1. Don't forget to add capacitive filtering at the power input and output terminals

Generally, the electrical signals at the input and output terminals of the power supply are unstable, which directly supplies power to the load, causing damage to the load for a long time, and also making the work unstable. As we know, capacitors can store energy and filter voltage. The electronic charge is stored in the capacitor. The electronic charge is continuously accumulated in the capacitor, and then it is stably output - stable output without fluctuation, so that the load can get a steady and continuous input. A stable voltage without any fluctuation can make the load work more reliably without damaging the device. The voltage supplied to the load by the capacitor is used for filtering. From an empirical point of view, the general large electrolytic capacitor is used together with a 104 capacitor for filtering. The large capacitance is used to filter low-frequency waves, and the small capacitance is used to filter high-frequency waves. The combination of the two has the best effect.

2. Don't let the useless power be too large

In PCB circuit design, we should try our best to reduce the useless power as much as possible, so as to improve the power factor. If the heat on the board accounts for a large part in the PCB circuit design, the power output of the board backward will be reduced. If the power consumption on a board increases, when the output power of the board is unchanged, the input power of the board is required to be large, which will consume more power.

3. Do not randomly select the power of components

Each electronic component has different power. The power selection is large and the price of electronic components is high, which increases the cost; If the power selection is small, it will cause the electronic components to heat up. Long term operation in high temperature will shorten the service life. The power of electronic components shall be reasonably selected by calculating the power consumption of the components in the PCB circuit. When the rated power of a component is known, it is better not to exceed its rated power when designing the PCB circuit, otherwise it needs to add a radiator. When the current flowing through the component is relatively large, we should ensure that the pressure difference between the two sides is not too large. That is, if we choose the value of the current flowing through it, then the pressure difference on both sides of it will have a maximum critical value.

4. Do not neglect the basic characteristics of components

As an electronic engineer, if you want to be able to design a better PCB circuit, you should be able to flexibly use the basic characteristics of electronic components, match and combine the working principles and characteristics of existing components we have learned, and then form PCB circuits with different functions to meet the project requirements. For example, the diode's unidirectional conductivity, reverse withstand voltage, clamping and other important characteristics; Reverse voltage stabilizing characteristic of voltage stabilizing tube; The flow control flow pattern of the triode and so on.

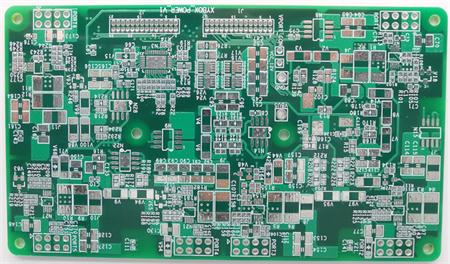

5. Don't forget to package common electronic components

Packaging of electronic components is actually the appearance of components, including the dimensions of components. In the process of PCB circuit design, we should be familiar with the packaging of components. When we talk about a package, we can know what it is in our mind, come up with it and form a concept. First of all, in the production process, the difference of packaging involves production welding technology. Secondly, in PCB layout design, packaging determines the appearance of the board. Be familiar with common packaging, and get twice the result with half the effort in the process of component selection.

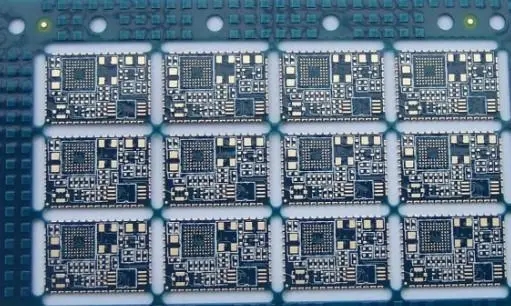

6. Don't neglect modular design

The hardware design is the same as the software programming. When writing a software program, each function is made into a function module. In different projects, the same function module is sometimes used. For example, lighting, communication, we write it as a fixed function module. When we need to use it in different projects, we can directly copy it and use it. This greatly reduces the time we spend writing programs and improves efficiency. We call it modular management. Therefore, for hardware engineers or senior engineers, we should also carry out modular design in the process of PCB circuit design, which greatly reduces the time for module design, improves the design efficiency and makes our design simple. It is also unnecessary to do the same work repeatedly in a project.

7. Don't ignore costs

As an electronic engineer, you must pay special attention to the cost of products, which is the red line from the beginning to the end of the project. For a company, its products will eventually be sold in the market for profit. If the product you design is too expensive, no one will want it even if you do it well. Finally, the project will fail. For an excellent engineer, the cost should be taken as one of the measures to measure the quality of the scheme at all times.

8. Don't position yourself too low

To improve your confidence, you should not be happy just because a product is made. Excessive excitement will blind people. You should always ask yourself what my competitive advantage is compared with other engineers' products.

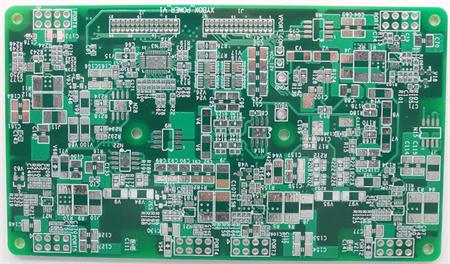

9. Don't copy a PCB circuit of others casually

The schematic design, in which each component is carefully selected and calculated, has scientific basis. For an electronic engineer, if he just copies other people's PCB circuits, he will never grow up. Because we don't know the advantages and disadvantages of the copied PCB circuit. Don't copy other people's PCB circuits casually. We must design PCB circuits according to our own knowledge. Even when you see someone else's PCB circuit, you should be able to analyze and understand them, find out the problems in the PCB circuit, and then turn them into your own PCB circuit, which is what the designer needs to do.

10. Don't neglect the cultivation of engineers' habits

The good habits of engineers are mainly to cultivate the depth and breadth of thinking and the preciseness of design. People's thinking, or we call it ability, the level of thinking is shown in the level of ability. The difference between people is not in IQ, but in thinking. The depth and breadth of thinking determine how far a person can go in a certain field in the future. Therefore, the cultivation of thinking is particularly important, especially in cultivating self denial, breaking the self, and pulling back scattered thinking. Then, the design of the PCB circuit must be rigorous. Every step and every logic deduction must be impeccable. There are no gaps and can stand scrutiny. When we finish the PCB circuit design of a module, each step and each link, we should review it, whether the deductive function can be realized, what happens when an accident occurs, and how to make up for it. Develop a good habit to make the designed PCB circuit more impeccable.

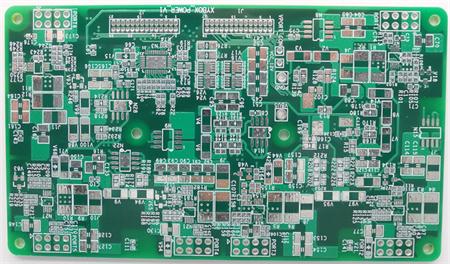

11. Don't think about design from a single angle, but overall planning

In the design, it is not allowed to drag the components and parts to draw directly at the beginning. Such design lacks systematicness and overall planning. Therefore, when designing, we need to have a global view, and then design each detail. When designing, we also need theory as a guide.