Impedance Controlled PCB Design

Impedance Controlled PCB Design

1 Introduction

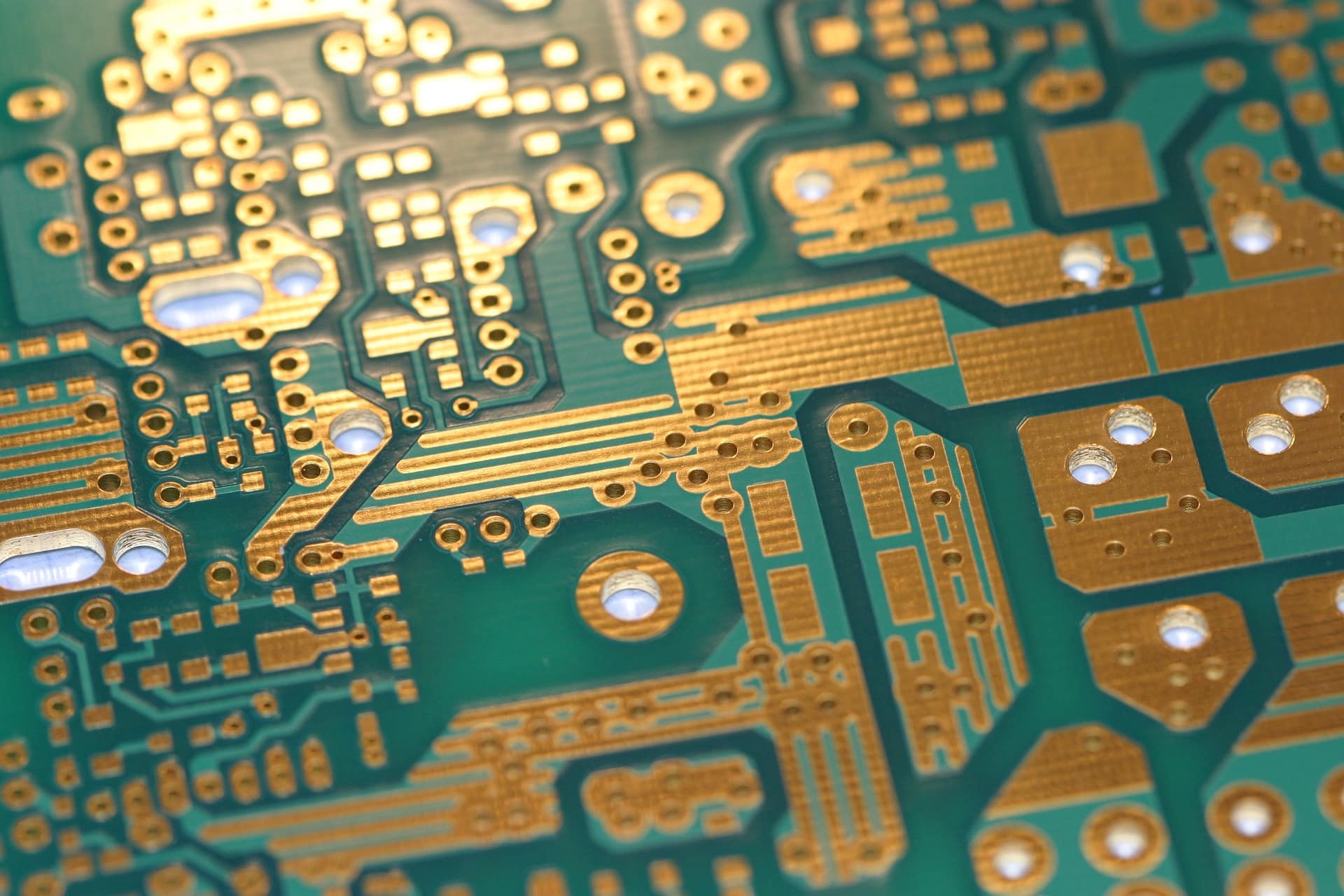

With the development of science and technology, especially in the progress of integrated circuit materials, the calculation speed has been significantly improved, and the integrated circuit has been promoted to high density, small volume, and single component, which will lead to the high frequency response of today's and future printed circuit boards. , The use of high-speed digital circuits, that is, must control the impedance of the line, low distortion, low interference and low crosstalk and eliminate electromagnetic interference EMI. Impedance design is becoming more and more important in PCB design. As the front-end of PCB manufacturing, it is responsible for the simulation calculation of impedance and the design of impedance strips. Customers have increasingly stringent requirements on impedance control, and the number of impedance controls is increasing. How to quickly and accurately design impedance is a problem that pre-production personnel are very concerned about.

2. Main types of impedance and influencing factors

Impedance (Zo) Definition: The total resistance to the alternating current of known frequency flowing through it is called impedance (Zo). For printed circuit boards, it refers to the impedance of a certain circuit layer (signal layer) to the sum of its closest related layers (reference plane) under high-frequency signals.

2.1 Impedance type:

(1) Characteristic impedance In computer, wireless communication and other electronic information products, the energy transmitted in the PCB line is a square wave signal (square wave signal, called pulse pulse) composed of voltage and time. The resistance encountered is called the characteristic impedance.

(2) Differential Impedance The driving end inputs two identical signal waveforms with opposite polarities, which are transmitted by two differential lines respectively, and the two differential signals are subtracted at the receiving end. The differential impedance is the impedance Zdiff between the two lines.

(3) Odd-mode impedance The impedance Zoo of one of the two lines to the ground, the impedance value of the two lines is the same.

(4) Even-mode impedance The driving end inputs two identical signal waveforms with the same polarity, and the impedance Zcom when the two lines are connected together.

(5) Common-mode impedance The impedance Zoe of one line to the ground in the two lines, the impedance value of the two lines is the same, usually larger than the odd-mode impedance.

Among them, characteristic and differential are common impedances, while common mode and odd mode are rare.

2.2 Factors affecting impedance:

W-----Line width/inter-line The impedance becomes smaller as the line width increases, and the impedance increases as the distance increases;

H----Insulation thickness The thickness increases and the impedance increases;

T------copper thickness The impedance becomes smaller as the copper thickness increases;

H1 --- thick green oil, the resistance becomes smaller as the thickness increases;

Er-----dielectric constant reference layer DK value increases, impedance decreases;

Undercut----W1-W When the undercut increases, the impedance becomes larger.

3. Automatic impedance calculation

Today, the most commonly used impedance calculation tool in our industry is Si8000 Field Solver provided by Polar. Si8000 is a brand new boundary element method field effect solution calculator software, built on the easy-to-use user interface of the early Polar impedance design system we are familiar with . This software contains various impedance modules, personnel can calculate the impedance result by selecting a specific module, inputting line width, line spacing, via layer thickness, copper thickness, Er value and other relevant data. The number of impedance control of a PCB is as few as 4 or 5 groups, and as many as dozens of groups. The control line width, interlayer thickness, copper thickness, etc. of each group are different. If you check the data one by one, and then manually enter the relevant parameters for calculation, Very time consuming and error prone.

Next, we will introduce how to use Orbotech's InPlan software, an industry-leading supplier of pre-production design engineering software solutions, to automatically perform impedance design and greatly improve pre-production work efficiency.

Orbotech's InPlan system can be connected with Si8000 to automatically calculate impedance based on the establishment of the following database: First, establish a complete material library in InPlan, which is classified by different manufacturers and models. It is built into the lamination thickness, substrate copper thickness, PP glue content and other data obtained according to the actual process parameters in the factory.

Then, establish the rules for calculating impedance in InPlan, such as the thickness of green oil, and the Undercut value can also be set according to different copper thicknesses, impedance modules, or inner and outer layers. The dielectric constant is mainly written in the formula according to the type of material and the difference of the impedance module. Impedance value and impedance line width tolerance are also written into rules through InPlan Rule. When calculating the impedance, InPlan automatically brings out the relevant impedance-affecting parameter values according to the rules, and calculates the optimal impedance result. And no matter how many sets of impedances there are, all the results can be obtained in a few seconds at the touch of a button.

4. Automatically generate impedance strips

If the customer does not design the impedance strip by himself, we need to design the impedance strip by ourselves and place it on the board edge or the broken edge (generally, placing the impedance strip on the broken edge requires the consent of the customer). The circuit board manufacturer designs an impedance strip on the side of the circuit board that meets all the characteristics and parameters of the customer's impedance control. By testing the impedance value of the impedance strip, it reflects that the circuit board meets the customer's impedance control requirements. To correctly test the impedance value in the board, the key lies in the design of the impedance strip.

The general PCB factory impedance design method is: MI engineers fill in the impedance attachment form based on the calculated impedance results, such as impedance value, reference layer, control line width, test hole, reference layer attributes (positive and negative), etc.

Then, CAM engineers manually make impedance bars according to the impedance table provided by MI, or input relevant impedance data through Script, and run the impedance bars with a program. Under normal circumstances, we design an impedance strip for one impedance value, and it usually takes about 10 minutes to make an impedance strip. Repeated manual data filling is very time-consuming and error-prone.

We can use Orbotech's InCoupon function to build the relevant rules of impedance strips into the system, which can automatically generate high-quality impedance strips and directly import them into the Genesis system. InCoupon adopts an embedded development architecture, which can detect the ideal drilling position between layers at the semi-finished product level, so that the drilling operation of the existing layer can be completely consistent with the Coupon circuit layer, integrating a complete CAM With engineering technology, the Coupon circuit, development structure and semi-finished product table for impedance measurement can be produced, and the optimal interconnection ability can be found for the Coupon level, and the complicated and manual calculation can be replaced by an intelligent operation wizard, which can be automatically performed in a few seconds. Calculate the reliable measurement circuit Coupon, and make the design of Coupon a simple and standard work.

5. Summary

The competition of PCB is becoming more and more fierce, and the sample delivery time is getting shorter and shorter. Impedance design accounts for a large proportion of pre-production work. How to shorten the impedance production time and make impedance matching that meets customer requirements is a must for the pre-production part. A question to consider. The emergence of InPlan and InCoupon provides a good help for impedance design. Of course, each PCB board factory has its own impedance calculation rules, layout methods and sizes will be different, and the InPlan system needs special personnel to develop and maintain it in order to truly realize its functions. But I believe that the automation of impedance design will become more and more popular in the front of PCB manufacturing.

- Previous:No

- Next:No