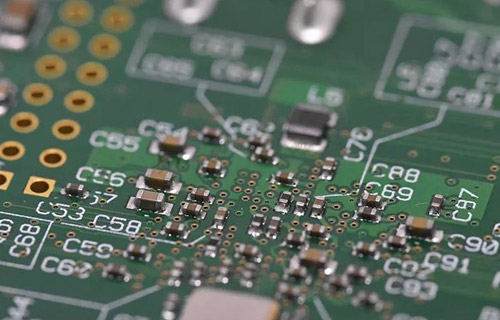

PCB proofing integrated circuit

A New Power Rule Driven PCB Proofing: Interconnection Synthesis

Interconnection synthesis is a typical term for the real-time electrical rule-driven method. That is, in the process of physical layout and routing, the interconnection synthesizer performs real-time analysis according to the constraints of power rules, and selects the routing strategies that meet the requirements of the designer, making the design a success This method accurately integrates power demand and physical realization through interconnection and synthesis, and fundamentally eliminates the defects of physical rule driven method

Pcb proofing

Integrated process PCB verification interconnection is as follows:

Input noise constraints and timing constraints rules in the tool;

Timing control layout to meet timing constraint requirements;

Perform signal integrity pre-optimization;

Board-level integration to ensure that the critical line network meets electrical requirements;

Complete the wiring of ordinary wire netting;

Comprehensive optimization of wiring.

The power rule driven method can effectively evaluate the quality, detect signal distortion, and determine the matching network topology and appropriate terminal matching structure and resistance before designing the layout After the layout is completed, post verification can be carried out, and the waveform can be visually checked using a software oscilloscope The timing and distortion problems found at this time can be solved through the integrated routing optimization function

PCB proofing gold tool combination and Design Process

Now many EDA manufacturers can provide EDA tools for high-speed system PCB design to help users effectively improve the design quality in this field and shorten the design cycle The most representative of EDA system board level tools using electric power rule driven method is the ICX package software of Mentor Graphics Company in the United States It is the first person to propose the concept of interconnection and integration, and also the most mature tool portfolio in the industry This software package has the current industry popular plug and play function, which can be integrated into many manufacturers' PCB classic EDA design process

PCB Proofing Mixed Signal Design Solution

As design minimization has become fashionable, consumers need high-performance, low-cost products To adapt to market competition, manufacturers require R&D personnel to develop different types and different functional configurations of high performance and low cost products in the shortest possible time Products, occupy the market This has brought many new design challenges to designers For example, using digital analog hybrid technology, or even RF technology, to achieve miniaturization and improve product functions on the same substrate The mobile phones that are popular all over the world are the most typical examples There are also corresponding solution design teams in the industry. Concurrent design, derivation and design reuse are the most typical strategies

PCB proofing traditional serial design

That is, after the electronic engineer completes all the front-end circuit design, it is transferred to the physical board level designer to complete the back-end implementation Design cycle is the sum of circuit design and board level design time After the new concurrent design has become the mainstream design idea and the hybrid technology has been widely used, the tandem design method is somewhat outdated We must innovate in design methods and use powerful EDA tools to assist designers in design, in order to meet the requirements of timely listing As we all know, it is impossible for each of us to become an expert in all fields, or to complete all the work at the best speed in a short time The concept of design team was put forward in this context and has been widely used At present, many companies are using the design team approach to develop products That is to say, according to the complexity of the design and different functional modules, the whole design is divided into different functional blocks, and different designers and developers design logic circuits and PCB boards in parallel; At the top level of the design, the final design results of each block are imported and integrated into the entire circuit board design through the pipeline of "equipment" This method is called PCB design reuse Through this method, it is easy to see that it can greatly shorten the design cycle. The design time is just the sum of the most time-consuming block design time and the back-end interface connection processing time

PCB proofing tool standardization and third part tool integration

At present, there are many manufacturers engaged in the development of electronic design automation (EDA) tools, such as Cadence; In addition, there are many other EDA manufacturers EDA covers a wide range of fields, including networks, communications, computers, aerospace, etc The products involve motherboard design, system digital/IF analog/digital analog hybrid/RF analog design, system integrated circuit/ASIC/FPGA design/analog/verification, software hardware collaborative design, etc It is difficult for any EDA supplier to provide the most powerful design process to meet the different design needs of different users From the perspective of market share, Cadence's powerful products are integrated circuit board design and services, the outlined powerful products are logic synthesis, and Mentor Graphics' powerful products are PCB design deep submicron integrated circuit design verification and testing Undoubtedly, modern electronic design increasingly relies on EDA tools and technologies, and EDA manufacturers adopt product standardization methods to meet the needs of users Many designers use powerful products from multiple companies in the design process to form the best design process Various EDA manufacturers have improved the compatibility of their powerful products and the ability to integrate the products of third-party manufacturers to meet the potential needs of users

PCB Proofing Derivative Technology

Manufacturers focusing on civilian products often need to develop products with different functions and different grades to occupy the market in order to meet the needs of users at different levels. In the past, for the development of products with different functions, we often used different design processes to implement them respectively. That is, we used different design data to produce circuit boards with different functions to realize products The disadvantage is that the cost is increased, the design cycle is extended, and the artificial unreliability of the product is increased Many manufacturers now use derivative technology to solve the above problem. That is, they use the same design process data to export products with different functional families, so as to reduce costs and improve quality To meet the needs of users, many EDA manufacturers have added Derived Rule Check (DRC) functions to their products, such as Mentor Graphics BoardStation, Zuken Redac, etc Taking BoardStation as an example, it provides the distribution of derivative functional modules of a complete front-end circuit design, back-end physical layout rule check, composition list of different derivative products, production and processing data, photo drawing data and processing assembly drawings, etc, Completely ended this PCB design trouble