Selection of high-frequency board manufacturers and precautions for board production

PCB manufacturers, PCB designers and PCBA manufacturers explain how to select high-frequency board manufacturers and what should be paid attention to in board production

With the development of 5G market, high frequency boards are needed in communication equipment, medical electronics, security industrial control, slot antenna, RF antenna, broadband antenna, frequency scanning antenna, microstrip antenna, ceramic antenna, power splitter, coupler, combiner, power amplifier, dry amplifier, base station, smart car and other aspects, especially in the communication field, high frequency high-speed configuration is required. We are now a 4G network, and the next 5G is 20 times the current 4G network, which means that it only takes us a few seconds to download a movie. The requirement of high frequency and high speed for communication will definitely require the hardware of high frequency board. Rogers high frequency board, Rogers circuit board, microwave equipment board, high frequency microwave circuit board, and high frequency ceramic board will have a new demand breakthrough point. How can enterprises in these application fields find high-quality high-frequency board manufacturers?

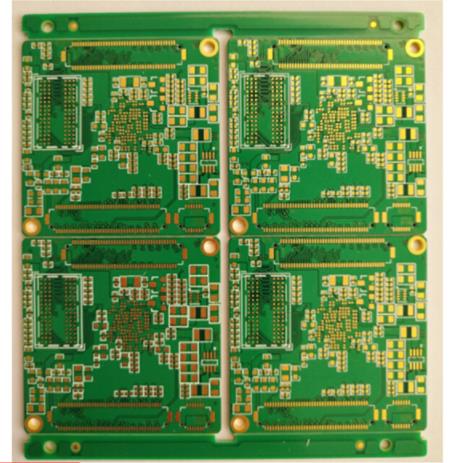

1、 PCB high-frequency board

High frequency board materials are required for high frequency communication electronics. High frequency materials led by Rogers need to be imported, and the cycle will be relatively long; Some ceramic high-frequency pcbs also need imported ceramic plates.

2、 Strict quality management system

System and team cooperation are very important. Only by ensuring the quality and plan, can we reduce the replenishment, increase the yield of products and ensure the product performance.

3、 Advanced equipment requirements

High frequency boards need high-precision equipment to improve product performance and yield. For example, high frequency boards need laser drilling machine+LDI laser exposure machine.

4、 It depends on whether there is a similar high-frequency board model. The case of cooperation is also an aspect of the assessment.

High frequency microwave board: what should be paid attention to in board production

1、 Preface

With the continuous development of science and technology, especially information technology, the technology of high-frequency circuit board production has been improved to meet the needs of different users. In recent years, with the rapid development of communication, automobile and other fields, the demand for high-frequency circuit boards has changed, and the demand for high-power high-frequency circuit boards and high-frequency microwave boards has increased. Many bosses of high-frequency circuit board manufacturers are optimistic about this growth point, but enterprises must practice their internal skills to do well in high-frequency microwave boards. Let's discuss the matters needing attention in the production process of high-frequency microwave board.

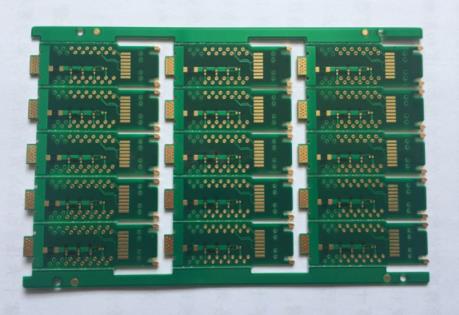

2、 Basic requirements for high frequency microwave board

During the design, the base material telecommunication engineer has selected the specified dielectric constant, dielectric thickness and copper foil thickness according to the actual impedance needs. Therefore, when accepting the order, it should be carefully checked to meet the design requirements.

2. The manufacturing accuracy of transmission lines requires the transmission of high-frequency signals. The requirements for the characteristic impedance of printed wires are very strict, that is, the manufacturing accuracy of transmission lines is generally ± 0.02mm (transmission lines with an accuracy of ± 0.01mm are also common). The edges of transmission lines should be very neat, and no small burrs or gaps are allowed.

3. The coating requires that the characteristic impedance of the transmission line of the high-frequency microwave plate directly affects the transmission quality of the microwave signal. The characteristic impedance has a certain relationship with the thickness of the copper foil. Especially for the microwave plate with metallized holes, the coating thickness not only affects the total thickness of the copper foil, but also affects the precision of the conductor after etching. Therefore, the size and uniformity of the coating thickness should be strictly controlled.

4. Requirements for mechanical processing First, the materials of high-frequency microwave board are very different from the epoxy glass cloth materials of printed boards in terms of mechanical processing; Secondly, the processing accuracy of the high-frequency microwave board is much higher than that of the circuit board, and the general contour tolerance is ± 0.1mm (generally ± 0.05mm or 0~-0.1mm for those with high accuracy).

5. The requirements of characteristic impedance have been mentioned previously. It is the most basic requirement of high-frequency microwave board, and it cannot meet the requirements of characteristic impedance. Everything is futile. PCB manufacturers, PCB designers and PCBA processors will explain how to select high-frequency board manufacturers and what should be paid attention to in board production.