Car chips are out of stock, and car PCB are hot? Circuit board factory

PCB manufacturers, PCB designers and PCBA manufacturers explain to you that auto PCBs are hot because of the shortage of auto chips?

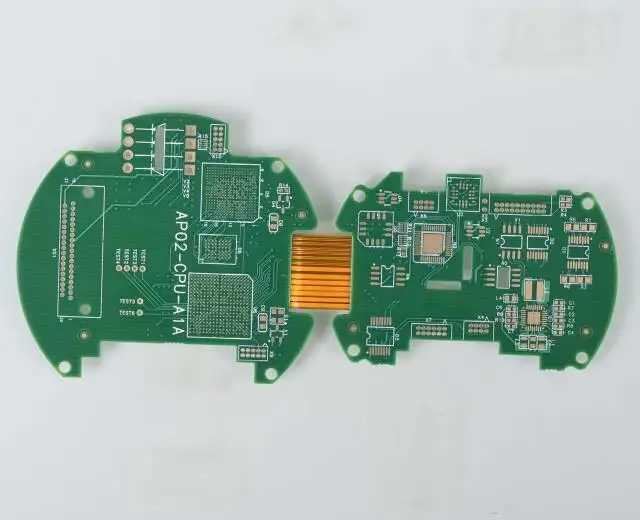

Printed circuit boards, also known as Printed circuit boards, are providers of electrical connections for electronic components.

Printed circuit board is usually represented by "PCB", not "PCB".

PCB design is mainly layout design; The main advantage of using circuit board is to greatly reduce wiring and assembly errors, and improve the automation level and production labor rate.

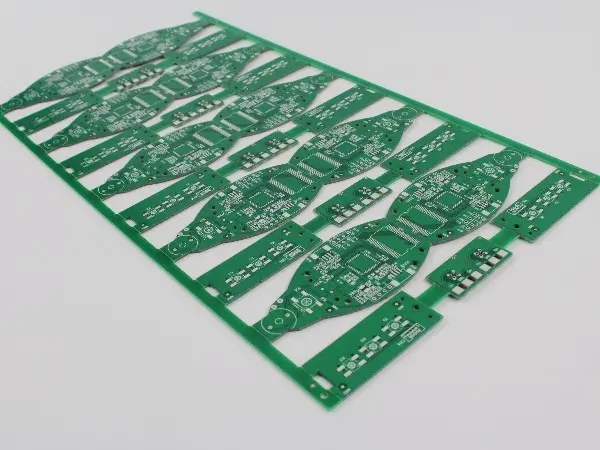

Printed circuit board can be divided into single panel, double panel, four layer board, six layer board and other multi-layer circuit boards according to the number of circuit board layers.

As PCB is not a general terminal product, the definition of its name is slightly confused. For example, the motherboard for personal computers is called the motherboard, but not the circuit board. Although there are circuit boards in the motherboard, they are not the same. Therefore, when evaluating the industry, they cannot be said to be the same. Another example: because there are integrated circuit parts loaded on the circuit board, the news media call it IC board, but in fact it is not the same as printed circuit board. The printed circuit board we usually refer to the bare board - that is, the circuit board without upper element devices.

The shortage of automotive chips has become a hot topic recently. Both the United States and Germany hope that the supply chain will increase the output of automotive chips. In fact, in the case of limited capacity, it is almost impossible to urgently strive for chip capacity unless a good price is offered that is hard to refuse. Even the market has expected that the long-term shortage of car chips will become the norm, and recently it has been reported that some car factories have stopped working.

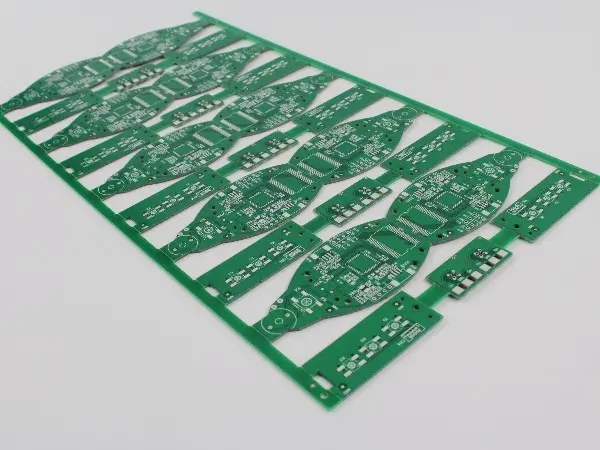

However, whether this will affect other vehicle components is also worthy of attention. For example, the recent sharp recovery of automotive PCB, in addition to the warming of the car market, the customer's fear of out of stock of various parts and components, thus driving up the inventory, is also a key factor. Now the question is, if the car factory is unable to produce the whole car due to insufficient chips and has to stop work to reduce production, will the component manufacturers still actively pull goods for PCB and establish an adequate inventory level?

Now, the order visibility of automotive PCB for more than one quarter is based on the premise that the car factory will try its best to rush the production in the future. But if the car factory is stuck by the chip and cannot produce, if the premise changes, will the order visibility be repaired again? From the perspective of 3C products, the current situation is similar to the shortage of NB processors or specific components, so that other normally supplied products are forced to adjust the delivery rhythm.

It can be seen that the impact of chip out of stock is indeed a double-sided sword. Although customers are more willing to increase the inventory level of each component, as long as the out of stock situation reaches a certain critical point, it may cause the entire supply chain to stop. If the terminal car factory is forced to stop, it will undoubtedly be a major warning.

The automotive PCB manufacturer said frankly that from years of cooperation experience, automotive PCB has been considered as an application with relatively stable demand fluctuations. However, if there is an emergency, the customer's pace of goods pulling changes greatly. It is not impossible to completely change the original order prospects in a short time.

Even though the market seemed hot before, PCB manufacturers were still cautious. After all, there were too many market variables and subsequent development was unpredictable. At present, PCB manufacturers carefully observe the follow-up actions of terminal car manufacturers and major customers, and make corresponding preparations before market conditions change as much as possible.

PCB manufacturers, PCB designers and PCBA manufacturers explain to you that auto PCBs are hot because of the shortage of auto chips?