LED Printed circuit board Assembly

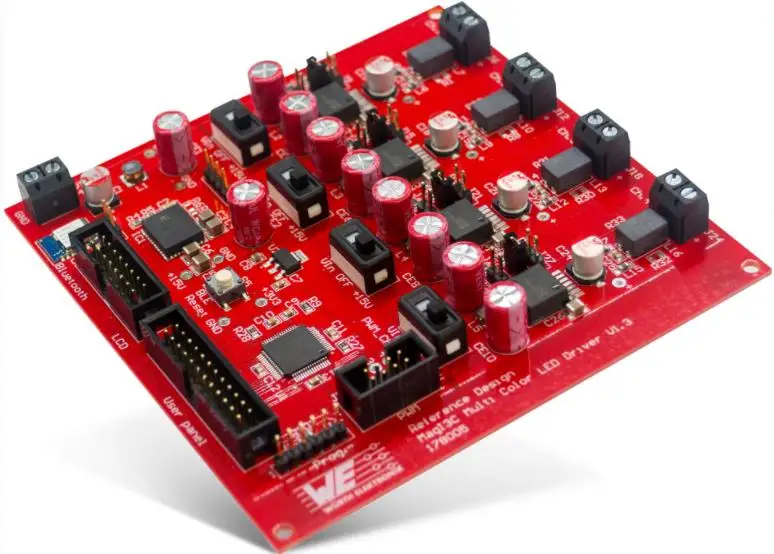

Name: LED PCB Assembly

Substrate: FR-4/CEM-1/CEM-3/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea

Light-emitting diode, referred to as LED for short, refers to a semiconductor diode made of compounds containing gallium (Ga), arsenic (As), phosphorus (P), nitrogen (N), etc., which can convert electrical energy into light energy.

Visible light can be radiated when electrons and holes recombine, so they can be used to make light-emitting diodes. It is used as an indicator light in circuits and instruments, or as a text or number display. Gallium arsenide diodes emit red light, gallium phosphide diodes emit green light, silicon carbide diodes emit yellow light, and gallium nitride diodes emit blue light. Due to chemical properties, it is divided into organic light-emitting diode OLED and inorganic light-emitting diode LED.

It is a type of semiconductor diode that converts electrical energy into light energy. Like ordinary diodes, light-emitting diodes are composed of a PN junction and also have unidirectional conductivity. When a forward voltage is applied to the light-emitting diode, the holes injected from the P region to the N region and the electrons injected from the N region to the P region are respectively connected to the electrons in the N region and the holes in the P region within a few microns near the PN junction. Hole recombination, resulting in spontaneous emission of fluorescence. The energy states of electrons and holes are different in different semiconductor materials. The amount of energy released when electrons and holes recombine varies, and the more energy released, the shorter the wavelength of light emitted. Commonly used are diodes that emit red, green, or yellow light. The reverse breakdown voltage of LEDs is greater than 5 volts. Its forward volt-ampere characteristic curve is very steep, and the current limiting resistor must be connected in series to control the current through the diode. The current limiting resistor R can be calculated by the following formula: R=(E-UF)/IF

Where E is the power supply voltage, UF is the forward voltage drop of the LED, and IF is the normal operating current of the LED. The core part of a light-emitting diode is a wafer composed of a P-type semiconductor and an N-type semiconductor. There is a transition layer between the P-type semiconductor and the N-type semiconductor, which is called a PN junction. In the PN junction of some semiconductor materials, when the injected minority carriers recombine with the majority carriers, the excess energy will be released in the form of light, thereby directly converting electrical energy into light energy. When a reverse voltage is applied to the PN junction, it is difficult for minority carriers to inject, so it does not emit light. This kind of diode made using the principle of injection electroluminescence is called light-emitting diode, commonly known as LED. When it is in the forward working state (that is, the forward voltage is applied to both ends), when the current flows from the anode to the cathode of the LED, the semiconductor crystal emits light of different colors from ultraviolet to infrared, and the intensity of light is related to the current.

The following are the inorganic semiconductor materials used in traditional light-emitting diodes and the colors they emit

White LED

At that time, Shuji Nakamura, who was working at Nichia Corporation in Japan, invented a blue LED with commercial application value based on wide bandgap semiconductor materials gallium nitride (GaN) and indium gallium nitride (InGaN). LED-like LEDs were widely used in the late 1990s. In theory, blue LEDs combined with original red LEDs and green LEDs can produce white light, but white LEDs are rarely produced in this way.

Most of the white LEDs currently produced are made by covering a blue LED (near-UV, wavelength 450nm to 470nm) with a light yellow phosphor coating. This yellow phosphor is usually obtained by doping cerium-doped yttrium Aluminum garnet (Ce3+:YAG) crystals are ground into powder and mixed in a dense binder. When the LED chip emits blue light, part of the blue light will be efficiently converted by the crystal into a mainly yellow light with a broad spectrum (the center of the spectrum is about 580nm). (Actually single-crystal Ce-doped YAG is seen as more of a scintillator than a phosphor.) Since the yellow light stimulates the red and green receptors in the naked eye, it mixes with the blue light of the LED itself, making it look like white light , and its color is often called "moonlight white". This method of making white LEDs was developed by Nichia Corporation and has been used in the production of white LEDs since 1996. To adjust the color of yellowish light, other rare earth metals terbium or gadolinium can be used to replace the cerium (Ce) doped in Ce3+:YAG, and even part or all of the aluminum in YAG can be replaced. Due to its spectral characteristics, red and green objects will not look as vivid under this kind of LED illumination as when illuminated by a broad-spectrum light source. In addition, due to the variation of production conditions, the color temperature of the finished product of this LED is not uniform, ranging from warm yellow to cool blue, so it will be distinguished according to its characteristics during the production process.

Another method of making white LEDs is a bit like a fluorescent lamp. The LEDs that emit near-ultraviolet light are coated with a mixture of two phosphors, one is europium that emits red and blue light, and the other emits green light. Copper and aluminum doped with zinc sulfide (ZnS). However, since ultraviolet rays can crack and deteriorate the epoxy resin in the adhesive, the production is more difficult and the service life is shorter. Compared with the first method, it is less efficient and generates more heat (because the StokesShift is larger), but the advantage is that the characteristics of the spectrum are better, and the light produced is more beautiful. And because of the higher power of the LED of ultraviolet light, although its efficiency is lower than that of the first method, the output brightness is similar. The latest method of making white LEDs does not use phosphors. A new approach is to grow an epitaxial layer of ZnSe on a zinc selenide (ZnSe) substrate. When electrified, its active zone will emit blue light and the substrate will emit yellow light, which is white light when mixed.

polarity

The longer one of the two leads of the light-emitting diode is the positive pole, which should be connected to the positive pole of the power supply. The two leads of some light-emitting diodes are the same length, but there is a raised tongue on the shell, and the lead near the tongue is the positive pole.

LED unidirectional conductivity

The LED can only be turned on (energized) in one direction, which is called forward bias (forward bias voltage). When the current flows, electrons and holes recombine in it to emit monochromatic light, which is called the electroluminescence effect. , and the wavelength and color of the light are related to the type of semiconductor material used and the elemental impurities doped. It has the advantages of high efficiency, long life, not easy to break, high switching speed, high reliability, etc. that traditional light sources cannot match. The luminous efficiency of white light LEDs has been significantly improved in recent years. At the same time, the purchase price per thousand lumens has also dropped significantly due to the competition among manufacturers entering the market. Although more and more people use LED lighting for offices, furniture, decoration, signboards and even street lights, technically, the photoelectric conversion efficiency of LEDs (the ratio of effective illuminance to electricity consumption) is still lower than that of new fluorescent lamps. The direction of the country's future development of civilian use.

Characteristic

Compared with incandescent bulbs and neon lamps, the characteristics of light-emitting diodes are: the working voltage is very low (some are only a few volts); Good, high reliability, long life; by modulating the strength of the passing current, the intensity of the luminescence can be easily modulated. Due to these characteristics, light-emitting diodes are used as light sources in some photoelectric control equipment and as signal displays in many electronic devices. Make its tube core into a strip shape, and use 7 strip-shaped light-emitting tubes to form a 7-segment semiconductor digital tube. Each digital tube can display 0-9, 10 Arabic numerals and A, B, C, D, E , F and other letters (must be case-sensitive).

Parameter

Several important aspects of LED optical parameters are: luminous flux, luminous efficiency, luminous intensity, light intensity distribution, and wavelength.

Luminous efficiency and luminous flux

Luminous efficiency is the ratio of luminous flux to electric power, and the unit is generally lm/W. Luminous efficiency represents the energy-saving characteristics of the light source, which is an important index to measure the performance of modern light sources.

Luminous Intensity and Light Intensity Distribution

The luminous intensity of an LED is a sign of its luminous intensity in a certain direction. Since the luminous intensity of LEDs varies greatly at different spatial angles, we have studied the luminous intensity distribution characteristics of LEDs. This parameter has great practical significance and directly affects the minimum viewing angle of the LED display device. For example, for large LED color displays in sports venues, if the distribution range of the selected LED single tube is very narrow, then the audience facing the display at a relatively large angle will see distorted images. And traffic sign lights also require a wider range of people to be able to identify.

Wavelength

For the spectral characteristics of LEDs, we mainly look at whether its monochromaticity is good, and we should also pay attention to whether the main colors of red, yellow, blue, green, and white LEDs are pure. Because in many occasions, such as traffic lights, the color requirements are relatively strict. However, it is observed that some LED signal lights in China are greenish blue, and red is deep red. From this phenomenon, our special research on the spectral characteristics of LEDs is Very necessary and meaningful.

Develop

History

Light-Emitting Diode (English: Light-Emitting Diode, referred to as LED) is a semiconductor electronic component that can convert electrical energy into light energy. This kind of electronic component appeared as early as 1962. In the early days, it could only emit red light with low luminosity. Later, other monochromatic light versions were developed. Today, the light that can be emitted has covered visible light, infrared rays and ultraviolet rays, and the luminosity has also increased to a considerable extent. of luminosity. And the use has also been used as indicator lights, display panels, etc. from the beginning; with the continuous advancement of technology, light-emitting diodes have been widely used in displays, TV lighting decoration and lighting.

Trend

With the continuous development of the industry, breakthroughs in technology, and vigorous promotion of applications, the luminous efficiency of LEDs is also constantly improving, and the price is constantly falling. The emergence of new combined tube cores has also continuously increased the power of a single LED tube (module). Through continuous efforts in research and development by peers, breakthroughs in new optical designs, and development of new lamp types, the situation of single products is expected to be further reversed. The improvement of the control software also makes the use of LED lighting more convenient. These gradual changes all reflect the broad prospects of LED light-emitting diodes in lighting applications.

LED is called the fourth-generation light source, which has the characteristics of energy saving, environmental protection, safety, long life, low power consumption, low heat, high brightness, waterproof, miniature, shockproof, easy dimming, concentrated beam, easy maintenance, etc., and can be widely used in Various indications, displays, decorations, backlights, general lighting and other fields.

LED advantages: high electro-optical conversion efficiency (close to 60%, green environmental protection, long life (up to 100,000 hours), low working voltage (about 3V), no loss of life after repeated switching, small size, less heat generation, high brightness, durable, Easy to adjust light, various colors, concentrated and stable beam, no delay in starting;

Disadvantages of LED: high initial cost, poor color rendering, low efficiency of high-power LED, constant current drive (requires a dedicated drive circuit). In contrast, there are certain defects in various traditional lighting.

Incandescent lamp: low electro-optic conversion efficiency (about 10%), short life (about 1000 hours), high heating temperature, single color and low color temperature;

Fluorescent lamps: low electro-optical conversion efficiency (about 30%), harmful to the environment (contains harmful elements such as mercury, about 3.5-5mg/piece), non-adjustable brightness (low voltage cannot start and glow), ultraviolet radiation, flickering phenomenon, slow start-up Slow, the price of rare earth raw materials increases (phosphor powder accounts for 60~70% of the cost from 10%), repeated switching affects the life; the volume is large.

High-pressure gas discharge lamps: large power consumption, unsafe use, short life, heat dissipation problems, mostly used for outdoor lighting.

On October 13, 2018, Huang Wei, an academician of the Chinese Academy of Sciences, and the team of Professor Wang Jianpu of the school increased the external quantum efficiency of perovskite light-emitting diodes (LEDs) to 20.7%, which was nearly half of the international counterparts. The results were recently published in the international academic journal "Nature "Main issue published

Status quo

In the 1990s, LED technology made great progress, not only the luminous efficiency surpassed incandescent lamps, but the light intensity reached the candlelight level, and the color also covered the entire visible spectrum from red to blue. The technological revolution at the light source level has led to various new applications, such as automotive signal lights, traffic lights, outdoor full-color large display screens, and special lighting sources.

Light-emitting diode applications:

With the progress of high brightness and multi-color of light-emitting diodes, the application field is also expanding. From the lower luminous flux indicator light to the display screen, from the outdoor display screen to the medium luminous flux power signal lamp and the white light source of special lighting, and finally Developed to the high luminous flux general lighting source in the upper right corner. The year 2000 is the dividing line of time. In 2000, all color signal display problems and lighting problems have been solved, and special lighting applications with low and medium luminous flux have begun, and as general lighting The application of white light lighting with high luminous flux seems to take some time, and it can only be realized by further increasing the luminous flux. Of course, this is also a process, which will be gradually realized with the increase of brightness and the decrease of price.

1. LED display

Since the mid-1980s, there have been monochrome and multi-color display screens, initially text screens or animation screens. In the early 1990s, the development of computer technology and integrated circuit technology enabled the video technology of LED display screens to be realized. TV images are directly displayed on the screen. Especially in the mid-1990s, blue and green ultra-high brightness LEDs were successfully developed and put into production quickly, which greatly expanded the application of outdoor screens, with an area ranging from 100 to 300 square meters. Currently, LED displays are used in stadiums, Squares, venues, even streets, and shopping malls have been widely used. The Nasdaq full-color screen on Times Square in the United States is the most famous. The screen area is 120 feet x 90 feet, which is equivalent to 1005m. It is made of green and red LEDs. In addition, it also accounts for a large proportion in securities market screens, bank exchange rate screens, interest rate screens, etc. Recently, it has also developed greatly in the information screens of expressways and elevated roads. Light-emitting diodes are used in this The application in this field has become large-scale, forming a new industry, and can expect a relatively stable growth.

2. Traffic lights

Navigation lights have used LEDs as light sources for many years, and the current work is to improve and perfect them. Road traffic lights have made great progress in recent years, with rapid technological development and rapid application development. China currently has about 40,000 sets of orders per year. In California, the United States replaced 50,000 sets of traditional light source signal lights with LED traffic lights within one year last year. According to the use effect, the effects of long life, power saving and maintenance-free are obvious. At present, the peak wavelength of LED light emission is red 630nm , yellow 590nm, green 505nm. It should be noted that the driving current should not be too large, otherwise the high temperature conditions under the summer sun will affect the life of the LED.

Recently, the LED airport special signal lights used in airports as beacon lights, floodlights and omnidirectional lights have also been successfully put into use, and the results are very good. It has independent intellectual property rights and has been approved for two patents. It has good reliability. , saving electricity, maintenance-free, can be popularized and applied to various airports, replacing the old signal lights that have been used for decades, not only high brightness, but also because of the good purity of LED light color, it is particularly bright and easy to identify signals.

Due to the large variety of signal lamps used in railways, the required light intensity and angle of view are also different. Currently, they are being intensively developed. It is estimated that they will be successfully developed and put into use one after another. Judging from the quantity, it is also a rather large market.

3. Car lights

Ultra-bright LEDs can be made into brake lights, tail lights and direction lights of cars, and can also be used for instrument lighting and interior lighting. It has obvious advantages over incandescent lamps in terms of vibration resistance, power saving and long life. It is used as brake lights , Its response time is 60ns, which is much shorter than the 140ms of incandescent lamps. Driving on a typical highway will increase the safety distance by 4-6m.

4. LCD backlight

As the backlight of liquid crystal display, LED can not only be used as green, red, blue, white, but also as color-changing backlight. Many products have entered the production and application stage. Recently, LEDs are used to make backlight for LCD screens on mobile phones. , which improves the grade of the product, and the effect is very good. The backlight of the 15in (1in≈2.5cm) LCD screen made of 8 blue, 24 green and 32 red Luxeon LEDs can reach 120W, 2500 lm, and the brightness is 18000nits (nits, cd/m2). The backlight source of the 22 LCD screen has also been made, which is only 6mm thick, not only has a good color mixing effect, but also has a color rendering index of more than 80. Although the large-scale backlight source is in the development stage at present, it has great potential .

5. Lighting

Due to the increase in the brightness of light-emitting diodes and the decline in prices, coupled with long life, power saving, driving and control are simpler than neon lights, not only can flash, but also change color, so single-color, multi-color and even LED lights made of ultra-high brightness LED The color-changing luminous column is matched with various luminous units of other shapes to decorate tall buildings, bridges, streets, squares and other landscape projects. The beam of light reaches more than 10,000 meters, and there are tens of thousands of colorful lights. It is currently being gradually promoted, and it is estimated that it will gradually expand and form a separate industry.

6. Lighting source

The LED light source used as a lighting source should be white light. The classification of white light LED light sources is shown in Table 3. At present, as white light LED lighting fixtures for military use, some varieties have been put into mass production. Since the LED light source has no infrared radiation, it is easy to conceal, and it is also It has the advantages of resistance to vibration, suitable for battery power supply, solid structure and easy to carry, and will have great development in special lighting sources. Lawn lamps and buried lamps used as folks have been produced on a large scale, and they are also used as microscopes. Field lighting, flashlights, surgeon's headlights, lighting for museums or art exhibitions, and reading table lamps. With the increase in luminous flux and the decline in prices, the application will gradually expand to complete the transition from special lighting to general lighting. It is estimated that 2005-2010 The annual meeting enters the field of general lighting

Classification

Light-emitting diodes can also be divided into ordinary monochromatic light-emitting diodes, high-brightness light-emitting diodes, ultra-high-brightness light-emitting diodes, color-changing light-emitting diodes, flashing light-emitting diodes, voltage-controlled light-emitting diodes, infrared light-emitting diodes, and negative resistance light-emitting diodes.

There are two kinds of LED control modes, constant current and constant voltage, and there are many dimming methods, such as analog dimming and PWM dimming. Most LEDs use constant current control, which can keep the LED current stable and not easily affected. The change of VF can prolong the service life of LED lamps.

Ordinary monochrome light emitting diode

Ordinary monochromatic light-emitting diodes have the advantages of small size, low working voltage, small working current, uniform and stable light emission, fast response speed, long life, etc., and can be driven by various DC, AC, pulse and other power sources to light up. It is a current-controlled semiconductor device, and it needs to be connected in series with a suitable current-limiting resistor.

The luminous color of an ordinary monochromatic light-emitting diode is related to the wavelength of light, and the wavelength of light depends on the semiconductor material used to manufacture the light-emitting diode. The wavelength of the red light-emitting diode is generally 650~700nm, the wavelength of the amber light-emitting diode is generally 630-650 nm, the wavelength of the orange light-emitting diode is generally about 610-630 nm, the wavelength of the yellow light-emitting diode is generally about 585 nm, and the green light-emitting diode The wavelength of the diode is generally 555~570 nm. Commonly used domestic ordinary monochromatic light-emitting diodes include BT (factory standard model) series, FG (ministry standard model) series and 2EF series, see Table 4-26, Table 4-27 and Table 4-28.

Commonly used imported ordinary monochromatic light-emitting diodes include SLR series and SLC series.

High Brightness Monochrome Light Emitting Diode

High-brightness monochromatic light-emitting diodes and ultra-high-brightness monochromatic light-emitting diodes use different semiconductor materials from ordinary monochromatic light-emitting diodes, so the intensity of light is also different.

Usually, materials such as gallium aluminum arsenide (GaAlAs) are used for high-brightness monochrome light-emitting diodes, materials such as gallium indium arsenide phosphide (GaAsInP) are used for ultra-high-brightness monochrome light-emitting diodes, and gallium phosphide (GaP) is used for ordinary monochrome light-emitting diodes. ) or gallium arsenide phosphide (GaAsP) and other materials.

The main parameters of commonly used high-brightness red light-emitting diodes are shown in Table 4-29, and the main parameters of commonly used ultra-high-brightness monochromatic light-emitting diodes are shown in Table 4-30.

Color Changing LED

Color-changing light-emitting diodes are light-emitting diodes that can change the color of their light. Color-changing light-emitting diodes can be divided into two-color light-emitting diodes, three-color light-emitting diodes and multi-color (red, blue, green, white four colors) light-emitting diodes.

Color-changing LEDs can be divided into two-terminal color-changing LEDs, three-terminal color-changing LEDs, four-terminal color-changing LEDs and six-terminal color-changing LEDs according to the number of pins.

The commonly used two-color LEDs are 2EF series and TB series, and the commonly used three-color LEDs are 2EF302, 2EF312, 2EF322 and other models.

Blinking light emitting diode

Blinking light-emitting diode (BTS) is a special light-emitting device composed of CMOS integrated circuits and light-emitting diodes, which can be used for alarm indication and undervoltage and overvoltage indication.

When the flashing light-emitting diode is in use, there is no need to connect other components, as long as an appropriate DC working voltage (5V) is applied to both ends of its pins, it can flash and emit light.

Voltage Controlled Light Emitting Diodes

Ordinary light-emitting diodes are current-controlled devices, and a current-limiting resistor with an appropriate resistance value needs to be connected in series when used. The voltage-controlled light-emitting diode (BTV) is made by integrating a light-emitting diode and a current-limiting resistor, and can be directly connected to both ends of the power supply when in use. make ordinary red light emitting diode

The voltage can work in 3 volts - 10 volts, such as YX503URC, YX304URC, YX503BRC voltage-type LED light-emitting diodes, providing greater choices for engineering and technical developers.

Infrared light emitting diode

Infrared light-emitting diode, also known as infrared emitting diode, is a light-emitting device that can directly convert electrical energy into infrared light (invisible light) and radiate it out. It is mainly used in various light control and remote control transmitting circuits.

The structure and principle of infrared light-emitting diodes are similar to ordinary light-emitting diodes, but the semiconductor materials used are different. Infrared light-emitting diodes usually use materials such as gallium arsenide (GaAs), gallium aluminide arsenide (GaAlAs), and are packaged in fully transparent or light blue or black resin.

Commonly used infrared light-emitting diodes include SIR series, SIM series, PLT series, GL series, HIR series and HG series.

Battery led light

iViTi On, has a built-in battery that keeps it glowing for up to 3 hours. When powered, the battery charges and the bulb glows normally. In case of a power outage, the bulb automatically switches to battery mode.

Measurement

General inspection

Ordinary light-emitting diode detection

(1) Check with a multimeter. Using a pointer multimeter with a ×10kΩ block can roughly judge whether the light-emitting diode is good or bad. Normally, the forward resistance of the diode is tens to 200kΩ, and the reverse resistance is ∝. If the forward resistance value is 0 or ∞, and the reverse resistance value is small or 0, it is easy to be damaged. This detection method cannot actually see the luminescence of the luminous tube, because the ×10kΩ block cannot provide a large forward current to the LED.

If you have two pointer multimeters (preferably the same model), you can better check the light-emitting diodes. Connect a wire from the "+" post of one of the multimeters to the "-" post of the other meter. The remaining "-" pens are connected to the positive electrode (P area) of the luminous tube under test, and the remaining "+" pens are connected to the negative electrode (N area) of the luminous tube under test. Both multimeters are set to ×10kΩ block. Under normal circumstances, it can emit light normally after being connected. If the brightness is very low or even does not emit light, both multimeters can be dialed to ×1mΩ; if it is still very dark or even does not emit light, it means that the performance of the light-emitting diode is poor or damaged. It should be noted that the two multimeters cannot be placed at ×1mΩ at the beginning of the measurement, so as to avoid excessive current and damage the light-emitting diodes.

(2) External power supply measurement. The optical and electrical characteristics of light-emitting diodes can be measured more accurately with a 3V regulated source or two dry batteries in series and a multimeter (either pointer or digital). To this end, the circuit can be connected as shown in Figure 10. If the measured VF is between 1.4 and 3V, and the brightness of the light is normal, it means that the light is normal. If VF=0 or VF≈3V is measured and there is no light, it means that the luminescent tube is broken.

Detection of infrared light-emitting diodes

Due to the infrared light-emitting diode, it emits 1-3μm infrared light, which cannot be seen by the naked eye. Usually, the emission power of a single infrared light-emitting diode is only a few mW, and the angular distribution of the luminous intensity of different types of infrared LEDs is also different. The forward voltage drop of infrared LED is generally 1.3 ~ 2.5V. Because the infrared light emitted by it is invisible to the human eye, the detection method using the above-mentioned visible light LED can only determine whether the forward and reverse electrical characteristics of its PN junction are normal, but cannot determine whether its luminescence is normal or not. For this reason, it is best to prepare a photosensitive device (such as 2CR, 2DR silicon photocell) as a receiver. Use a multimeter to measure the change of the voltage across the battery. To judge whether the infrared LED emits infrared light after adding an appropriate forward current.

Brightness

Install and debug the light intensity standard lamp, LED and silicon photodiode equipped with V (λ) filter on the optical bench, especially strictly adjust the position of the filament, the position of the LED light emitting part and the position of the receiving surface.

Calibrate the silicon photodiode with the light intensity standard lamp first, C=E/S

Where Rs=Is/Ds

Ds is the distance between the standard lamp and the receiver, Is is the light intensity of the standard lamp, Rs is the response of the standard lamp.

Et=C R t where E t is the illuminance of the LED under test, R t is the response of the LED under test, then the light intensity I t of the LED is: I t=E t Dt

Where Dt is the distance between the LED and the receiving surface.

For LED, its light-emitting surface is in the shape of a dome, and the light distribution is very special, so at different measurement distances, the light intensity value will change, which deviates from the inverse square law of distance, even if the measurement distance is fixed, but due to the acceptance Depending on the receiving area of the sensor, the light intensity value will also change. Therefore, in order to improve the measurement accuracy, it is better to fix the measurement distance and the size of the receiving area relatively. For example, the measurement distance is 316mm as recommended by GIE, and the receiver area is fixed at 10×10mm. Under the same measurement distance, the LED rotation angle is different, and its light intensity will change accordingly. Therefore, in order to obtain the best value, it is best to read the maximum reading R t.

Luminous flux

The luminous flux measurement is carried out on the turntable of the goniophotometer, on which the LED is installed. The turntable rotates ±90 degrees around the vertical axis on its horizontal plane, and the LED rotates 360 degrees around the photometric axis on the vertical plane. The control of the rotation angle on the horizontal and vertical planes is realized by stepping motors. The turntable moves freely on the guide rail. When measuring standard lamps, the turntable should leave the guide rail.

When measuring, the large turntable rotates around the vertical axis on the horizontal plane, with a step angle of 0.9°, 90° in the positive direction and 90° in the reverse direction. The LED itself is also rotating. At each horizontal angle, the signal is collected every 18° on the vertical plane. After turning 360°, a total of 20 data are collected, and the total luminous flux is calculated according to the following formula.

If the large disk rotates 0° to 90°, the small disk can rotate 0° to 360°. However, when the large plate rotates 0°~90°, there may be errors caused by uneven (asymmetric) LED installation, so the best solution is to rotate the large plate -90°~0°~90°, and the small plate still rotates 0°~ 360°, take the average of the illuminance values at angles whose absolute values are equal in the two ranges of 0° to 90° and -90° to 0°, and take the average value as the value within 0° to 90°.

The second method of LED total luminous flux measurement is the integral method. The advantage of this method is that it is simple and easy to implement, but the measurement accuracy is not high. The calculation method of the total luminous flux of the LED is as follows, first calculate the luminous flux Φs of the standard lamp (light intensity value I s) entering the integrating sphere at a distance of 1 distance from the incident window of the integrating sphere (incidence window area A), Φs=I s · A /I 2

Read out the photocurrent signal i s on the receiver, then place the LED on the window, and read out the corresponding receiver photocurrent signal it, then the total luminous flux Φ of the LED is:

Φt=It/IsΦs·K where K is the color correction coefficient.

Performance requirements

1. High reliability is especially like the driving power supply of LED street lamps, which are installed at high altitudes, making maintenance inconvenient and costly.

2. High-efficiency LEDs are energy-saving products, and the efficiency of the driving power supply must be high. It is especially important for the structure where the power supply is installed in the lamp. Because the luminous efficiency of LED decreases with the increase of LED temperature, the heat dissipation of LED is very important. The efficiency of the power supply is high, its power consumption is small, and the heat generated in the lamp is small, which also reduces the temperature rise of the lamp. It is beneficial to delay the light decay of LED.

3. High power factor The power factor is the requirement of the grid for the load. Generally, there is no mandatory index for electrical appliances below 70 watts. Although the low power factor of a single electrical appliance with low power has little impact on the power grid, but when everyone lights up at night, the concentration of similar loads will cause serious pollution to the power grid. For 30W~40W LED drive power, it is said that in the near future, there may be certain index requirements for power factor.

4. There are two common driving methods: one is a constant voltage source for multiple constant current sources, and each constant current source supplies power to each LED individually. In this way, the combination is flexible, and the failure of one LED will not affect the work of other LEDs, but the cost will be slightly higher. The other is direct constant current power supply, LEDs run in series or in parallel. Its advantage is that the cost is lower, but the flexibility is poor, and it is necessary to solve the problem that a certain LED failure does not affect the operation of other LEDs. These two forms coexisted for a period of time. The multi-channel constant current output power supply method will be better in terms of cost and performance. Maybe it will be the mainstream direction in the future.

5. Surge protection The ability of LED to resist surge is relatively poor, especially the ability to resist reverse voltage. Strengthening protection in this area is also important. Some LED lights are installed outdoors, such as LED street lights. Due to the swaying of the grid load and the induction of lightning strikes, various surges will invade from the grid system, and some surges will cause damage to the LED. Therefore, the LED drive power supply must have the ability to suppress the intrusion of the surge and protect the LED from being damaged.

6. Protection function In addition to the conventional protection function of the power supply, it is best to add LED temperature negative feedback to the constant current output to prevent the LED temperature from being too high.

7. In terms of protection, the lamps are installed outside, the power supply structure should be waterproof and moisture-proof, and the shell should be light-resistant.

8. The life of the driving power supply should match the life of the LED.

9. It must meet the requirements of safety regulations and electromagnetic compatibility.

Application

In the past 10 years from the advent of LED in the 1960s to the 1980s, LEDs only had red, yellow, and green colors, and the luminous efficiency was very low (only about 1 lm/W), the brightness was relatively low, and the price was high. Just use it as an indicator light for electronics. From the perspective of LED development and application history, this period is the indication application stage of LED.

1. AC power light

As long as the circuit is connected to a 220V/50Hz AC power supply line, the LED will be lit to indicate that the power is on. The resistance value of the current limiting resistor R is 220V/IF.

2. AC switch indicator light

The circuit uses LED as the switch indicator light of incandescent lamp. When the switch is disconnected and the bulb is extinguished, the current forms a loop through R, LED and bulb EL, and the LED lights up, which is convenient for people to find the switch in the dark. At this time, the current in the loop is very small, and the bulb will not light up. When the switch is turned on, the bulb is lit and the LED is off.

3. AC power outlet light

A circuit using a bi-color (common cathode) LED as an indicator light for an AC outlet. The power supply of the socket is controlled by the switch S. When the red LED is on, the socket has no power; when the green LED is on, the socket has power.

4. Indicator light of fuse holder

The LED is used as a circuit for the indicator light of the fuse socket of the factory equipment distribution box. When the fuse is intact, the LED is off; when the fuse is blown, the LED will be lit to indicate to the user which fuse has been blown for replacement. This is very convenient for porcelain core fuses that cannot be observed with the naked eye.

5. LED advertising signboard lights

6. LED monochrome or color display

Generally, the monochrome display is used to display single-line Chinese characters, and the color display is used for outdoor large-screen TVs.

7. LED Street Lights

8. LED car signal lights and LED electric vehicle lights

Kingford supports LED PCB Assembly business, we are a professional PCBA one-stop assembly factory, welcome to place an order.

Name: LED PCB Assembly

Substrate: FR-4/CEM-1/CEM-3/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea