What are the three proofing adhesives for PCB boards and what are their functions?

PCB manufacturers, PCB designers and PCBA manufacturers explain to you what the three proofing adhesives are for PCB boards, and what is their role?

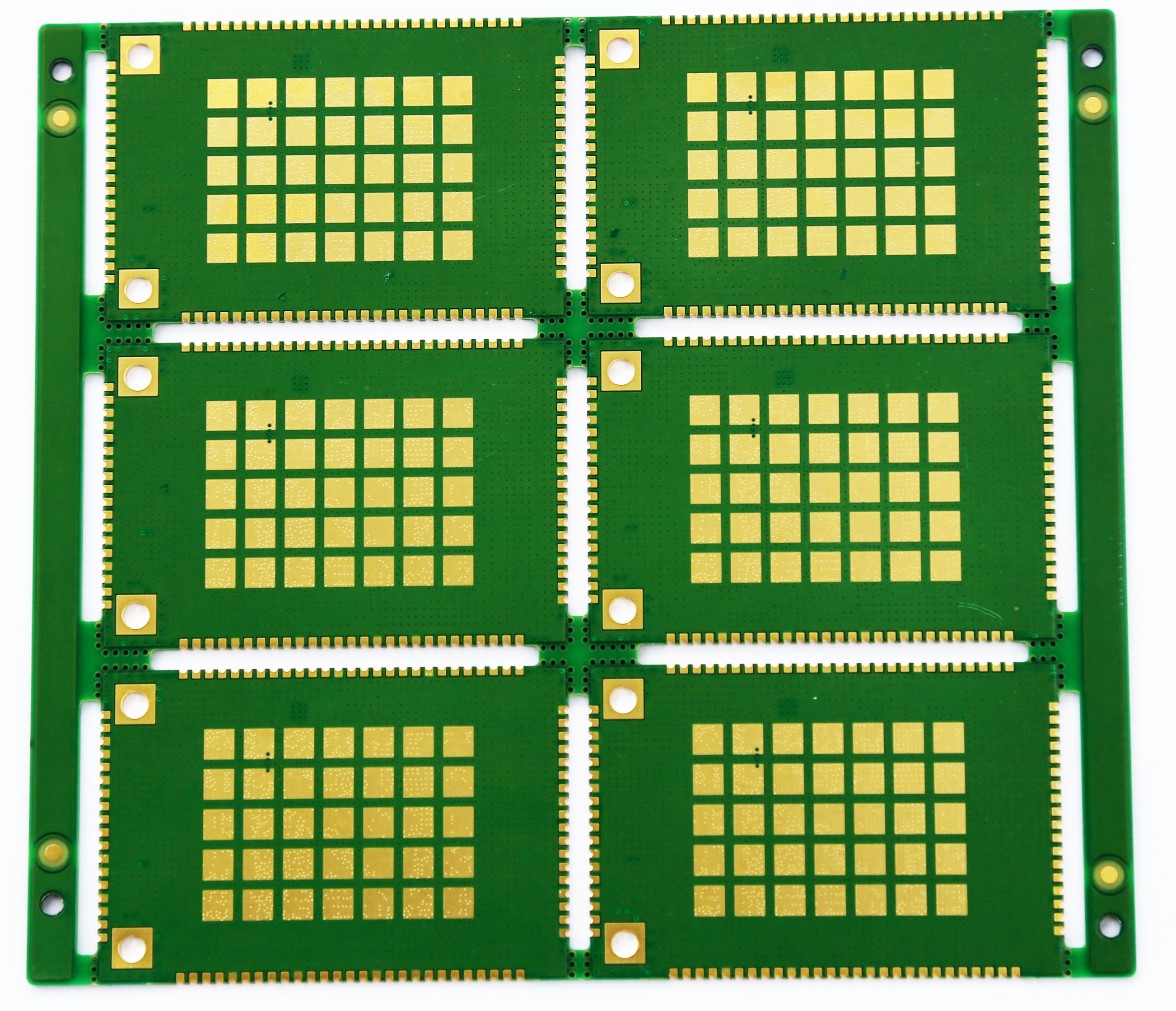

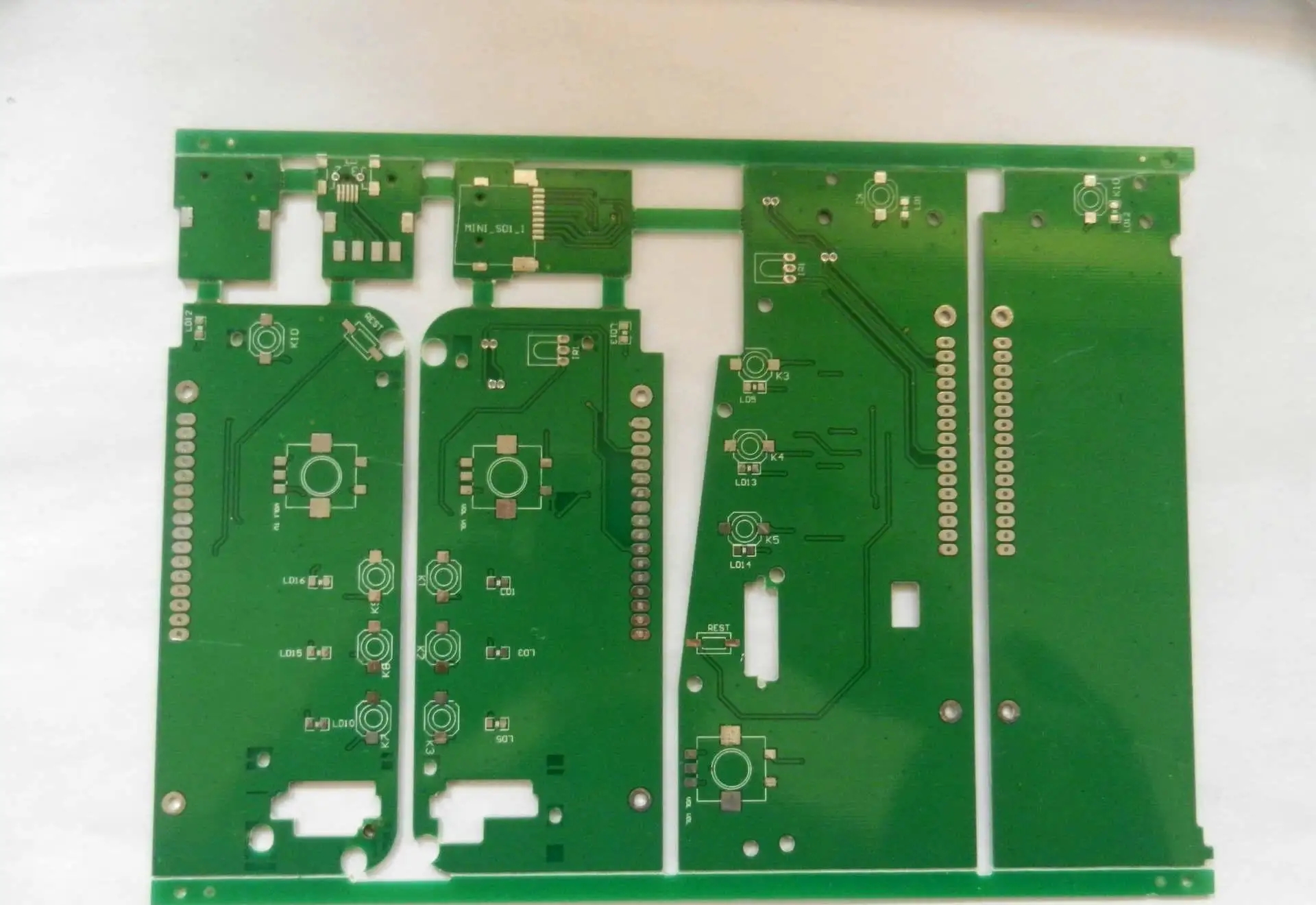

The so-called PCB refers to the printed circuit board, also known as the printed circuit board, which is the provider of electrical connection of electronic components and the mother of electronic elements. It is very common in the electronic industry, and the three proofing adhesive is also widely used. There is no such adhesive as the three proofing adhesive for PCB board. In fact, a layer of three proofing adhesive is applied on PCB. Today, a small editor of PCB board will come to talk with you carefully!

1、 Factors easily causing PCB board damage

Moisture is the most common and destructive factor to PCB. Excessive moisture will greatly reduce the insulation resistance between conductors, accelerate high-speed decomposition, reduce Q value, and corrode conductors. It is often the case that the metal part of PCB board turns copper green, which is caused by the chemical reaction of metal copper with water vapor and oxygen.

2、 Why should PCB board be coated with three proofing adhesive?

Because PCB boards that have used three proofing adhesives not only have the "three proofing" performance of waterproof, moisture-proof and dust-proof, but also have the performance of cold and hot shock resistance, aging resistance, radiation resistance, salt fog resistance, ozone corrosion resistance, vibration resistance, good flexibility and strong adhesion.

When the three proofing adhesive is applied to PCB boards and parts, it can reduce or eliminate the deterioration of electronic operation performance when affected by adverse factors of the operating environment.

Due to the different application environments of different end products, the performance requirements of three proofing adhesives will be emphasized. Refrigerators, washing machines, water heaters and other household appliances have high requirements for moisture resistance, while outdoor fans, street lamps and other products need excellent anti fog performance.

As the "protector" of PCB, the three proofing adhesive is professional. For the purchase of this kind of adhesive product with professional requirements, it is natural to choose a professional and formal brand, and use it with more confidence.

Electronic products are very afraid of being damaged, if they need to be used in harsh environments. It is strongly recommended to coat the PCB with three proofing adhesive, which will form a good protective coating. Moisture proof, corrosion proof and shockproof, with all kinds of protection functions. Now, you know why you should apply the three proofing glue on the PCB. If you need it, don't hurry up! PCB manufacturers, PCB designers and PCBA manufacturers explain to you what the three proofing adhesives are for PCB boards, and what is their role?