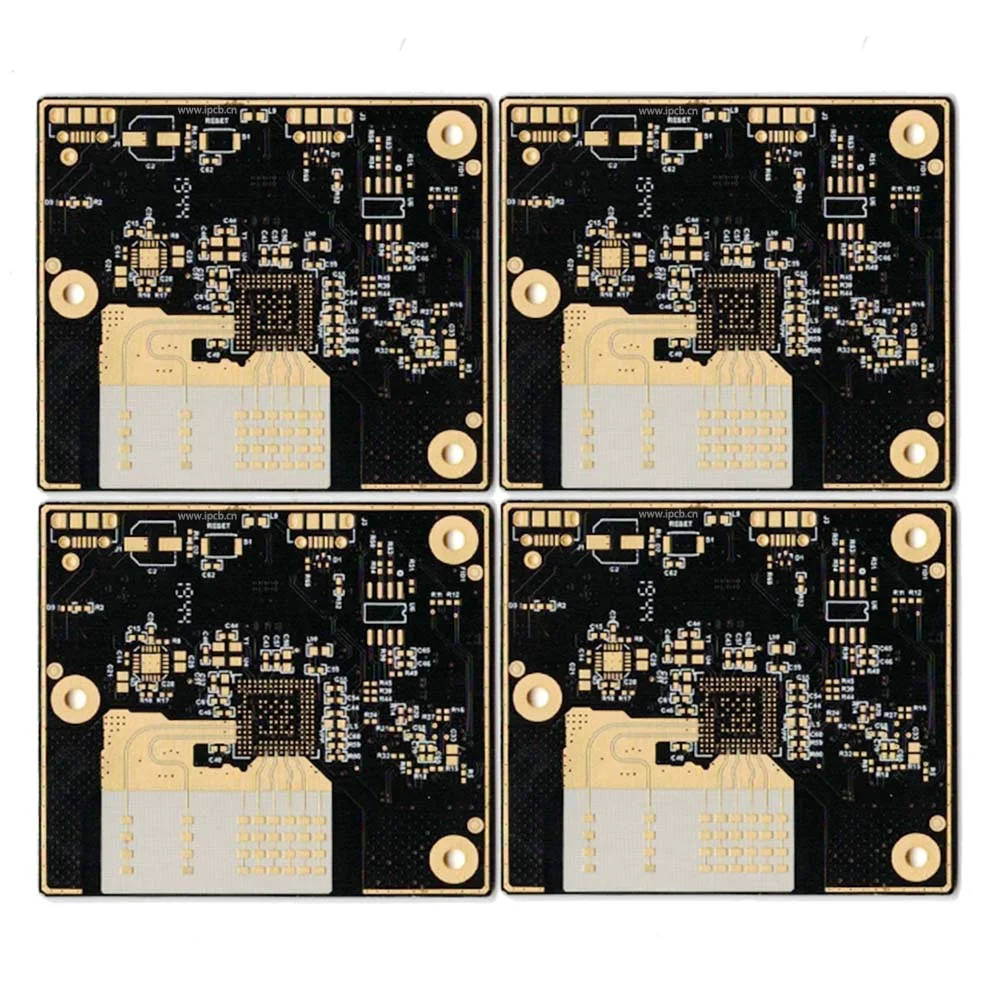

Rogers RO4835 77G millimeter wave radar PCB board

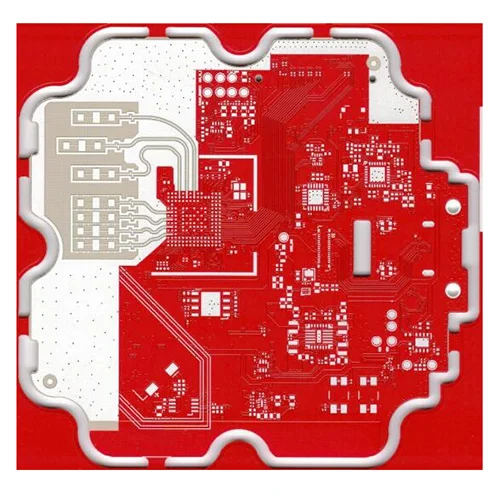

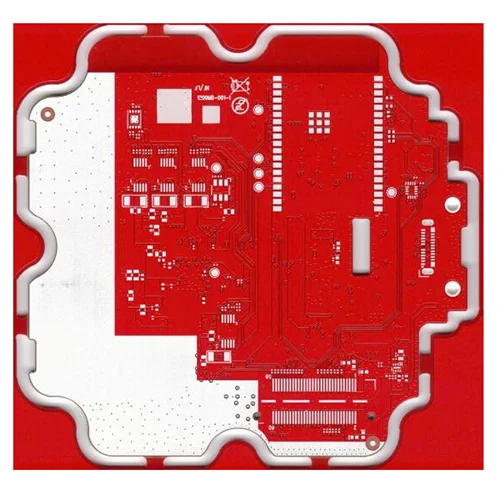

Product name: Rogers RO4835 77G millimeter wave radar board

Plate: Rogers RO4835+FR4

Dielectric constant: high frequency material dielectric constant 3.48

Medium thickness: 4mil (0.1mm)

Layers: 6 layers

Plate thickness: 1.2mm

Copper Thickness: 1oz for inner and outer layers

Via: Resin plug hole

Surface technology: chemical immersion gold

Thermal conductivity: 0.69w/m.k

Loss: 0.003

Line width: 0.1mm

Line distance: 0.1mm

Blind hole structure: L1-L2, L3-L6

Uses: automotive radar, automotive sensor module

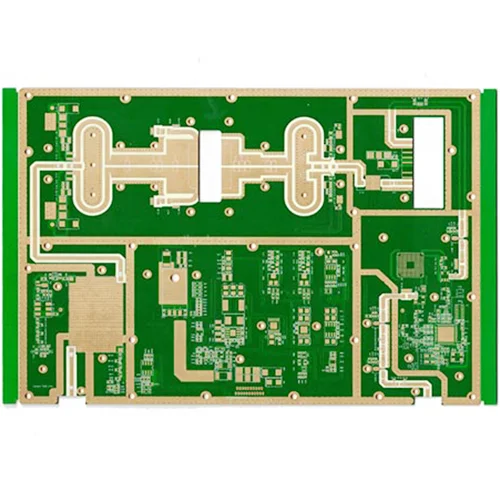

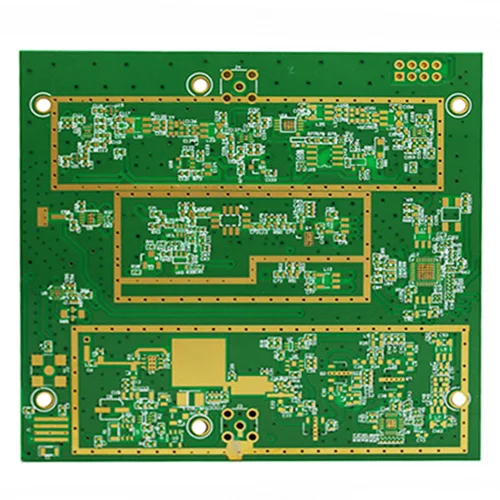

Millimeter-wave radar mainly uses 24G radar PCB and 77G radar PCB, and millimeter-wave radar PCB is mainly used for automotive AI intelligent unmanned driving.

Millimeter wave radar PCB has broad application prospects. At present, iPCB adopts Rogers RO3003G2+ITEQ IT180 to mass-produce 77GHz millimeter-wave radar PCB.

A common feature for different radar PCB designs for mmWave radar sensors is the need for ultra-low loss radar PCB materials to reduce circuit losses and increase antenna radiation. Radar PCB material is a critical component in radar sensor design. Choosing the right radar PCB material can ensure the stability and consistency of the millimeter-wave radar sensor.

How to Design the Performance of a Radar PCB

First, the electrical properties of radar PCB materials are the primary factor in designing radar sensors and selecting radar PCB materials. Selecting radar PCB materials with stable dielectric constant and ultra-low loss is critical to the performance of 77GHz mmWave radar. The stable dielectric constant and loss can make the antenna receive and receive accurate phase, which can improve the gain, scanning angle or range of the antenna, and improve the accuracy of radar detection and positioning. The stability of the dielectric constant and loss characteristics of the PCB not only ensures the stability of different batches of materials, but also ensures that the variation within the same PCB board is small and has good stability.

Product name: Rogers RO4835 77G millimeter wave radar board

Plate: Rogers RO4835+FR4

Dielectric constant: high frequency material dielectric constant 3.48

Medium thickness: 4mil (0.1mm)

Layers: 6 layers

Plate thickness: 1.2mm

Copper Thickness: 1oz for inner and outer layers

Via: Resin plug hole

Surface technology: chemical immersion gold

Thermal conductivity: 0.69w/m.k

Loss: 0.003

Line width: 0.1mm

Line distance: 0.1mm

Blind hole structure: L1-L2, L3-L6

Uses: automotive radar, automotive sensor module