How to use protel software to design high-speed PCB

In order to continue to improve everyone's PCB design software, this paper will explain how to design a protel based circuit design software for high-speed PCB The significance of circuit design software is to design circuits Without circuit design software, circuit design will become very troublesome This paper will explain how to design the circuit design software based on protel for high-speed PCB

1. Problems

In high-speed circuit design, the inductance and capacitance on the circuit board can make the wire equivalent to the transmission line. Improper placement of terminal components or wrong routing of high-speed signals may lead to transmission line effect problems, resulting in incorrect data output from the system, improper circuit operation, or even no operation at all. Based on the transmission line model, it can be concluded that the transmission line will bring adverse effects to the circuit design, such as signal reflection, crosstalk, electromagnetic interference, power supply and grounding noise. In order to design high-speed PCB boards that can work reliably, we must fully and carefully consider the design to solve some unreliable problems that may occur in the layout and wiring process, shorten the product development cycle, and improve the market competitiveness. This paper discusses some related principles of layout and wiring that should be paid attention to in the process of using PROTEL design software to realize high-speed circuit PCB design, and provides some practical and proven high-speed circuit layout and wiring technologies to improve high-speed circuit boards. Design reliability and validity. The results show that the design shortens the product development cycle and improves the market competitiveness.

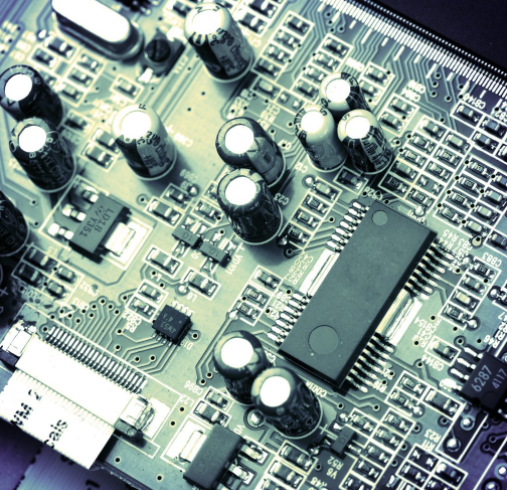

PCB board

2. Layout design of high frequency system

Layout is an important link in PCB design. The quality of layout results will directly affect the routing effect and system reliability, which is time-consuming and difficult in the whole PCB design. The complex environment of high-frequency PCB makes it difficult to use the theoretical knowledge they have learned in the layout design of high-frequency systems. This requires that the layout personnel must have rich experience in high-speed PCB manufacturing to avoid walking around in the design process. And improve the reliability and effectiveness of the circuit. In the layout process, the mechanical structure, heat dissipation, electromagnetic interference, convenience and aesthetics of future wiring shall be comprehensively considered. First, before layout, divide the functions of the whole circuit, separate high-frequency circuit from low-frequency circuit, and separate analog circuit from digital circuit. Avoid the transmission delay caused by long wires and improve the decoupling effect of capacitors. In addition, pay attention to the relative position and direction of pins and circuit components and other tubes to reduce mutual influence. All high-frequency components shall be kept away from chassis and other metal plates to reduce parasitic coupling. Secondly, pay attention to the thermal and electromagnetic effects between components during layout. These effects are particularly serious for high-frequency systems, and measures should be taken to keep them away from or isolate them, dissipate heat and shield them. The high-power rectifier pipe and regulating pipe shall be equipped with radiator and shall be far away from the transformer. The heat-resistant parts such as electrolytic capacitors should be far away from the heating parts, otherwise, the electrolyte will be dry, resulting in new resistance, poor efficiency and affecting the stability of the circuit. There should be enough space in the layout to arrange the protective structure and prevent the introduction of various parasitic coupling. To prevent electromagnetic coupling between coils on the printed circuit board, the two coils should be placed at right angles to reduce the coupling coefficient. Vertical plate isolation method can also be used. Solder the circuit directly with the leads of its components. The shorter the lead, the better. Do not use connectors and pads, because there are distributed capacitors and distributed inductors between adjacent pads. Avoid placing high noise components around crystal oscillators, woods, analog voltage and reference voltage signal traces. While ensuring the inherent quality and reliability, considering the overall aesthetics and reasonable circuit board planning, components should be parallel or perpendicular to the board surface and parallel or perpendicular to the edge of the main board. The distribution of components on the surface of the circuit board shall be as uniform as possible and the density shall be the same. This is not only beautiful, but also easy to install, weld and mass produce.

3. High frequency system wiring

In high frequency circuit, distribution parameters of the resistance, capacitance, inductance and mutual inductance of the connecting line cannot be ignored. From the perspective of anti-interference, reasonable wiring is to minimize the line resistance, distributed capacitance and stray inductance in the circuit, so as to reduce the stray magnetic field generated thereby to a certain extent, thus restraining the distributed capacitance, magnetic flux leakage, electromagnetic mutual inductance and other interference caused by circuit noise. PROTEL design tools are widely used in China. However, many designers only pay attention to the "pass rate" and do not use the improved PROTEL design tool to adapt to the changes in equipment characteristics in the design, which not only causes serious waste of design tool resources, but also makes it difficult to play the excellent performance of many new equipment. The following describes some special functions that can be provided by PROTEL99 SE tool.

1) The leads between the pins of high-frequency circuit components should be bent as little as possible. Use full lines. When bending is required, a 45 ° fold line or arc can be used for bending, which can reduce the external emission and mutual coupling of high-frequency signals. When using PROTEL routing, select 45 degrees or fillets in Rules on the Design menu. You can also use the shift+blank key to quickly switch between lines.

2) The shorter the lead between the pins of high-frequency circuit components, the better. An effective way for PROTEL 99 to meet the requirements of short wiring is to reserve wiring for each key high-speed network before automatic wiring. Select the shortest path in Routing Topology under Rules in the Design menu.

3) The less alternating between lead layers between pins of high-frequency circuit components, the better. In other words, the fewer through holes used in the component connection process, the better. One through-hole can bring 0.5pF distributed capacitance, reducing the number of through-hole can significantly improve the speed.

4) For high frequency circuit wiring, pay attention to the "cross interference" or crosstalk introduced by parallel wiring of signal lines. If parallel distribution cannot be avoided, a large area of "grounding" can be arranged at the opposite side of the parallel signal line to greatly reduce interference. Parallel lines in the same layer are almost inevitable, but in two adjacent layers, the direction of lines must be perpendicular to each other, which is not difficult to achieve in PROTEL, but easy to ignore. In the Routing Layer Design menu Rules, select Horizontal as the top layer and Vertical as the bottom layer. In addition, the "polygon plane" function is provided in "Position", that is, polygonal mesh copper foil surface. If placed, the polygon will be considered as a surface of the entire printed circuit board and the copper will be applied. It is connected to the GND of the circuit, which can improve the high frequency anti-interference capability, and also has great advantages for heat dissipation and PCB strength.

5) For signal lines or local units that are particularly important, earth wire enclosure measures should be implemented. "Contour Selected Objects" is provided in "Tools", which can be used to automatically "ground" selected important signal lines (such as oscillator circuits LT and X1).

6) Usually, the power and ground wires of the circuit are set wider than the signal lines. You can use Category in the Design menu to divide the network into power network and signal network. Combined with the setting of routing rules, it can be easily executed. Line width switching of power line and signal line.

7) No trace can form a loop, nor can the ground wire form a current loop. If a loop is generated, it will cause great interference to the system. In this regard, the daisy chain wiring method can be used, which can effectively avoid the formation of loops, branches or stubs in the wiring process, but also brings about the problem of difficult wiring.

8) According to the data and design of various chips, the current passing through the power line is estimated and the required wire width is determined. According to the empirical formula, we can get: W (line width) L (mm/A) I (A). According to the current, increase the width of the power line as much as possible to reduce the circuit resistance. At the same time, the direction of the power cord and ground wire is consistent with that of the data transmission, which helps to enhance the anti noise capability. If necessary, a high-frequency choke device made of copper wire wound ferrite can be added to the power line and ground wire to block the transmission of high-frequency noise.

9) The wiring width of the same network shall remain the same. The variation of line width will lead to non-uniform characteristic impedance of the line. When the transmission rate is high, reflection will occur, which should be avoided as far as possible in the design. At the same time, the line width of parallel lines is added. When the center distance of the line is not more than 3 times of the line width, 70% of the electric field can be maintained without mutual interference, which is called the 3W principle. In this way, the influence of distributed capacitance and distributed inductance caused by parallel lines can be overcome.

4. Design of power line and ground wire

In order to solve the voltage drop caused by the power noise and line impedance introduced by the high frequency circuit There are usually two solutions: one is to use power bus technology for wiring; The other is to use a separate power layer In contrast, the production process of the latter is more complex and the cost is higher Therefore, network type power bus technology can be used for wiring. Since each component belongs to a different loop, the current on each bus on the network tends to balance, reducing the voltage drop caused by line impedance High frequency transmission power is relatively large. Large area of copper can be used to find a low resistance grounding plane nearby for multi-point grounding Because the inductive reactance of the grounding wire is proportional to the frequency and length, when the operating frequency is high, the common grounding impedance will increase, which will increase the EMI generated by the common ground impedance. Therefore, the length of the grounding wire is required to be as short as possible Minimize the length of signal line and increase the area of grounding loop One or more high-frequency decoupling capacitors are set at the power and ground terminals of the chip to provide a nearby high-frequency channel for the transient current of the integrated chip, so that the current will not pass through the power line with a large loop area, thus greatly reducing the radiated noise It is necessary to choose a monolithic capacitor ceramic capacitor with good high-frequency signal as the decoupling capacitor Use high-capacity tantalum capacitor or polyester capacitor to replace electrolytic capacitor as energy storage capacitor for circuit charging Because the distributed inductance of electrolytic capacitor is very large, it is invalid for high frequency When using electrolytic capacitors, they are used in pairs with decoupling capacitors, and have good high-frequency efficiency PCB characteristics