up to the whole machine.

4, can be productive. Using modern management, can be standardized, scale, automation and other production, to ensure product quality consistency.

5. Designability. PCB performance (electrical, physical, chemical, mechanical, etc.) requirements can be achieved by design standardization, standardization, etc.

6, can be high-density. With the improvement of integrated circuit integration and installation technology.

7. Testability. Establish complete inspection methods, inspection standards, and various inspection equipment and instruments to check and verify the conformance and service life of PCB sample products.

8, other: such as the system miniaturization, slight, high-speed signal transmission, etc.