What pre-production work should be done for SMT patch processing?

In the field of industrial manufacturing, SMT chip processing is a very common technology. This process can improve the efficiency of circuit board manufacturing, and ensure the quality and stability of the circuit. However, in order to do a good job of SMT patch processing, prior preparation is very important. This article will describe the pre-production preparation required for SMT patch processing so that you can ensure efficient and high-quality production. https://www.kingfordpcb.com/yuan.php?time=1685694568

https://www.kingfordpcb.com/yuan.php?time=1685694568

First of all, to perform SMT patch processing, you need to have a dedicated patch machine. Before you start processing, you need to check the state of the mounter and make sure it can operate properly. Checking the condition of the mounter includes cleaning and inspecting all parts of the equipment. If you find any damaged or worn parts, they must be replaced promptly. This ensures that your mounter is up and running, resulting in increased productivity.

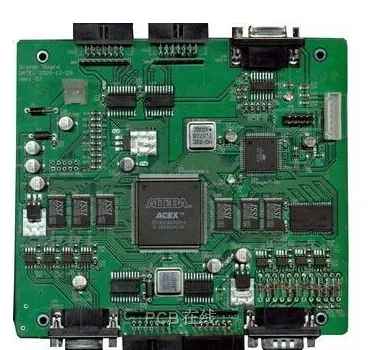

Secondly, before SMT processing, you also need to prepare all the necessary materials and equipment. This includes chip components, circuit boards, solder paste and other auxiliary materials. You should choose good quality materials to ensure the quality and stability of the patch. In addition, you need to make sure that the quantity of all materials is sufficient so that there is no shortage during the production process.

In addition to material and equipment preparation, another key preparation work is to set the parameters of the mounter. These parameters include welding temperature, welding speed and patch accuracy. Selecting the correct parameters can ensure the stability and quality of the mounting process. Here, you should set the parameters according to the different characteristics of the board you want as much as possible. The corresponding parameters can be calculated in advance to ensure production efficiency and patch quality.

Another thing to note is that you need to buy a good circuit board design document, and to understand all the circuit board parts in advance, especially the replacement parts information. Because if some components in production are suddenly no longer produced or supplied, and there are no replacement parts, it is likely to lead to the interruption of production. So in order to avoid this occurrence, it is necessary to make a real judgment on the design document and buy all the parts before processing. This is an important part of ensuring the smooth processing of the patch.

In order to ensure the success of SMT patch processing, you also need to ensure that the production site is clean. Dust in the production environment will affect the accuracy and quality of the patch. Therefore, it is necessary to clean up the production environment, keep the circuit boards and equipment clean, and ensure that operators wash their hands before using the equipment. This ensures the hygiene and quality of the patch processing.

Finally, for SMT chip processing, quality inspection is essential. After finishing the patch, you need to perform a quality check on the board to ensure that all components have been properly installed. The inspection process usually includes appearance inspection and measurement of the electrical characteristics of the components. This ensures the correctness of all components and avoids any failures.

In short, SMT chip processing requires adequate prenatal preparation to ensure efficient and high-quality production. Before processing, you need to check the condition of the chip mounter, prepare all the necessary materials and equipment, set the parameters of the chip mounter, purchase the design documents of the circuit board, keep the production environment clean, and perform quality checks. These operations can ensure the smooth process of SMT patch processing, and ensure the stability and quality of the circuit board.