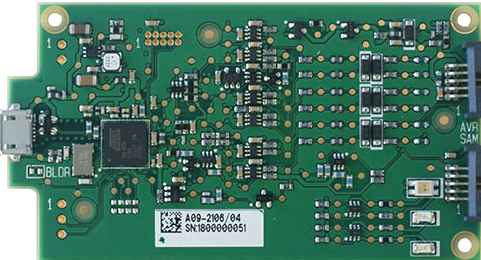

Inspection test and special process of PCBA

PCBA manufacturers need to go through a series of tests before finishing the processing and shipping of PCB SMT patches. They usually carry out functional tests and online tests, which have complementary characteristics. Runze Wuzhou's tests are strictly conducted in accordance with customer quality requirements.

1. Functional test: Test the function of PCBA. If there is any display, the test tool verifies that the test command displays correct information on the screen.

2. Online testing: This kind of testing can check the defects of components in SMT processing.

I. Test method:

ICT: It is a way of testing all components simultaneously and can be done in a few seconds

Flying needle: The test lasts about 30 minutes. All components are tested with flying needles. The machine is programmed according to the layout of the circuit board to test each component

Two, special process:

1. After inspection and testing, the circuit board can be treated with special treatment, such as conformal coating, which is used to protect the PCBA in wet environment.

2. In the case of penetrating components, wave soldering and selective welding can be used to effectively improve the penetration rate of solder joints.

In the process of PCB board assembling, the most important thing to pay attention to is the problem of cutting PCB patch after processing. Due to the reason of production cost, many PCB manufacturers adopt manual board parting, resulting in the increase of labor cost. Nowadays, the electronic products on the market have higher and higher requirements on the volume and size. The thinner PCB is, the easier it is to deform after being subjected to external force. If there are too many pieces of board, the whole area of the board will become very wide. https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

2, three anti-paint coating

Three anti-paint coating is the last link of SMT patch. If there is no mistake in the previous welding and testing assembly, we can ship after this process is completed. Manual coating and machine spraying are two common three anti paint coating methods, manual coating is suitable for small batch, random, machine coating for large quantities, mainly in accordance with the preset program spraying, can effectively prevent the quality of the poor due to artificial mistakes.

The above is about the "PCBA inspection test and special process" introduction, hope to have some help to you, more PCBA information please pay attention to the content of the site update! kinhford Co., Ltd. is a professional PCBA processing enterprise, with fully automatic SMT production line and wave soldering, for you to open the whole production and quality testing process, find us, you belong to have your own electronic processing plant!