SMT is the most detailed process

SMT patch processing is a very complex process, including a lot of technical processes, need to work carefully, otherwise there will be bad products, let kinhford Electronic Technology Co., Ltd. to introduce the SMT patch process in the most detailed process:

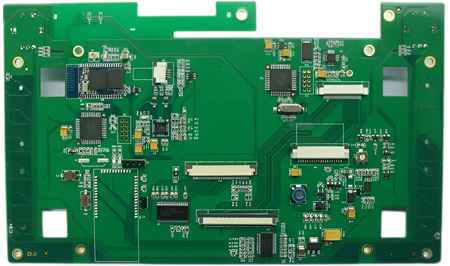

1. PCB Mosaic board

In the process of PCB board assembling, the most important thing to pay attention to is the problem of cutting PCB patch after processing. Due to the reason of production cost, many PCB manufacturers adopt manual board parting, resulting in the increase of labor cost. Nowadays, the electronic products on the market have higher and higher requirements on the volume and size. The thinner PCB is, the easier it is to deform after being subjected to external force. If there are too many pieces of board, the whole area of the board will become very wide.

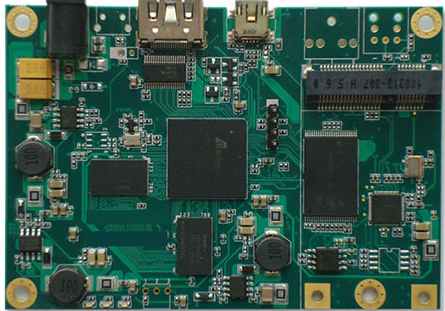

2, three anti-paint coating

Three anti-paint coating is the last link of SMT patch. If there is no mistake in the previous welding and testing assembly, we can ship after this process is completed. Manual coating and machine spraying are two common three anti paint coating methods, manual coating is suitable for small batch, random, machine coating for large quantities, mainly in accordance with the preset program spraying, can effectively prevent the quality of the poor due to artificial mistakes.

Viscosity change: three anti paint before and after use will have different viscosity changes, the higher the temperature of the three anti paint test flow rate is faster;

2, coating thickness: if you want to get a thicker coating, by coating two layers of thin coating to obtain, and must be in the first layer of completely cured before allowed to coat the second layer;

https://www.kingfordpcb.com/yuan.php?time=16856945683, the thickness of the film layer: the addition of diluent is large, the viscosity of the glue is low, the thickness of the glue is thin;

4, inconvenient coating area: connectors, switches, radiators, etc., are not allowed to have coating materials, it is recommended to use tear welding proof CS5001 cover;

5. Temperature and humidity: All coating operations shall be carried out under the condition that the temperature is not lower than 16℃ and the relative humidity is not higher than 75%.

6, coating repair method: if you want to repair the coated device, just the welding iron directly contact the coating can remove the component, install the new component, and then the area with a brush or solvent [thinner] clean, and then dry, and then with three anti-paint coating can be; The above is about the "SMT patch process in the most detailed process" introduction, I hope to have some help to you, more PCBA information please pay attention to the content of the site update! kinhford Electronic Technology Co., Ltd. is a professional PCBA processing enterprise, with fully automatic SMT production line and wave soldering, for you to open the whole production and quality testing process, find us, you belong to have your own electronic processing plant!