There are many kinds of PCB substrates, but they are generally divided into two categories, namely inorganic substrate materials and organic substrate materials.

Inorganic substrate materials

Inorganic base plate is mainly ceramic board, ceramic subgrade board material is 96% alumina, in the case of high strength of the required substrate, can use 99% pure alumina material but high purity alumina processing is difficult, low yield, so the use of pure alumina price is high. Beryllium oxide is also the material of ceramic substrate, it is a metal oxide, has good electrical insulation properties and excellent thermal conductivity, can be used as the substrate of high power density circuits.

Ceramic subgrade board is mainly used in thick and thin film hybrid integrated circuit, multi-chip microassembly circuit, it has the advantages that organic material subgrade board can not compare. For example, the CTE of the ceramic circuit board can be matched to the CTE of the LCCC housing, so that good solder joint reliability can be obtained when assembling the LCCC components. In addition, even when heated, ceramic substrate will not release a large amount of absorbed gas resulting in a decrease in vacuum degree, so it is suitable for vacuum evaporation process in the process of chip manufacturing. In addition, ceramic substrate has the characteristics of high temperature resistance, good surface finish and high chemical stability. It is the preferred subgrade board for thick and thin film hybrid circuits and multi-chip microassembled circuits. However, it is difficult to process into a large and flat substrate, and can not be made into a plurality of stamps together to meet the needs of automatic production. In addition, because of the large dielectric constant of ceramic material, it is not suitable for high-speed electric subgrade board, and the price is relatively high.

Organic substrate materials

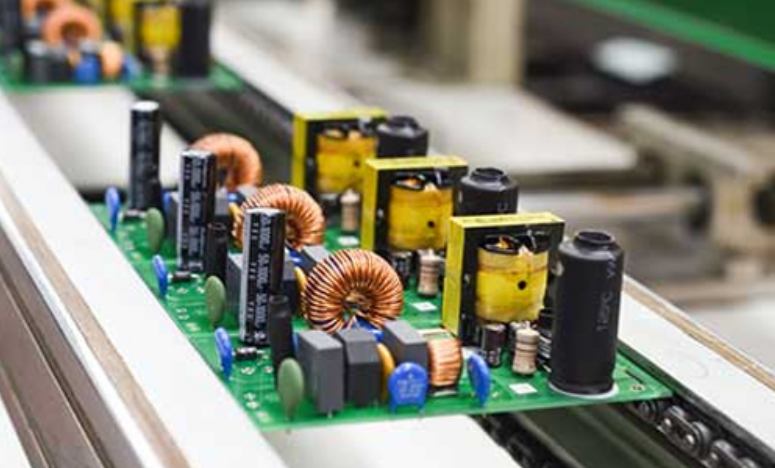

Organic substrate material refers to the reinforcement material such as glass fiber cloth (fiber paper, glass felt, etc.), soaked with resin binder, dried into blank, and then covered with copper foil, and made by high temperature and high pressure. This type of substrate is called copper clad laminate (CCL), commonly known as copper clad, is the main material in the manufacture of PCBS.

There are many kinds of CCL, which can be divided into paper base, glass fiber cloth base, composite base (CEM) and metal base according to the kinds of reinforcement materials used. According to the use of organic resin binder to divide, and can be divided into phenolic resin (PE) epoxy resin (EP), polyimide resin (PI), polytetrafluoroethylene resin (TF) and polyphenyl ether resin (PPO); If according to the hardness and flexibility of the substrate, it can be divided into rigid CCL and flexible CCL

At present, epoxy glass fiber roadbed board is widely used to make double-sided PCB. It combines the advantages of good strength of glass fiber and good toughness of epoxy resin, and has good strength and ductility.

In the manufacture of epoxy glass fiber roadbed board, the epoxy resin is first penetrated into the glass fiber cloth to make laminates. At the same time, also add other chemicals, such as curing agent, stabilizer, flame retardant, adhesive and so on. The copper foil is then glued on one or both sides of the laminate to form a copper-coated epoxy glass fiber laminate. It can be used to produce a variety of single - sided, double - sided and multi - layer PCB.