Key points for implementation of SMT factory cleaning

How to clean the SMT factory?

Definition of cleaning: completely remove garbage, dust and stains.

Cleaning purpose: keep a good mood, stabilize product quality and reduce equipment failures.

(1) Thorough cleaning

Dirty and chaotic workplaces will lead to new equipment failures, unstable product quality, and low morale among employees. Therefore, you must make a decision to thoroughly clean up. Thorough cleaning should first be clean and spotless, and secondly, no matter you can't see, you should work hard to do a good job. Cleaning looks simple, but it's not easy to get it done. This requires meticulous attitude and perseverance. We must formulate countermeasures to solve the difficulties and sources of cleaning work. The so-called difficulties refer to problems that are difficult to solve due to factors such as high position, long working hours, and the need for help and investment from others. Source refers to the place where pollutants pollute the environment and equipment, including liquid, dust, irritant gas and noise sources. To deal with the difficulties and the root causes, we need to make full use of the team spirit and creativity of employees. By analyzing the cause of the problem, take reasonable improvement measures to eliminate the source of the occurrence, or minimize the occurrence, or limit the pollution to the smallest possible range, and keep the environment and equipment clean.

How to clean SMT processing plant?

(2) Cleaning and inspection

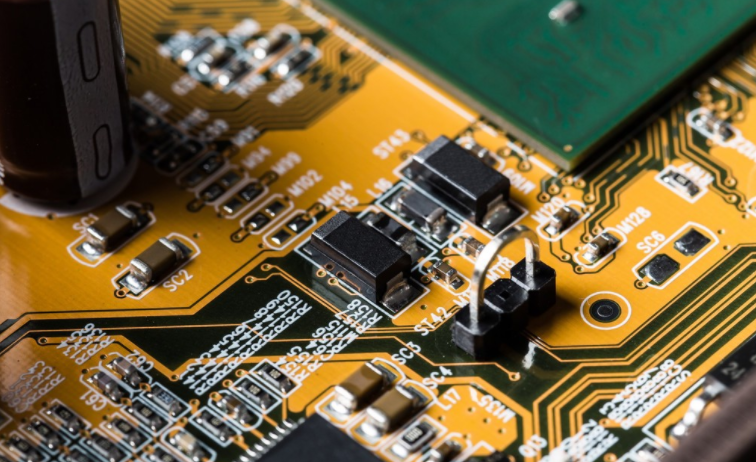

Circuit board

Inspection refers to the inspection and maintenance of equipment. Conditional companies can implement the concept of "cleaning inspection" in 5S activities. The cleaning of the equipment itself is the maintenance of the equipment. Dust, dirt and foreign matters are the causes of equipment deterioration and equipment failure. Only cleaning the equipment can eliminate the adverse effects of dust, dirt and foreign matters on the equipment. Keeping equipment clean is the basic work of equipment maintenance. If you can't clean the equipment, you can't expect a high level of equipment management.

The cleaning process of the equipment is an opportunity to inspect the equipment and eliminate the hidden danger of the equipment. Equipment failures are usually caused by failure to find and eliminate small hidden dangers in time, which is becoming more and more serious. Through thorough cleaning of the surface and interior of the equipment, it is possible to find hidden dangers of the equipment in a timely manner, such as oil leakage, vibration, abnormal noise, cracks, discoloration, excessive temperature, loose screws, and falling solder joints. Timely handling of these hidden dangers is very important to avoid failures and maintain a good operating state of the equipment.

What are the key points of how to clean the SMT patch factory

It is the practice of enterprises that the maintenance of equipment is carried out by professional scientific and technical personnel, and the equipment user is responsible for cleaning the equipment. In order to implement the concept of "cleaning and inspection", it is necessary to let equipment users undertake part of the equipment maintenance work (not all maintenance work of course), so that equipment users have the opportunity to achieve "self-protection", that is, to maintain their own equipment. Users of equipment online maintain their own equipment, which can enhance their sense of responsibility for the equipment. At the same time, because users are together with the device day and night, they know the characteristics of the device best and have the opportunity to find and eliminate hidden dangers in time. In this way, equipment users can play an irreplaceable role in equipment maintenance for professionals. In order to enable users to maintain the equipment themselves, they must become familiar with the equipment. This requires necessary training for users so that they can understand the working principle of the equipment and have basic mechanical and electrical knowledge.

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.