Anti interference Design of High Speed PCB Based on DSP for PCB Proofing

Analysis on Interference Generation of PCB Proofing 1 DSP System In order to make a stable and reliable DSP system, interference must be eliminated from all aspects, even if it cannot be completely eliminated, it must be minimized. For DSP system, the main interference comes from the following aspects:

① Input and output channel interference. It means that the interference enters the system through the forward channel and the backward channel, such as the data acquisition link of the DSP system. The interference is superimposed on the signal through the sensor to increase the error of data acquisition. In the output link, the interference can increase the output data error, or even make a complete error, causing the system to collapse. Optocoupler devices can be reasonably used to reduce the interference of input and output channels. For the interference of sensors and DSP main system, electrical isolation can be used to input positive interference.

② Interference of power supply system. The main interference source of the whole DSP system. The power supply not only provides power to the system, but also adds its noise to the power supply. The power line must be decoupled when the power chip circuit is designed.

③ Space radiation coupling interference. The radiated coupling is often referred to as crosstalk. Crosstalk occurs in the electromagnetic field generated when the current flows through the wire, and the electromagnetic field induces transient current in the adjacent wire, causing adjacent signal distortion, or even error. The strength of crosstalk depends on the geometric dimensions and spacing of devices and wires. In DSP wiring, the greater the distance between signal lines and the closer to the ground wire, the more effective the crosstalk can be reduced.

2 Design PCB according to the cause of interference. The following is how to reduce various interference methods in the PCB manufacturing process of DSP system.

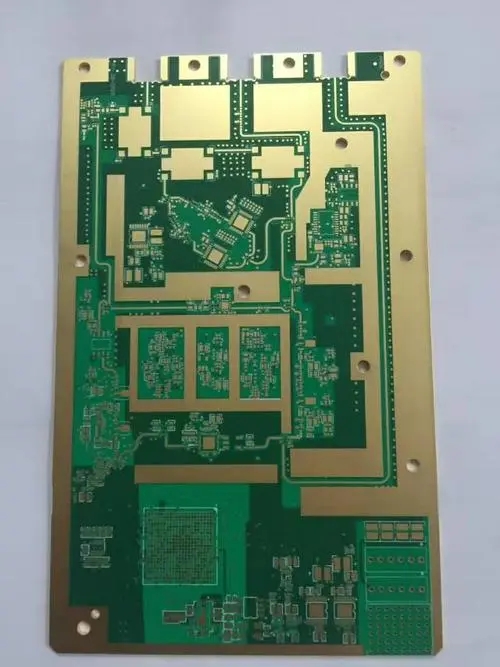

In order to improve the signal quality, reduce the difficulty of wiring, and increase the EMC of the system, the laminated design of multilayer boards is generally used in DSP high-speed digital circuits. The cascade design can provide the shortest return path, reduce the coupling area and suppress differential mode interference. In the cascading design, special power layer and stratum are allocated, and the tight coupling of stratum and power layer is beneficial to the suppression of common mode interference (using adjacent planes to reduce the AC impedance of power plane). Take the 4-layer plate shown in Figure 1 as an example to illustrate the laminated design scheme. The structure designed with this 4-layer PCB has many advantages. There is a power supply layer below the top layer. The power supply pins of components can be directly connected to the power supply without passing through the ground plane. The key signals are laid on the bottom layer (bottorn layer) to make more space for important signal routing, and the devices should be placed on the same layer as far as possible. If it is not necessary, do not make the board of two-layer parts, which will increase the assembly time and assembly complexity. For example, the top layer, only when the top layer components are too dense, can devices with limited height and low heat generation, such as decoupling capacitors (patches), be placed on the bottom layer. For the DSP system, there may be a large number of lines to be laid, which can be laid in the inner layer by using the cascade design. If traditional through-hole will waste a lot of valuable cabling space, blind/buried via can be used to increase the cabling area.

PCB proofing In the DSP system, decoupling capacitors are placed on each integrated circuit, such as DSP, SRAM, Flash, etc., and added between each power supply and the ground of the chip. Special attention should be paid to that decoupling capacitors should be as close as possible to the power supply end (source) and the part pin (pin) of the IC. Ensure the purity of the current from the power supply end (sotlrce end) and into the IC, and shorten the path of noise as much as possible. When handling capacitors, large vias or multiple vias shall be used, and the connection between vias and capacitors shall be as short and thick as possible. When the two vias are far away, the path is too large, which is bad; The best thing is that the two vias of the decoupling capacitor are as close as possible, so that the noise can reach the ground with the shortest path.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the DSP based high-speed PCB anti-interference design of pcb proofing.