Common faults and solutions of coating in circuit board factory

The circuit board manufacturer, circuit board designer and PCBA processor explain the common coating faults and solutions

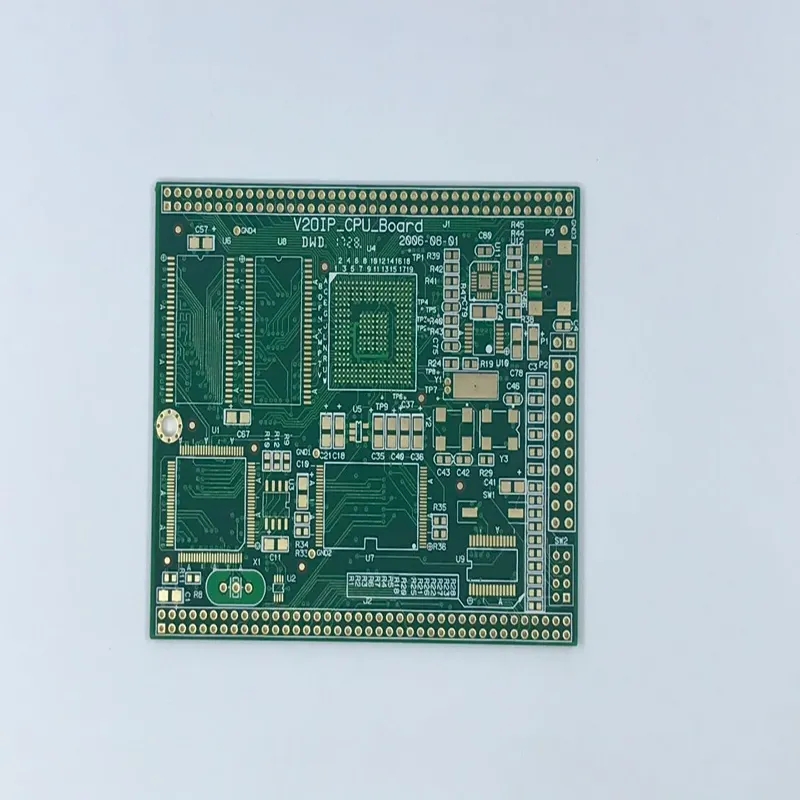

PCBA processing is to connect various electronic components on PCB board through surface mount (SMT), plug-in (DIP) and other electronic assemblies. PCBA process flow mainly includes SMT, AOI, DIP, FCT testing and other processes. Due to the size difference of electronic components, there will be different processes and requirements in assembly and insertion. The assembly density of PCBA is relatively high, and the small size and light weight of electronic products also have certain changes and requirements in mounting. The reliability, seismic resistance and excellent weldability of the products have high requirements for the hardware and software facilities of PCBA processing.

We have a good understanding of various processes in the Circuit Board Factory (Shenzhen Circuit Board Factory). The previous small editor introduced many technological processes related to graphic transfer. Today, the small editor introduced the coating methods in graphic transfer, common faults in coating and solutions.

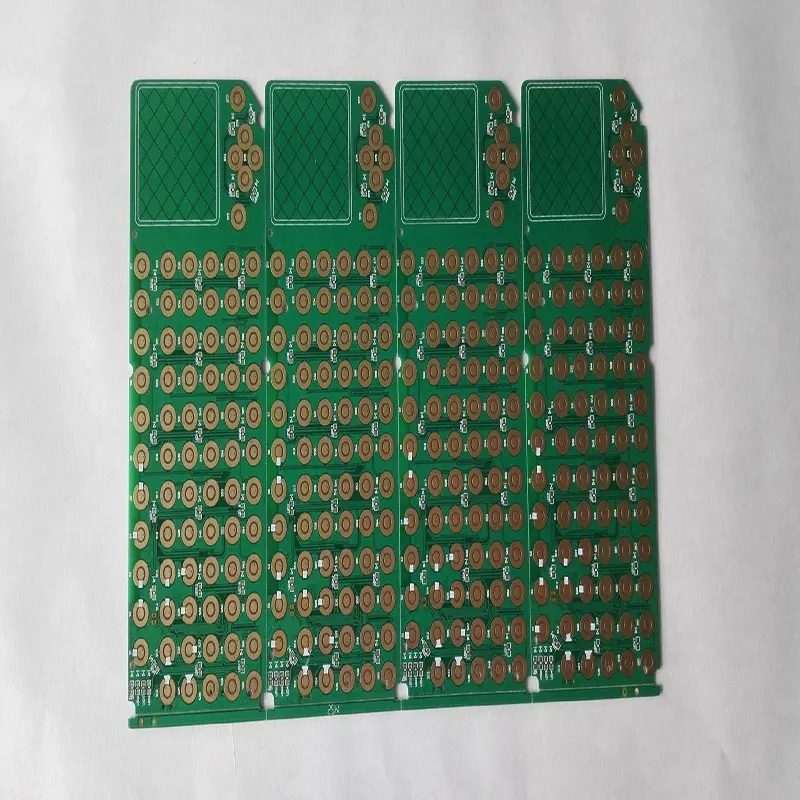

The common coating methods of Shenzhen Circuit Board Factory are as follows:

The coating methods of liquid photoresist in circuit board factory (Shenzhen circuit board factory) include screen printing, stick coating, Curtain Coating and Spray Coating

a. Screen printing is a commonly used coating method at present, which has the advantages of small equipment investment and no need for stiffening equipment; The operation is relatively simple; Low cost. But the screen printing coating production efficiency is low, and the consistency is difficult to control.

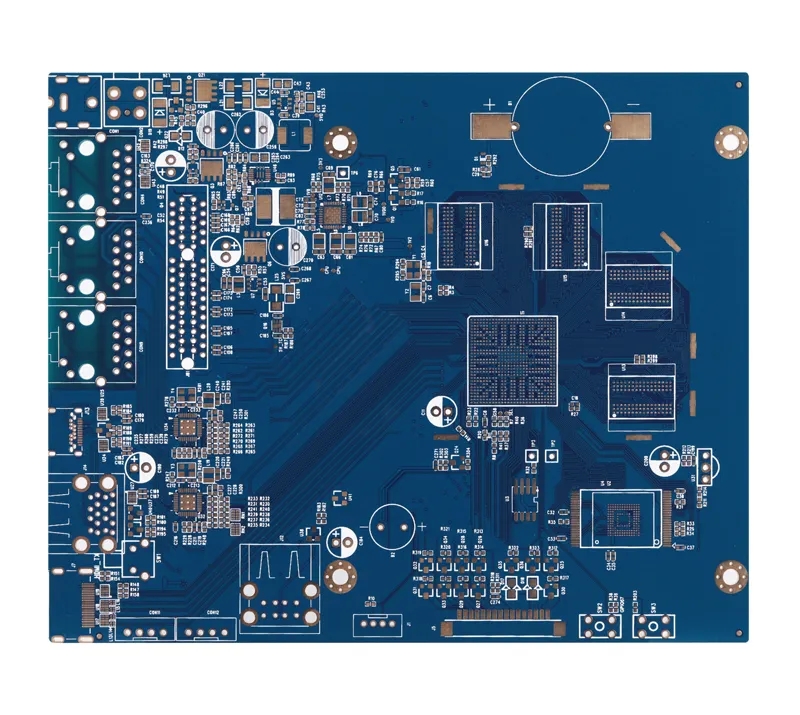

Common faults and solutions of coating in Shenzhen Circuit Board Factory

B. The biggest advantage of roller coating is that it can realize the coating of both sides of the board at the same time, and can realize the connection between coating and drying, with high efficiency; Wide range of plate thickness and film thickness. But new equipment investment is required; The thickness tolerance range of the same batch of plates shall be consistent; The board surface shall be flat.

c. Simple curtain coating operation; Little waste of raw materials; High efficiency; The film thickness is uniform and the film thickness range is wide. But the equipment investment is large; Board coating is to turn over one side and then paint the other side after coating, which affects the improvement of production efficiency.

d. The biggest advantage of spraying is that the flatness of the board surface is not required, and the rough or uneven copper foil surface can also be sprayed; The range of plate thickness is wide. But new equipment investment is required and the price is expensive; Material waste is large.

Common faults and solutions in coating of Shenzhen Circuit Board Factory:

1. The film thickness is uneven, and the ink viscosity is too small, so it is necessary to add thinner to adjust it to normal viscosity;

2. If the roller gap is too small, adjust the parent roller gap;

3. The roller speed is too slow, so speed up the roller coating;

4. If the ink discharge width is too small, increase the ink discharge valve flow

PCB manufacturers, PCB designers and PCBA processors will explain common coating failures and solutions.