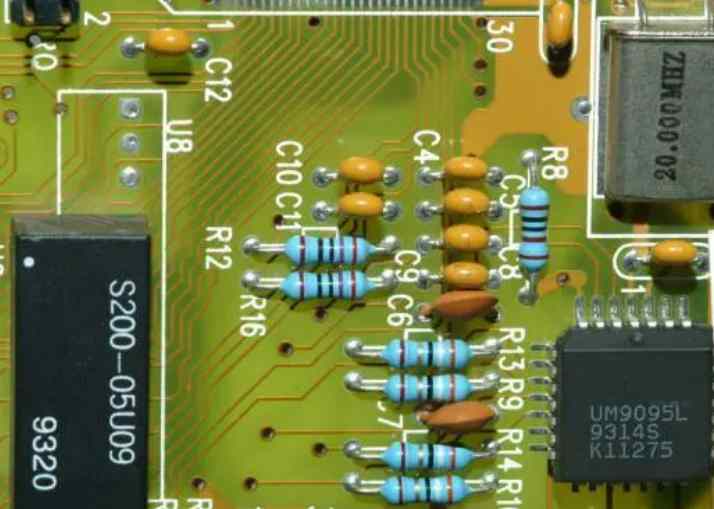

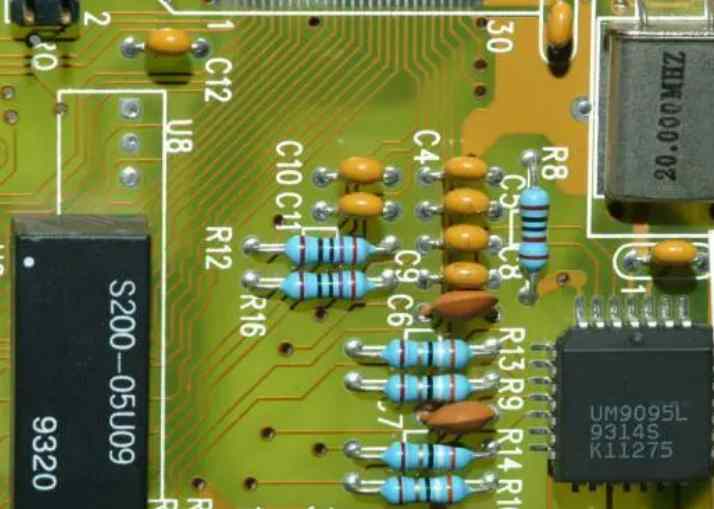

First-class production comes from first-class design. The production of Keyou circuit cannot be separated from your design. Every engineer, please design according to the detailed description of the conventional production process.

one via holes (commonly known as conducting holes)

1. Minimum aperture :0.3mm(12mil)

2, the minimum hole (VIA) aperture is not less than 0.3mm(12mil), the single side of the pad can not be less than 6mil(0.153mm), the best greater than 8mil(0.2mm) is not limited to this point is very important, the design must be considered

3, through the hole (VIA) hole to hole spacing (hole edge to hole edge) can not be less than :6mil better than 8mil this point is very important, the design must be considered

4. Spacing between pad and contour line 0.508mm(20mil)

Keyou Circuit specializes in the production of PCB rapid proofing and batch, with high precision single side/double side/multilayer circuit board (1-26 layers), thermoelectric separation copper substrate, multilayer industrial control circuit board, medical circuit board, security PCB board, communication PCB board, automotive circuit board, composite bus copper substrate, foldable metal substrate, etc.

two line

1. Minimum line distance: 6mil (0.153mm).. Minimum line distance, that is, line to line, line to pad distance is not less than 6mil from the production point of view, the bigger the better, generally in 10mil, of course, under the condition of design conditions, the bigger the better this point is very important, the design must be considered

2. Minimum line width: 6mil (0.153mm). That is to say, if the line width is less than 6mil, the production will not be possible (the minimum line width of the inner layer of multilayer board is 8MIL). If the design conditions permit, the larger the design, the better, the larger the line width, the better our Huaqiang PCB factory production, the higher the yield, the general design routine around 10mil is very important, the design must be considered

3. Distance between line and contour line 0.508mm(20mil)

Three. PAD pad pad (commonly known as plug-in hole (PTH))

1, plug-in hole (PTH) welding disc outer ring side can not be less than 0.2mm(8mil) of course, the bigger the better this point is very important, the design must be considered

2, plug-in hole (PTH) hole to hole spacing (hole edge to hole edge) can not be less than: 0.3mm of course, the bigger the better this point is very important, the design must be considered

3. The size of the plug-in hole depends on your components, but it must be larger than the pin of your components. It is recommended that the pin of the components should be larger than 0.2mm at least, that is to say, 0.6.

4. Spacing between pad and contour line 0.508mm(20mil)

Four. solderproof

1. Plug-in window opening, SMD window opening side shall not be less than 0.1mm(4mil)

Five. Character (the design of the character directly affects the production, whether the character is clear or not is very relevant to the character design)

the character width can not be less than 0.153mm(6mil), the height of the word can not be less than 0.811mm(32mil), the ratio of width to height of the best 5 relationship is that is to say, the word width of 0.2mm word height of 1mm, to push the class

Six. The minimum spacing of non-metallic slot holes is not less than 1.6mm, otherwise it will greatly increase the difficulty of milling

Seven. Patchwork

1, there is no gap patchwork, and gap patchwork, gap patchwork gap should not be less than 1.6 (plate thickness 1.6) mm otherwise it will greatly increase the difficulty of milling edge patchwork plate size depending on the equipment is not the same, no gap patchwork gap about 0.5mm process edge can not be less than 5mm

Battery circuit board: What battery is used in new energy vehicles?

Almost every once in a while, news of new energy batteries and battery boards has popped up about Tesla. Toyota's hydrogen electric car, aluminum battery electric car that can run 1600 kilometers, flow battery car that can run 600 kilometers on a single charge, graphene battery, aluminum ion battery... It may seem like we're stupid to be using lithium-ion batteries now, and that a new energy revolution is long overdue, but is it really as good as the news makes it sound? Please follow the battery circuit board small make up a look.

The core technology of an electric vehicle is the battery, the motor, the electrical control and the battery circuit board, and then the chassis technology in a traditional car and things like that. Among them, motor technology is now relatively mature, electric control is also progressing with Moore's law, automotive chassis technology has been developed for so many years, not to say bottleneck.

The core problem with electric cars is the battery. For electric vehicles, the ideal battery should have the following characteristics:

1. Enough energy density, enough capacity per unit volume per weight, so as to run longer distances.

2. There is enough power density, unit volume unit weight can produce enough power, so that the car can accelerate fast, to climb.

3. Recharge quickly, charge or change quickly, or limit yourself to city commuting, running during the day and charging at night.

4. The average cost of use should be cheap, and the combined life and price should be competitive.

Now the electric car has been on the market, there are mainly two kinds of batteries, a high-speed electric car lithium ion battery, including lithium manganese acid, lithium three yuan battery and so on. There is also the lead-acid battery of low-speed electric vehicle. According to the requirements of electric vehicle, the power density and energy density of lithium battery are good, but the charging is not fast and the price is high. Without subsidies, it can only be used for high-positioning models like Tesla. Lead-acid batteries have low power density and energy density, and charge slowly, but they are relatively cheap and suitable for short-distance low-speed electric vehicles. But there are pollution problems and now China is not encouraging development.

This battery, this battery, that battery, unfortunately, has not yet been mass-produced on the road, and there are several experimental bus routes in use. Really passed the test of practice, the reality can be large-scale use of these two. The advanced batteries in this myth are either not reliable at all, or they're still in the lab.