Step of circuit board factory processing process

Circuit board is an important part of electronic products, plays a role that can not be ignored, the following to introduce the circuit board process production of 12 steps:

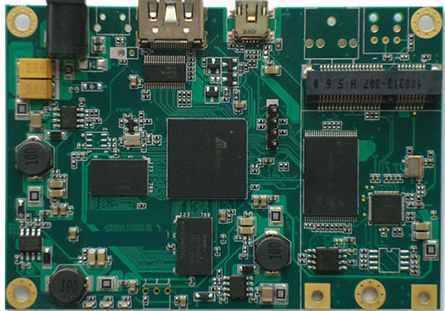

1. Engineering data evaluation: Optimize the engineering data of circuit boards and circuit boards provided by customers, and provide technical support and technical support for the production line.

2. Preparation of opening material: The use of domestic A-grade health benefit plate is the use of mechanical precision cutting, good products start from the source.

3. Drilling: The use of all imported precision high-speed drilling machine, large production area, 8-axis drill at the same time drilling, efficiency and quality at the same time to ensure the auxiliary process to ensure the roughness of the empty wall, convenient post-process production. https://www.kingfordpcb.com/yuan.php?time=1685787379

https://www.kingfordpcb.com/yuan.php?time=1685787379

4. Copper sinking: Automatic copper wire operation, reduce human practice and improve quality stability, professional operators to input I concentration real-time monitoring to ensure production.

5. Graphic transfer: imported film pressing machine and dry film production, pin pin alignment, to ensure the line diameter level line distance.

6. Electroplating: Using chemical production, thickening hole copper level surface copper to ensure the optimal electrical performance of pcb board.

7. AOI optical inspection: quality inspection before candle engraving, to ensure a pass rate, the use of foreign famous imported equipment.

8. Converted the original documents from customers to film negatives, and packaged them after inspection to prepare for the transfer of graphics in the later process.

9. Text: Automatic text screen printing machine is adopted to ensure the clarity and three-dimensional sense of text,convenient SMT welding.

10. Surface treatment: Runze Wuzhou factory mainly has several materials such as spray tin (lead and lead-free), gold plating, gold sinking, antioxidant, tin sinking, silver sinking, rosin, nickel sinking, bare copper and chemical plate.

11. Molding: The introduction of high precision computer numerical control CNC, to ensure the PCB board appearance size tolerance level beautiful, while improving production efficiency.

12. Flying needle test: This is the end of the production line. All use high-speed flying needle test machine special test rack test machine. High-speed test machine is also the equipment equipped by most pcb manufacturers at present. The starting price is expensive, and the efficiency of nitrogen detection is beyond the reach of ordinary equipment.

The above is about the "circuit board factory processing process steps" introduction, I hope to have some help to you, more PCBA information please pay attention to the content of this site updates! kinhford Electronic Technology Co., Ltd. is a professional PCBA processingenterprise, with fully automatic SMT production line and wave soldering, for you to open the whole production and quality testing process, find us, you belong to have your own electronic processing plant!