Building 6, Zone 3, Yuekang Road,Bao'an District, Shenzhen, China

+86-13923401642Mon.-Sat.08:00-20:00

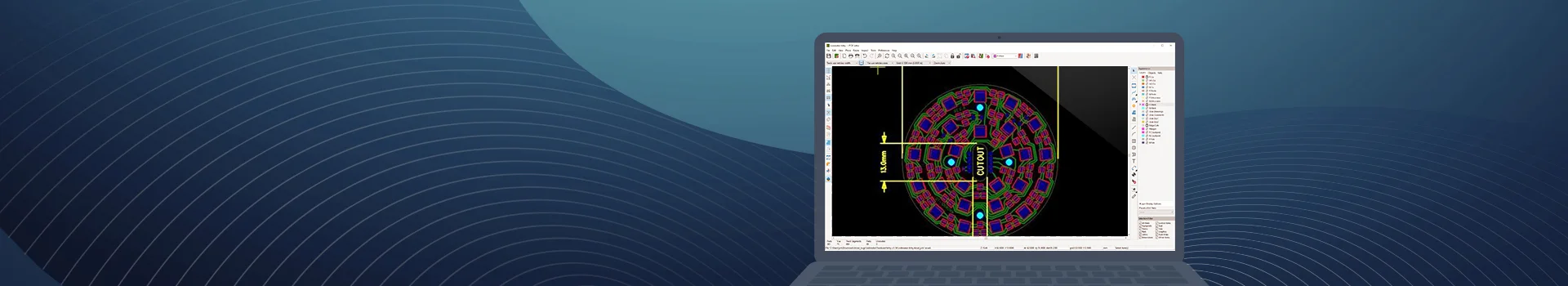

- PCB Design Capabilities

| PCB Design&Layout Capabilities | |||

| Min.trace width: | 2.5mil | Min.trace spacing | 2.5mil |

| Min.Vias: | 6mil(4mil laser drilling) | Max.layer | 48L |

| Min.BGA spacing | 0.35mm | Max.BGA Pin | 3600pin |

| Max.high-speed signal | 40 GBPS | Fastest delivery time | 6 Hours/ Item |

| HDI Highest layer | 22 L | HDI Highest layer | 14 L any layer HDI |

| PCB Design&Layout lead time | |||

| Number of pins on the board | 0-1000 | Design lead time (working days) | 3-5 days |

| 2000-3000 | 5-8 days | ||

| 4000-5000 | 8-12 days | ||

| 6000-7000 | 12-15 days | ||

| 8000-9000 | 15-18 days | ||

| 10000-12000 | 18-20 days | ||

| 13000-15000 | 20-22 days | ||

| 16000-18000 | 22-25 days | ||

| 18000-20000 | 25-30 days | ||

| Ultimate delivery capacity | 10000Pin/7 days | ||

| PS: The above delivery date is the regular delivery date, and the accurate design delivery date needs to be comprehensively evaluated according to the number of components, difficulty, layers and other factors of the circuit board! | |||

Kingford

Why choose us?

Kingford

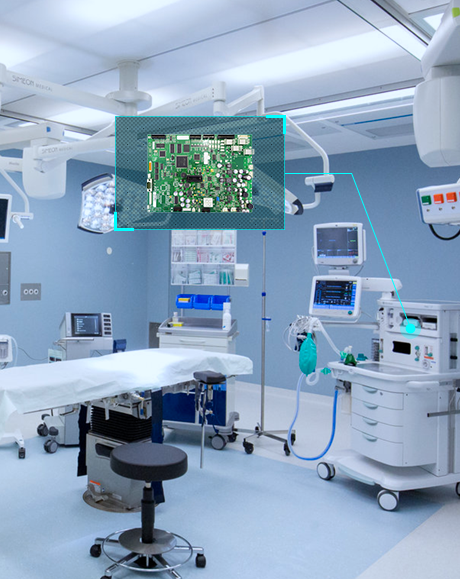

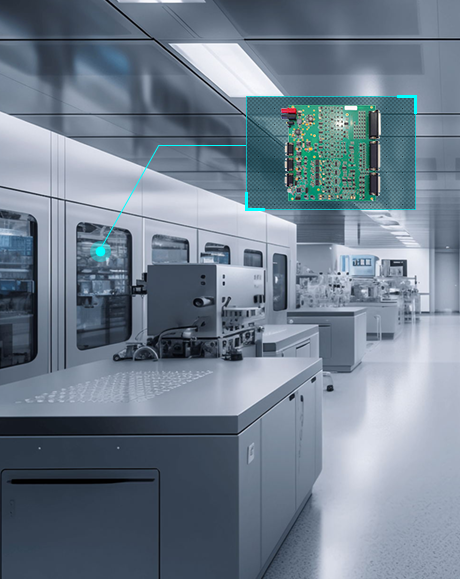

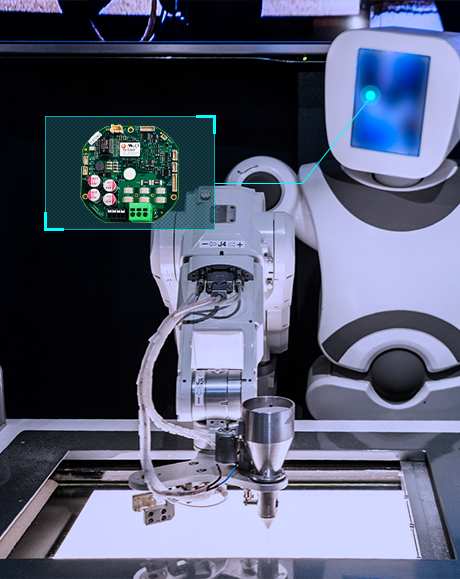

Industries we serve

Kingford

LED PCB Design FAQ

Besides adding lots of LED lights to reduce the temperature of the board, you can use another method. One of the most effective ways to reduce the temperature of LED PCBs is to use aluminum as the substrate.

Reduce power consumption, longer life, more efficient, small size, no mercury, no radio frequency, environmental protection, and cost reduction.

Consumer Lighting, Consumer Electronics, Telecommunications, Transportation, Medical.

Just upload Gerber files, BOM files and design files, and the KINGFORD team will provide a complete quotation within 24h.