Rogers RO4350B/RO4450B and FR4 composite high-frequency composite board

Circuit board manufacturing, circuit board design and PCBA processing manufacturers will explain to you the high-frequency composite board made of Rogers RO4350B/RO4450B and FR4 materials

Printed circuit boards, also known as printed circuit boards, are providers of electrical connections for electronic components.

Printed circuit board is usually represented by "PCB", not "PCB".

PCB design is mainly layout design; The main advantage of using circuit board is to greatly reduce wiring and assembly errors, and improve the automation level and production labor rate.

High frequency circuit board is a special circuit board with high electromagnetic frequency. Generally speaking, high frequency can be defined as the frequency above 1GHz. Its physical performance, accuracy and technical parameters are very high, and are commonly used in automotive anti-collision systems, satellite systems, radio systems and other fields.

With the rapid development of electronic communication technology, in order to achieve high-speed and high fidelity transmission of signals, more and more high-frequency printed circuit boards (high-frequency boards) are used in communication equipment. The dielectric materials used in high-frequency boards have excellent electrical properties and good chemical stability, which are mainly shown in the following four aspects:

1. High frequency board has high-precision control of characteristic impedance (Zo);

2. High frequency plate has excellent heat resistance (Tg), processing formability and adaptability;

3. High frequency board has the characteristics of small signal transmission loss, short transmission delay time and small signal transmission distortion;

4. High frequency plate has excellent dielectric properties (mainly: low relative dielectric constant Dk, low dielectric loss factor Df). Moreover, this dielectric property (Dk, Df) can still maintain its stability under the environmental changes of frequency, humidity and temperature.

Based on the above characteristics, high-frequency boards are widely used in wireless antennas, base station receiving antennas, power amplifiers, components (splitters, combiners, filters), radar systems, navigation systems and other communication equipment.

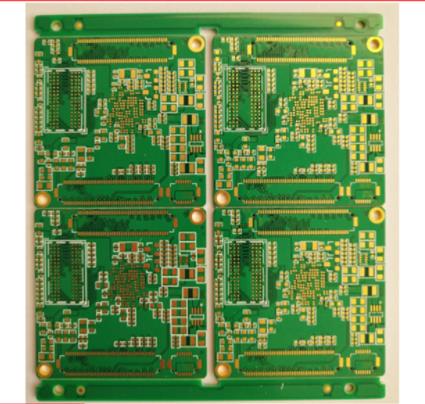

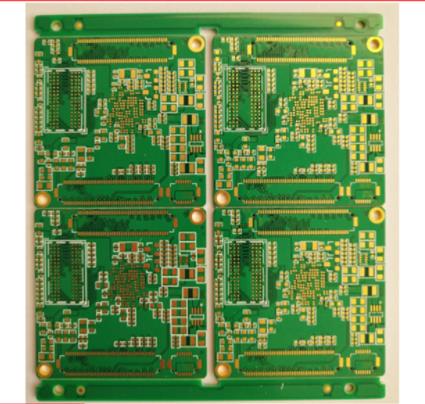

Multi layer high frequency plate design, based on cost saving, improving bending strength, electromagnetic interference control and other factors, often appears in the form of high-frequency composite plate, which is called high-frequency composite plate. There are many kinds of high frequency mixed compression materials selected and designed for lamination and combination, which are too numerous to enumerate.

The trial production results show that, based on one or more factors in cost saving, bending strength improvement and electromagnetic interference control, the composite design of high-frequency composite laminates must adopt high-frequency semi solidified sheets with low resin fluidity in the pressing process and FR-4 glass fiber substrate with smooth medium surface. In this case, there is a greater risk for the product adhesion control in the pressing process.

The experiment shows that by selecting FR-4A material, the design of the plate edge spherical flow stop, the use of pressing and retarding materials, the control of pressing parameters and other key technologies, good adhesion between (high-frequency plate) high-frequency mixed materials is achieved, and the reliability of high-frequency plate is normal after testing. PCB manufacturing, PCB design and PCBA processing manufacturers will explain to you the high-frequency composite board made of Rogers RO4350B/RO4450B and FR4 materials.