Test method for low-temperature embrittlement and lead-free soldering of solders for circuit boards

All kinds of PCB solder alloys widely used in the electronics industry are mainly tin metal, while the traditional solder is rich in eutectic tin lead, so we still take tin lead as an example to review. The main properties of tin lead are shown in the attached table.

Different elements may have characteristic changes due to external temperature, pressure and other conditions. This phenomenon of element changes is called allotropy, which is mainly due to different atomic coordination and binding methods and becomes an alternative monomer. Oxygen and ozone, stone mill and diamond, a-Fe and r-Fe and Fe, and various states of sulfur are typical examples of allotropes

Tin also has two allotropes, a-Sn and B-Sn. Tin is soft and ductile at room temperature, so it is called white tin (B-Sn) in metallurgy. However, if B-Sri is in low temperature, it will produce allotropy changes and become extremely brittle gray tin (a-Sn). The crystal structures of B-Sri and a-Sn are shown in the figure. The changes between them will indeed make the metal more brittle.

Change of inspection methods for lead-free soldering of circuit boards

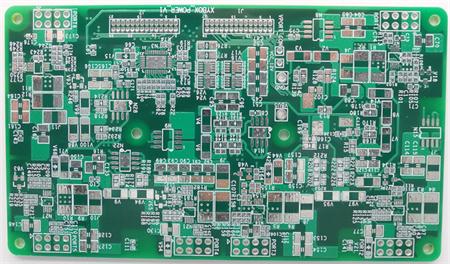

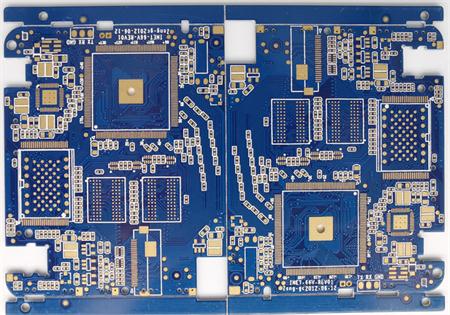

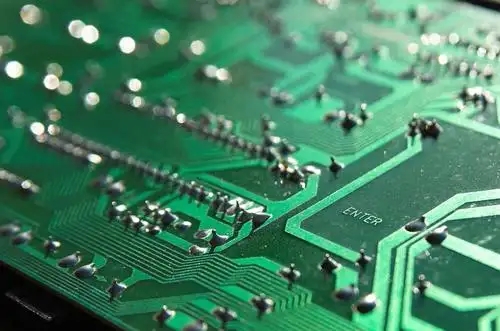

Most circuit board manufacturers currently use IPC specifications to check tin lead contacts, and these basic characteristic states should not be changed too much due to conversion to lead-free systems. The solder climbing height and hole filling are basically maintained at the original level, while the coverage of the Soldering Pad is slightly modified. Most assembly plants do not seem to have much change in the standards of appearance inspection, so comprehensive re learning may not be necessary. As shown in the figure below, it is a typical pin welding result. Different solder compositions do have some differences, but the main structural differences do not seem to come from solder composition.

At the beginning of lead-free assembly, it is necessary to increase the monitoring in the manufacturing process. It will be helpful to improve the technology to compare the yield with the same industry of circuit boards and understand the differences.

Adoption of X-ray inspection

Basically, there is no evidence that the use of lead-free materials will have a negative impact on x-ray inspection. With the experience of most equipment manufacturers, they have good defect detection ability for different lead-free alloy composition detection. The following figure shows the typical solder ball x - 「 ay detection equipment and detection results.

The circuit board manufacturer and circuit board designer explain why the soldering tin of the circuit board becomes brittle at low temperature and the inspection method of lead-free soldering changes.