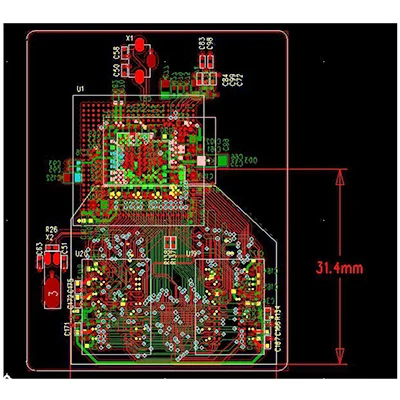

RF equipment PCB/PCBA design

Name: RF equipment PCB/PCBA design

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

1. Introduction to RF PCB Design

In the wireless communication system, only a small part of the front-end circuit works in the radio frequency stage, which is commonly known as the radio frequency front-end circuit. The rest of the circuit is used for low frequency baseband analog and digital signal processing. RF front-end circuits generally include low-noise amplifiers, mixers and power amplifiers. Although the number of components in this part of the circuit is much less than that of the baseband circuit, it is still the key to the success or failure of the entire system.

Similar to the octagon rule for analog IC design, RF PCB design requires analog signal processing at wide dynamic range and high frequencies. Therefore, RF PCB design also has its own hexagon rule. Noise, linearity, supply voltage, gain, operating frequency and power are the most important metrics in an RF PCB. In practical designs, any two or more of these parameters will constrain each other, resulting in multidimensional optimization problems. Such compromises and mutual constraints bring many problems to the design of RF PCBs. Often it takes the intuition and experience of the RF designer to arrive at a better compromise.

Second, the application field of RF PCB

(1) Base station RF circuit board

(2) Mobile phone RF circuit board

(3) Wireless Local Area Network (WLAN) RF PCB

(4) Global Positioning System (GPS) RF circuit board

(5) Radio Frequency Tag (RFID) RF PCB

(6) Internet of Things (IOT) RF PCB

Name: RF equipment PCB/PCBA design

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

- Previous:No

- Next:GPS Base Station PCB/PCBA Design