Isola high frequency board

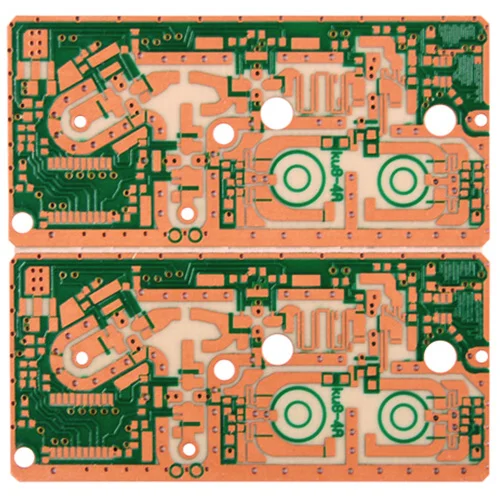

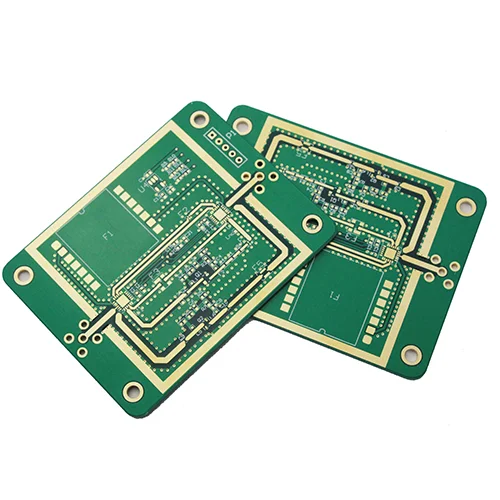

Name: Isola high frequency board

Layers: 4L

Plate thickness: 1.0mm

Plate used: Isola high frequency plate

Size: 76.3mm*69.9mm

Z small aperture: 0.25mm

Dielectric constant: 3.38

Layer: 2L

Substrate thickness: 0.813mm (32mil)

Product thickness: 0.9mm

Copper Plating Thickness: 1 oz (35μm)

Surface Treatment: Immersion Gold

Minimum line width/line spacing: 6mil/6mil

application:

Automotive, Backplane, RF/Microwave, High-End Computing

Signal Integrity, Medical, Military, Mobile Devices/Wireless Handsets

Railroads, Servers, Switches/Routers, Thermal Management, Wireless Infrastructure

What does Isola PCB mean?

Such printed circuit boards are complex and manufactured using high performance laminates. It incorporates resin components designed to meet demanding performance requirements.

This type of PCB is used in most electronic devices, such as aerospace equipment and high-end consumer electronics.

Types of materials used in Isola PCBs

There are materials used to make Isola PCBs. Some of these include

Prepreg

The term is associated with the PCB industry. It's called "pre-dipping". This is a dielectric material that provides electrical insulation as well as other important functions. It is made through a fiberglass fabric infused with a uniquely formulated resin.

The resin combines different thermal, electrical and physical properties with the prepreg. This is important to correct the operation of Isola PCB.

CCL

This consists of a prepreg laminate with a thin layer of copper foil on both ends. This lamination is achieved by compressing one or more layers of copper and prepreg together under extreme heat, pressure and vacuum conditions.

Building Multilayer Isola PCBs

Prepreg and CCL are used to fabricate multilayer Isola PCBs through complex operations involving multiple processes that are often repeated.

The copper surface of the laminate is etched. This is for the production of electronic circuits. Next, the laminates are assembled by inserting one or more layers of prepreg between each etched laminate to form a multilayer structure.

Electroplating and drilling then form electrical interconnects between the PCB layers. The resulting Isola PCB is an interconnect gadget in which semiconductors and other components are mounted.

Isola PCB Applications

Isola PCB's laminates and prepregs are used in different devices and advanced electronics, including:

Aerospace applications

Military electronic applications

Industrial equipment applications

High-end consumer electronics

Network and other communication equipment

Automotive applications

Medical device applications

What materials are used in Isola PCB's resin systems?

Isola PCB uses no-flow prepregs, which are polyimide-based for PCB applications that require high temperatures.

They use a polyimide flame retardant resin system and are ideal for applications requiring superior performance and thermal performance. Isola's prepregs feature polyimide blends and thermoplastic resins that fully cure without the use of methylene diphenylamine (MDA).

This then results in a polymer with a high Tg, which does not have the problems of brittleness and low initial bond strength. Therefore, the resin system of Isola PCB is much better than the resin structure of traditional thermosetting polyimide.

Features of Isola Prepregs

Here are some key features of Isola PCB materials:

Maintains bond strength at elevated temperatures

Halogen-free option available

Higher thermal performance

Reduces delamination due to machining

Enhanced workability due to reduced brittleness

Long service life of resin system

Name: Isola high frequency board

Layers: 4L

Plate thickness: 1.0mm

Plate used: Isola high frequency plate

Size: 76.3mm*69.9mm

Z small aperture: 0.25mm

Dielectric constant: 3.38

Layer: 2L

Substrate thickness: 0.813mm (32mil)

Product thickness: 0.9mm

Copper Plating Thickness: 1 oz (35μm)

Surface Treatment: Immersion Gold

Minimum line width/line spacing: 6mil/6mil