Analysis of the fundamental elements endangering the weldability of PCBA

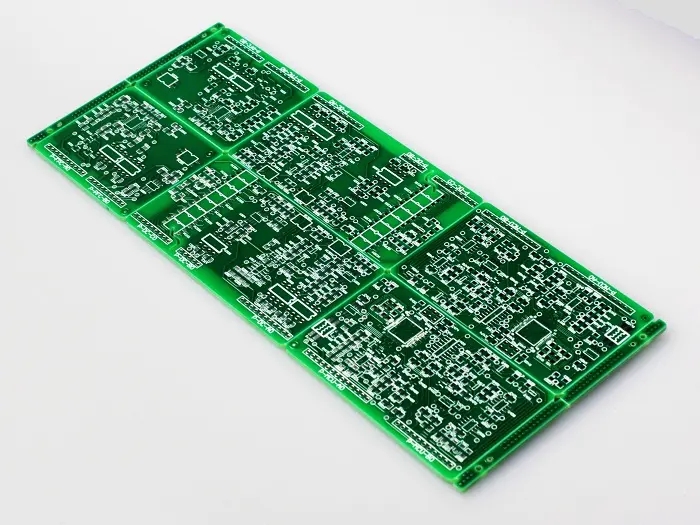

In the production process of PCBA circuit board, the solderability of PCBA circuit board immediately endangers the quality of commodities, and some inadvertent errors will cause the solderability of PCBA circuit board. PCBA processes PCB and DIP by integrating parts on PCBA circuit board. The key difference is that PCB does not need to drill holes on PCBA circuit board. In DIP, the PIN PIN of the part must be inserted into the hole already drilled. It is very important to master the fundamental elements that endanger the weldability of PCBA.

In fact, the weldability of PCBA circuit board electric welding is the influencing factor of PCBA circuit board electric welding, and the key decision is made by the following four factors. PCBA circuit boards are pasted on PCBA circuit boards by using the pasting machine. The production process is as follows: PCBA circuit boards are precisely positioned, printed soldering paste is packaged, the pasting machine is used for pasting, the soldering furnace is passed, and the finished products are inspected. With the development of science and technology, PCB can also carry out the placement of some larger parts. The characteristics of solder paste play a key role in the solderability of PCBA PCB. Factors such as different solder paste components and inconsistent storage standards are harmful to the solderability of PCBA PCB. The quality of PCBA circuit board base steel plate PCBA processing The production and manufacturing process of PCBA circuit board will also endanger the solderability of PCBA circuit board, and PCBA circuit board usually has a large product quality problem. If the PCBA circuit board is damaged, the electric welding of all PCBA circuit boards will be poor. It is quite serious. 3. Parts and components are used as electric welding parts. When parts are oxidized and wet and cold, short circuit fault, crack and other defects are easily caused in the whole process of electric welding. In the natural environment of PCB production workshop, the manipulation of the natural environment is very critical. There are often regulations on temperature and environmental humidity. Too high and too low temperatures are critical hazards to the electric welding weldability of PCBA circuit boards.

In fact, the harm to PCBA weldability is relatively complex. Solder paste, PCBA circuit board, electronic devices and natural environment are the fundamental elements that endanger the solderability of PCBA. According to the manipulation of these four elements, the product quality can be reasonably improved.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the fundamental elements that endanger the solderability of PCBA.