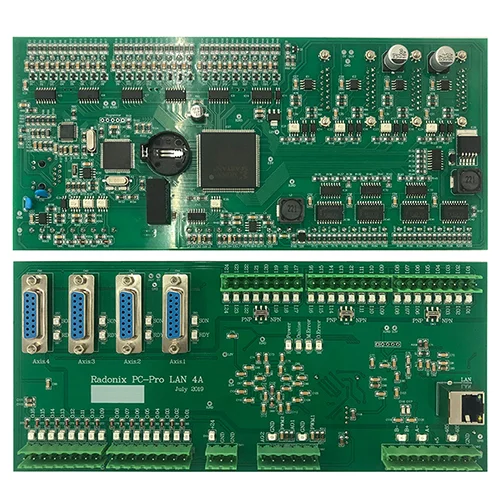

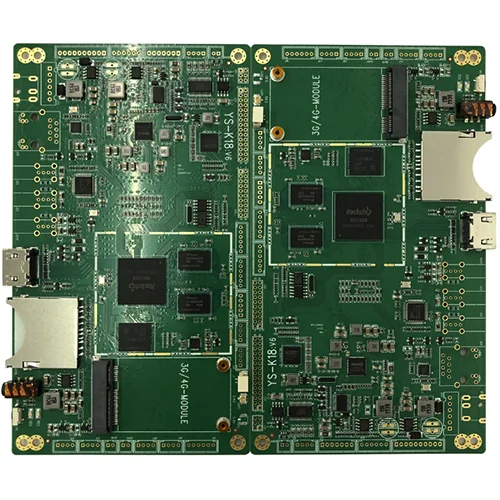

Industrial control board SMT processing

Name: Industrial control board SMT processing

Number of SMT lines: 7high-speed SMT patch supporting production lines

SMT daily production capacity: more than 15 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, with a pin pitch of ±0.04mm

IC type patch accuracy: It has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. It can be mounted/inserted/mixed with TFT display driver boards, mobile phone motherboards, battery protection circuits and other difficult products

SMT patch refers to the abbreviation of a series of process processes processed on the basis of PCB. PCB is a printed circuit board.

SMT is Surface Mount Technology (Surface Mount Technology) (abbreviation for Surface Mounted Technology), which is the most popular technology and process in the electronics assembly industry. Electronic circuit surface assembly technology (Surface Mount Technology, SMT), known as surface mount or surface mount technology. It is a kind of non-pin or short-lead surface mount components (SMC/SMD for short, Chinese called chip components) mounted on the surface of the printed circuit board (Printed Circuit Board, PCB) or the surface of other substrates, through Circuit assembly and connection technology that is soldered and assembled by methods such as reflow soldering or dip soldering.

Under normal circumstances, the electronic products we use are designed by PCB plus various capacitors, resistors and other electronic components according to the designed circuit diagram, so all kinds of electrical appliances need various SMT chip processing technology to process

Electronic products are pursuing miniaturization, and the perforated plug-in components used in the past can no longer be reduced. Electronic products have more complete functions, and the integrated circuits (IC) used have no perforated components, especially large-scale and highly integrated ICs, and surface mount components have to be used. Product mass production, production automation, the factory must produce high-quality products at low cost and high output to meet customer needs and strengthen market competitiveness. The development of electronic components, the development of integrated circuits (IC), and the multiple applications of semiconductor materials. The electronic technology revolution is imperative, and the pursuit of international trends. It is conceivable that when the production technology of international cpu and image processing device manufacturers such as intel and amd has improved to more than 20 nanometers, the development of surface assembly technology and technology such as smt is also unavoidable.

Advantages of smt patch processing: high assembly density, small size and light weight of electronic products, the volume and weight of patch components are only about 1/10 of traditional plug-in components, generally after using SMT, the volume of electronic products is reduced by 40%~60 %, the weight is reduced by 60%~80%. High reliability and strong anti-vibration ability. Solder joint defect rate is low. Good high frequency characteristics. Reduced electromagnetic and radio frequency interference. It is easy to realize automation and improve production efficiency. Reduce costs by 30% to 50%. Save material, energy, equipment, manpower, time, etc.

It is precisely because of the complexity of the process of smt patch processing that there have been many smt patch processing factories specializing in smt patch processing. In Shenzhen, thanks to the vigorous development of the electronics industry, smt patch processing has achieved prosperity of an industry

Name: Industrial control board SMT processing

Number of SMT lines: 7high-speed SMT patch supporting production lines

SMT daily production capacity: more than 15 million points

Testing Equipment: X-RAY Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station

Placement speed: CHIP component placement speed (at best conditions) 0.036 S/piece

The smallest package that can be attached: 0201, the accuracy can reach ±0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be mounted, with a pin pitch of ±0.04mm

IC type patch accuracy: It has a high level for mounting ultra-thin PCB boards, flexible PCB boards, gold fingers, etc. It can be mounted/inserted/mixed with TFT display driver boards, mobile phone motherboards, battery protection circuits and other difficult products