Some knowledge of HF board and five difficulties in Rogers HF board production

PCB manufacturing, PCB design and PCBA processing manufacturers will explain some knowledge about high-frequency boards and the five difficulties of Rogers high-frequency board manufacturing

With the reform and improvement of domestic industrial technology, such as the emergence of 5G mobile communications, the Internet of Things, health care, aerospace, artificial intelligence, etc., the domestic demand for high-frequency boards is gradually rising. More and more high-frequency board manufacturers have transformed or are ready to transform the production of high-frequency boards in order to comply with the industrial development trend. Then I will give you a brief introduction of high-frequency boards.

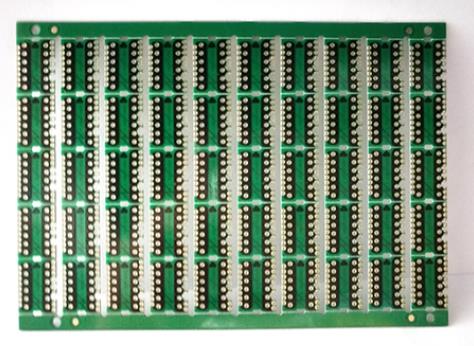

1、 Introduction

For special PCB with high electromagnetic frequency, generally speaking, high frequency can be defined as frequency above 1GHz. Its physical performance, accuracy and technical parameters are very high, and are commonly used in automotive anti-collision systems, satellite systems, radio systems and other fields. The price is high, usually around 1.8 yuan per square centimeter, about 18000 yuan per square meter.

2、 Meaning

Whether the design of the short circuit protection function of the driver is perfect is crucial to the safe operation of the power supply. It is necessary to test whether the short-circuit protection function of a driver circuit is perfect before using it.

3、 Precautions

For HF driver and drive board with protection function, if users want to test normal static (without main power) output waveform, they should pay attention to the following points:

If the power tube IGBT or MOSFET has been connected in the circuit, the corresponding output signal can be seen with an oscilloscope at the output end by adding the drive power supply and PWM input signal.

2. If the power tube is not connected and only an output test is being conducted, the two points that should be connected to the collector and emitter (or drain and source) of the power tube must be short circuited. Because if the collector or drain is suspended, the driver or the drive board will think that the power tube is in a short circuit state and start the internal protection mechanism. At this time, the protection signal waveform output by the driver will be seen. Both the waveform shape and cycle are completely different from the input PWM signal. The main problem to be solved in the application of IGBT is how to implement relatively perfect protection for IGBT in the case of overcurrent, short circuit and overvoltage. Overcurrent fault usually takes a little longer to overheat the power supply, so its protection is all solved by the main control board. Overvoltage generally occurs when the IGBT is turned off, and the larger one generates higher voltage on the parasitic inductance, which requires a buffer circuit to clamp, or appropriately reduce the turn off rate. After a short circuit fault occurs, a huge current will be generated instantaneously, which will soon damage IGBT. The over-current protection of the main control board is simply too late, and must be immediately protected by the drive circuit or driver.

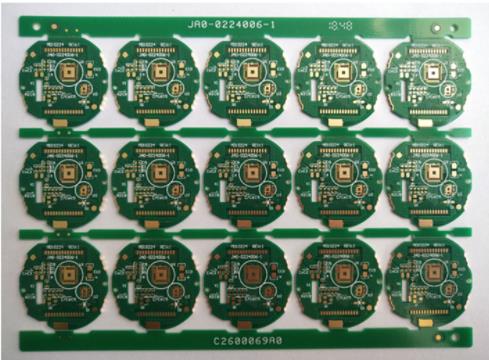

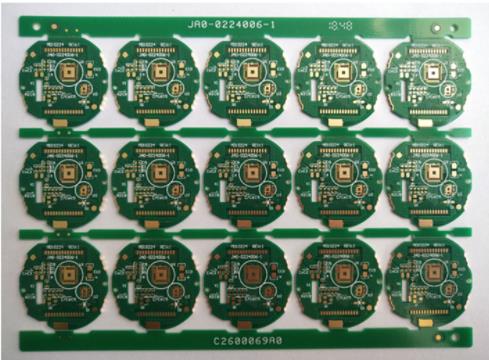

Five Difficulties in Making Rogers High Frequency Board

Rogers high frequency board is a kind of high frequency pcb. its physical performance, accuracy and technical parameters are very high, and it is commonly used in automotive anti-collision systems, satellite systems, radio systems and other fields. What are the manufacturing difficulties of Rogers HF board?

Because the characteristics of PCB Rogers high-frequency board itself determine the manufacturing difficulty:

Before resistance welding, the plate cannot be ground, otherwise the adhesion will be very poor, and can only be roughened with micro etchant water.

2. The impedance control requirements are relatively strict, and the line width control is very strict. The general tolerance is about 2%.

3. Rogers plates are mostly made of polytetrafluoroethylene. There will be many rough edges when they are formed with ordinary milling cutters, so special milling cutters are required.

4. PCB Rogers high frequency circuit board is a special circuit board with high electromagnetic frequency. Generally speaking, high frequency can be defined as the frequency above 1GHz.

5. Due to the special PCB board, the adhesion of PTH copper deposition is not high. It is usually necessary to roughen the vias and surfaces with the help of plasma treatment equipment to increase the adhesion of PTH copper and solder resist ink. PCB manufacturing, PCB design and PCBA processing manufacturers will explain some knowledge about high-frequency boards and the five difficulties of Rogers high-frequency board manufacturing.