Circuit board factory: why should we carry out high-frequency board proofing

Circuit board manufacturer, circuit board designer and PCBA manufacturer explain to you why the circuit board manufacturer should carry out high-frequency board proofing

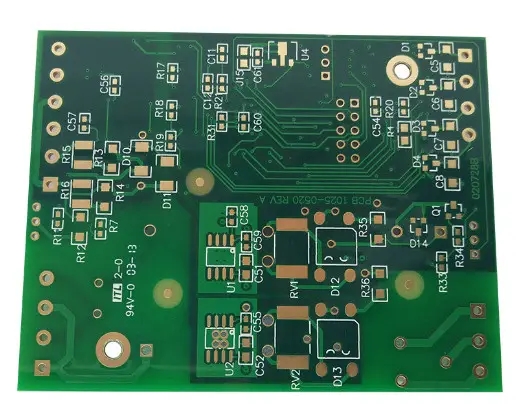

High frequency circuit board is a special circuit board with high electromagnetic frequency. Generally speaking, high frequency can be defined as the frequency above 1GHz. Its physical performance, accuracy and technical parameters are very high, and are commonly used in automotive anti-collision systems, satellite systems, radio systems and other fields.

It is believed that all customers who process and produce high frequency boards understand that proofing is required before mass production. High frequency board proofing is not only to understand the quality response of products in advance, but also to reduce the defects in formal production. Therefore, it is an indispensable link to conduct high-quality high-frequency board proofing in advance. Of course, both parties should deeply communicate the details and specific parameters before HF plate proofing, so as to promote the success of HF plate proofing and lay a foundation for subsequent production. Now let's talk with Xiao Bian about the purpose of proofing:

First, be able to judge the strength level of high-frequency circuit board manufacturers

Effective HF board proofing before production can also clearly understand the strength of the manufacturer. In particular, if the two parties have not cooperated with HF board manufacturers before, the strength and capability of the manufacturer in production can be determined through proofing. Only manufacturers with equivalent capabilities and can meet the standard requirements in processing technology can better meet the requirements of long-term cooperation and high-quality processing and production of HF boards.

Second, it can reduce the defective rate of bulk products during production

Usually, there is a large amount of high-frequency plate processing and production. In order to ensure the smooth mass production without quality problems and reduce the defective rate, it is very necessary to carry out the high-frequency plate proofing processing before production. After all, the processing of high-frequency boards needs to go through complicated processing procedures, and no errors can occur in each process or processing link. After the successful proofing of high-frequency boards, professional technicians will carry out effective tests on the samples. After passing various professional tests, they can determine that there are no problems before mass production.

Third, it can lay a foundation for future batch processing

High frequency board proofing is also to know the performance and functional response of new products in advance. Through proofing, it can effectively lay a good foundation for future mass production, and the corresponding material cost can also be calculated to optimize the deficiencies in advance. These need to be effectively handled in the proofing process, so as to reduce the occurrence of various unexpected problems in mass production.

It can be seen that it is very necessary to carry out HF plate proofing before formal production, and it is also the first step to successfully cooperate with processing enterprises. Therefore, we should select a HF plate manufacturer with reasonable price for proofing, and provide the manufacturer with the material size or size requirements required for plate processing. Formal HF plate proofing should be carried out after mutual communication and negotiation, which also lays a good foundation for better cooperation between the two parties in the future.

PCB manufacturers, PCB designers and PCBA manufacturers explain to you why PCB manufacturers need to carry out HF board proofing.